Process method and optimized structure for eliminating shrinkage porosity of side cover of valve body of steering gear

A technology to optimize the structure and steering gear, which is applied in the direction of manufacturing tools, metal processing equipment, casting molding equipment, etc., can solve the problems of reducing the service life and stability of castings, unreasonable gating system design, unreasonable riser design, etc. Achieve the effects of increasing the process subsidy layer, ensuring the appearance, and increasing the success rate of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A process method for eliminating shrinkage of the side cover of the steering gear valve body, the operation method is as follows:

[0027] ①Increase the diameter of the casting riser and valve body riser on the casting body of the steering gear side cover and the casting body of the steering gear valve body, so as to increase the flow rate of molten iron at the riser and make the casting shrinkage loose;

[0028] ② Change the size of the weight-reducing groove, increase the internal cavity of the weight-reducing groove, and reduce the wall thickness at the corresponding position of the casting through increasing the size of the weight-reducing groove, so that the casting can solidify quickly;

[0029] ③Increase the inclination angle of the draft layer, combined with the increase in the size of the weight-reducing groove, to make the weight-reducing groove better out of the mold and ensure the appearance of the casting;

[0030] ④ Add a process subsidy layer on the outer...

Embodiment 2

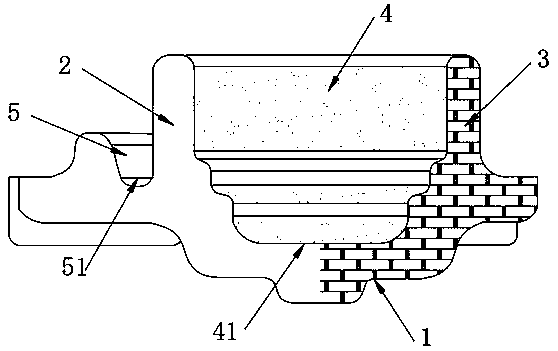

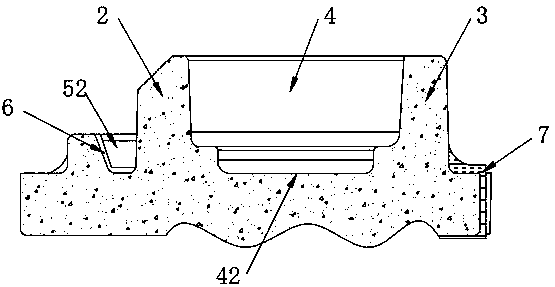

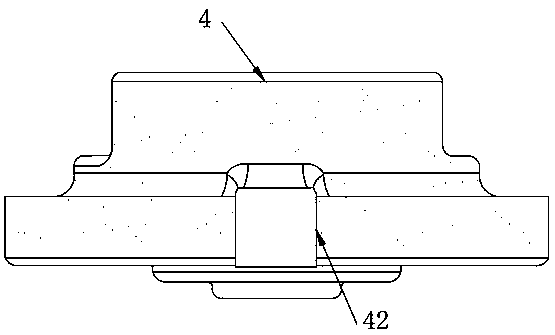

[0032] see Figure 1~5 , an optimized structure for eliminating shrinkage of the side cover of the steering gear valve body, including a side cover casting body 1 and a valve body casting body 8, a weight reducing groove 5 is opened on the left top of the side cover casting body 1, and the weight reducing groove 5 The increase in size can effectively reduce the wall thickness at B station 2, so that this position can be solidified quickly, and the increase in the size of the weight-reducing groove 5 enables the product to be released from the mold better, thus ensuring the appearance of the casting. The casting cap 4 is fixedly installed in the middle of the casting body 1 of the side cover, the B station 2 is set on the left side of the casting cap 4, the A station 3 is set on the right side of the casting cap 4, and the outer side of the weight reducing groove 5 is bonded A draft layer 6 is fixed, a subsidy layer 7 is fixed on the right outer wall of the side cover casting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com