Pattern forming apparatus and method, mfg. method of conducting film wiring and electronic device

A manufacturing method and technology of conductive film, which are used in conductive pattern formation, discharge tube/lamp manufacturing, electric solid device, etc., can solve problems such as disconnection, short circuit, liquid retention, etc., and achieve simplified process, less waste, and easy control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

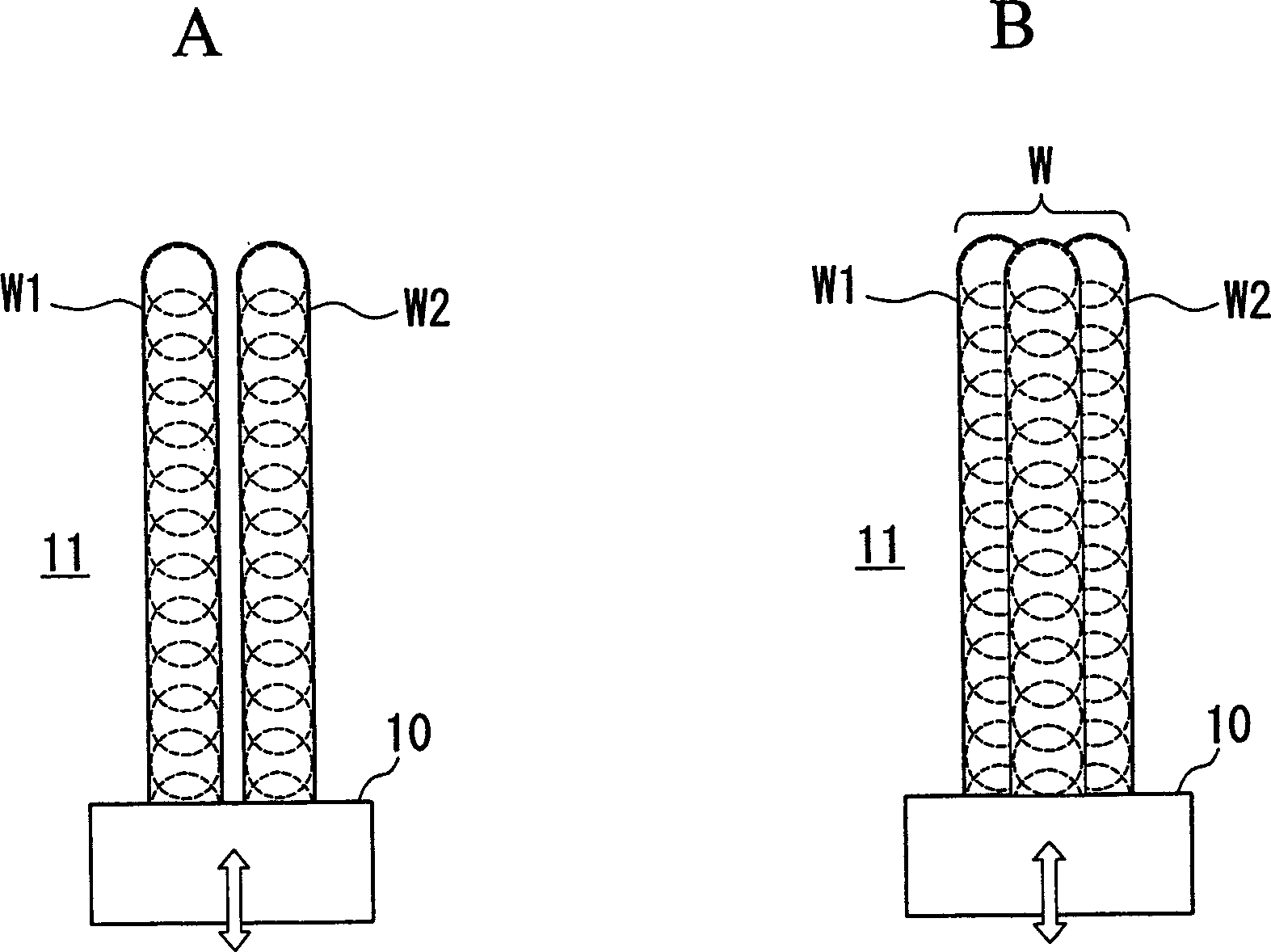

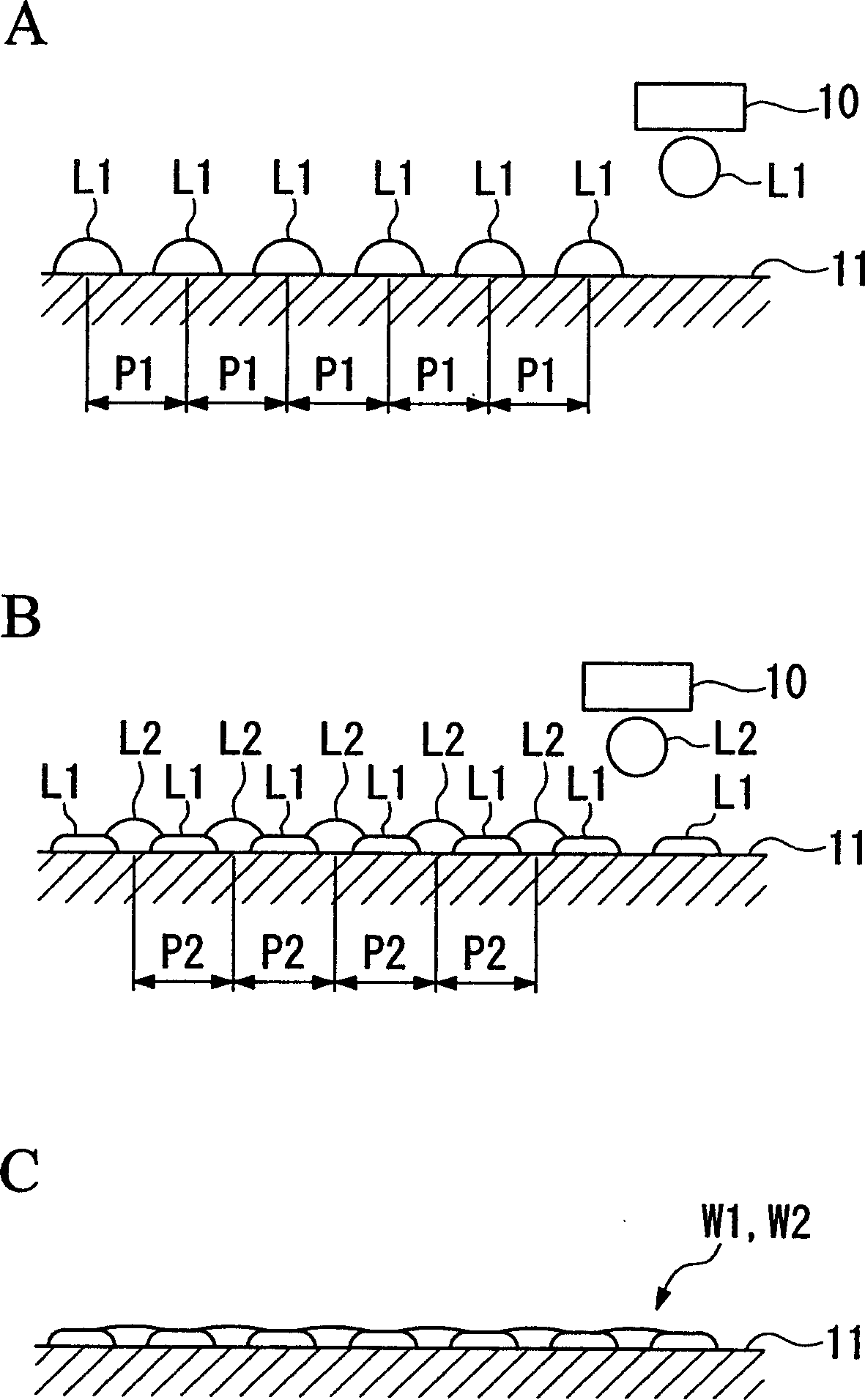

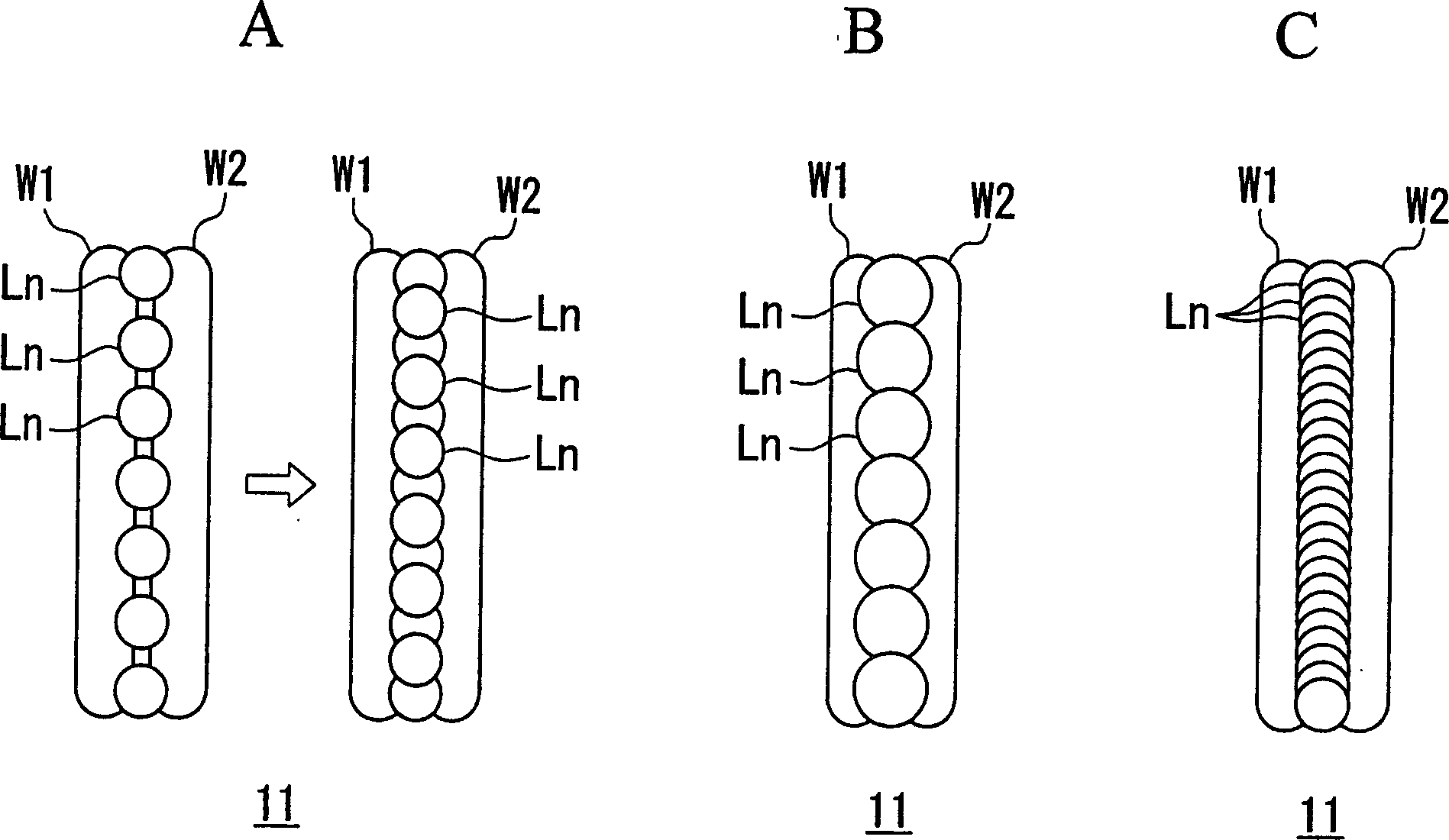

[0046] Hereinafter, as an example of an embodiment of the present invention, a method of forming conductive film wiring on a substrate will be described. The wiring forming method of this embodiment is to arrange a liquid material for wiring of a conductive film on a substrate, and to form a pattern of a conductive film for wiring on the substrate, including a surface treatment process, a material arrangement process, and a heat treatment / light treatment process, etc. . In addition, in disposing the liquid material, a droplet discharge device is used, and a liquid discharge method in which a liquid material is discharged as droplets from a nozzle of a discharge head, a so-called inkjet method, is employed. Here, the discharge method of the droplet discharge device may be a piezoelectric discharge method in which a liquid material (fluid) is discharged by changing the volume of a piezoelectric element, or the like.

[0047] As the substrate for conductive film wiring, various ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com