Ceramic strengthening treatment method based on 3D printing

A 3D printing and strengthening treatment technology, applied in the field of ceramic strengthening, can solve the problems of increasing ceramic 3D printing products, difficult cleaning, and large shrinkage, and achieve the effect of effectively controlling shrinkage rate, increasing skeleton density, and reducing ceramic damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

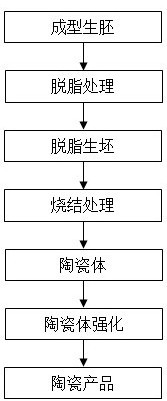

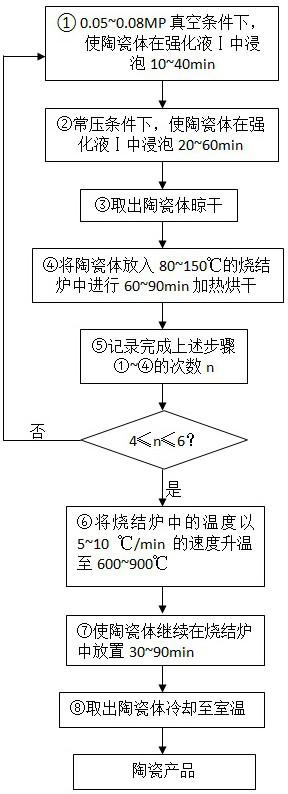

[0030] This example discloses a method for strengthening treatment of ceramics based on 3D printing. As a basic embodiment of the present invention, it includes degreasing the formed green body after ceramic 3D printing to obtain a degreased green body; The degreased green body is sintered to obtain a ceramic body; finally, the ceramic body is strengthened. Among them, the formed green body, the degreased green body and the ceramic body all include a body part and a body support part, and the specific steps for strengthening the ceramic body are as follows:

[0031]Step 1, put the ceramic body into the container equipment equipped with strengthening liquid I, and vacuumize the inside of the container equipment to 0.05~0.08MP, so that the ceramic body is soaked in the strengthening liquid I for 10~40min;

[0032] Step 2, release the internal pressure of the container equipment to normal pressure, and then soak the ceramic body in the strengthening liquid Ⅰ for 20-60 minutes;

...

Embodiment 2

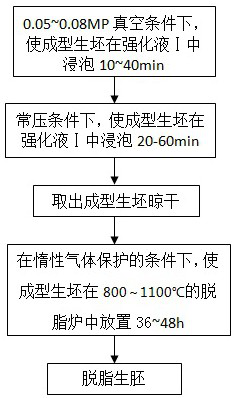

[0037] This example discloses a ceramic strengthening treatment method based on 3D printing. As a preferred embodiment of the present invention, specifically, the molded body is sequentially subjected to degreasing treatment, sintering treatment and ceramic body strengthening treatment, wherein the degreasing treatment Including the preliminary strengthening of the green body and the degreasing of the green body, the specific steps are as follows:

[0038] Preliminary strengthening of the green body:

[0039] Step 1: Put the formed green body into a container equipped with strengthening liquid Ⅰ, and vacuum the interior of the container to 0.05~0.08MP, so that the formed green body is soaked in the strengthening liquid Ⅰ for 10~40min; wherein, strengthening liquid Ⅰ It is one of silica sol, aluminum sol and ethyl silicate hydrolyzate;

[0040] Step 2: Release the internal pressure of the container equipment to normal pressure, and then soak the formed green body in the streng...

Embodiment 3

[0051] This example discloses a ceramic strengthening treatment method based on 3D printing. As a preferred embodiment of the present invention, specifically, the molded body is sequentially subjected to degreasing treatment, sintering treatment and ceramic body strengthening treatment, wherein the degreasing treatment Including the preliminary strengthening of the green body and the degreasing of the green body, the specific steps are as follows:

[0052] Preliminary strengthening of the green body:

[0053] Step 1: Put the shaped green body into a container equipped with strengthening liquid I, and vacuumize the inside of the container to 0.06MP, so that the shaped green body is soaked in the strengthening liquid I for 30 minutes;

[0054] Step 2: Release the internal pressure of the container equipment to normal pressure, and then soak the formed green body in the strengthening liquid Ⅰ for 30 minutes;

[0055] Step 3: Take the formed green body out of the strengthening li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com