Trimming and punching die

A technology for edge trimming and punching and punching punch, which is applied in the field of punching die and edge trimming, can solve the problems of low processing efficiency, high production cost, high labor intensity, etc., so as to improve production efficiency, reduce production cost and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

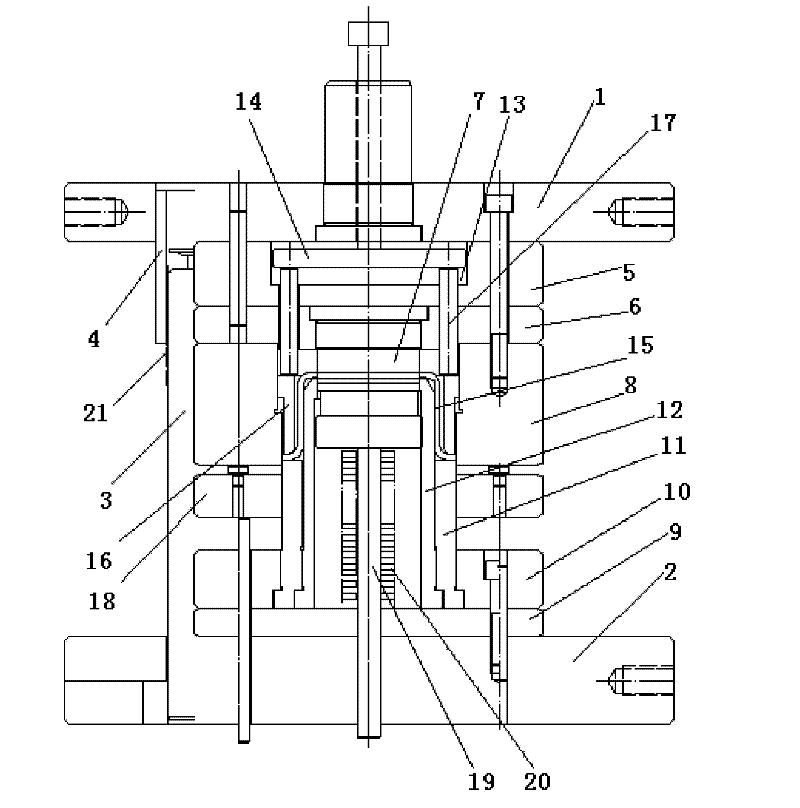

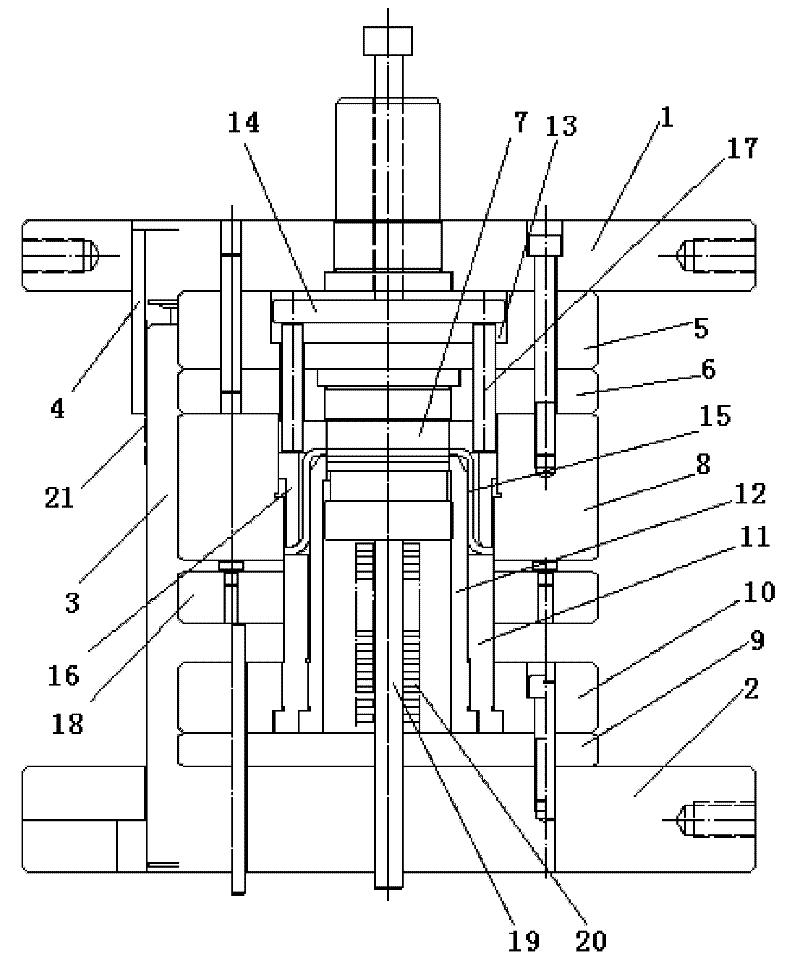

[0010] Referring to the accompanying drawings, the trimming and punching die includes an upper template 1 and a lower template 2, and a guide post 3 and a guide sleeve 4 that slide and cooperate with each other are respectively fixed between the upper template 1 and the lower template 2, between the guide post and the guide sleeve There are balls 21 between them, and the lower end surface of the upper template 1 is fixedly installed with a punch backing plate 5 and a punch fixing plate 6 in sequence, and a punching punch 7 and a trimming punch are fixedly installed at the center and edge of the punch fixing plate 6 respectively. Die 8, die backing plate 9, die fixing plate 10 are fixed on the upper end surface of lower template 2, and the die fixing plate is matched with trimming punch 11, punching die 12 successively, punching punch 7 and punching hole The cavity of the die 12 is matched, and the trimming punch 11 is matched with the cavity of the trimming die 12; the punch ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com