Device for rotating material in material production equipment

A technology for production equipment and rotating devices, applied in the directions of transportation and packaging, conveyor objects, electrical components, etc., can solve the problems of extending the length of the production line, increasing the cost of equipment, etc., to improve the speed of the process, save the cost of equipment, and reduce the production line. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

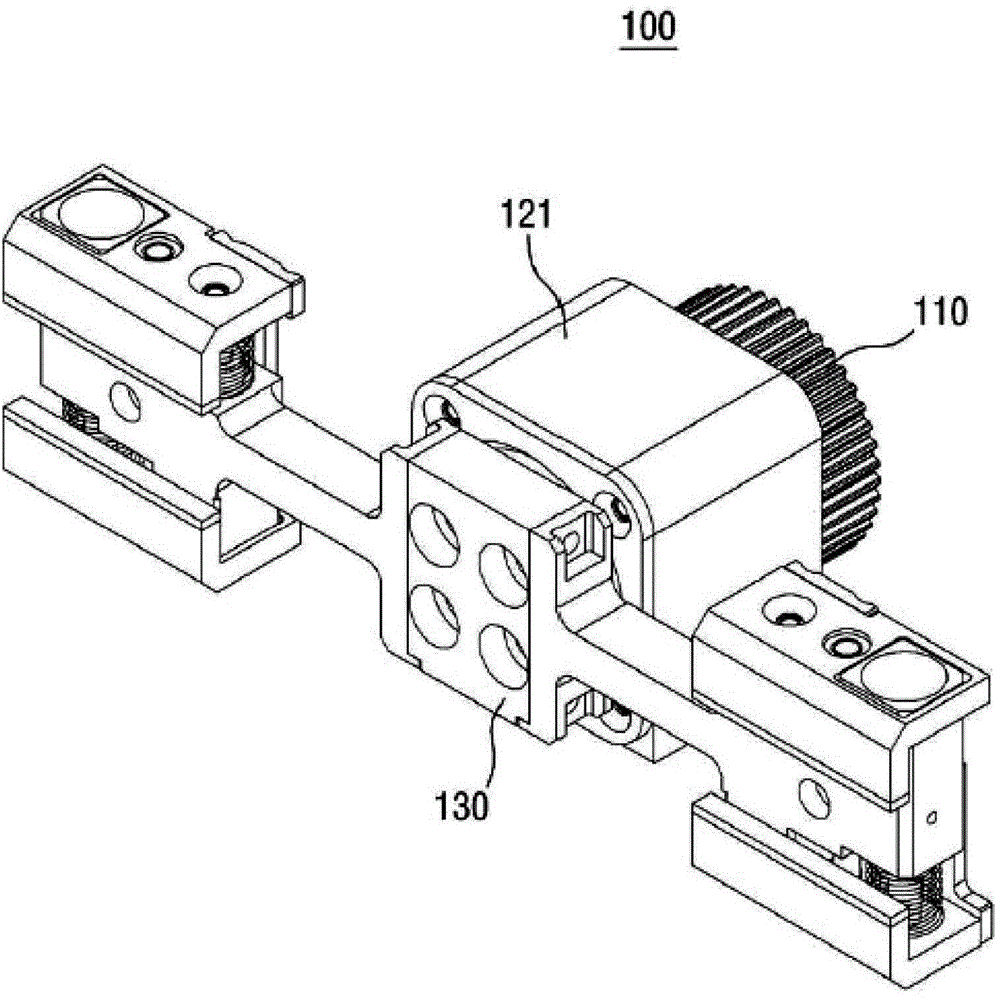

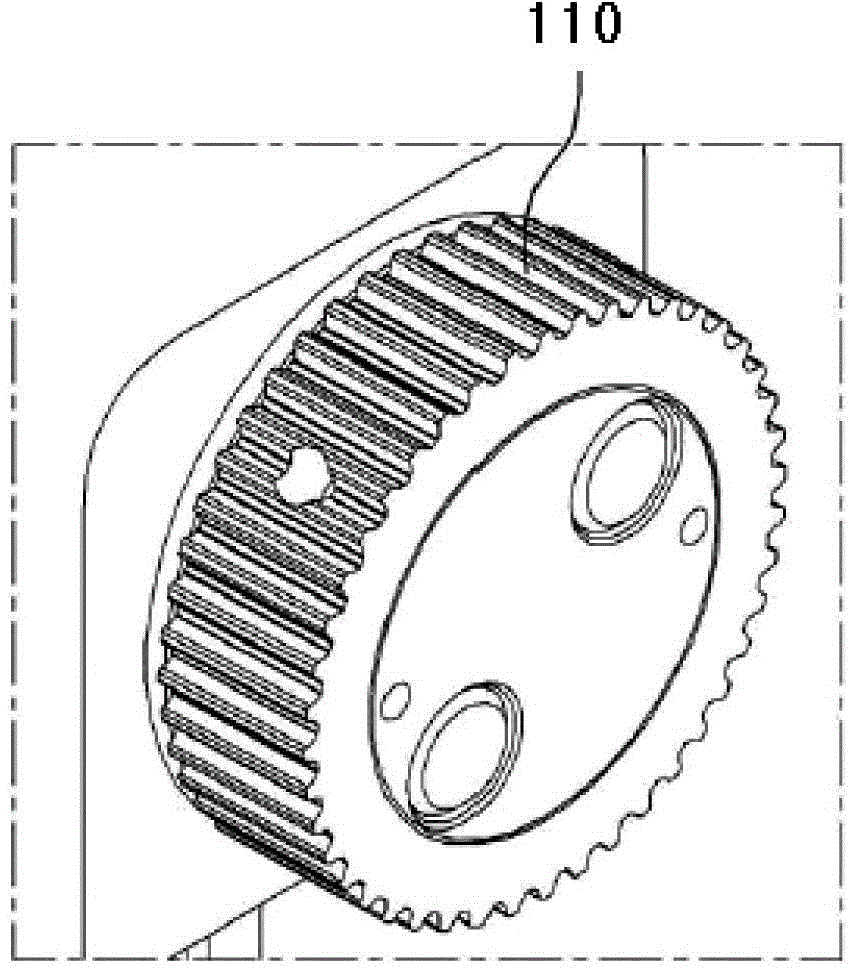

[0056] First, the means for rotating the material in the material production facility performs a corresponding production process in the material production facility as a single independent device for producing a predetermined material and rotates the material at a predetermined point of time when the material enters the material production facility.

[0057] That is to say, the aforementioned device for rotating the material in the material production equipment may include a rotating device, a conveying device (conveyor equipment) and a control module.

[0058] Next, in order to specifically describe the present invention, the case where the aforementioned material is a substrate will be described in detail as an example. For this reason, the material production equipment will be named substrate production equipment when describing the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com