Substrate processing apparatus and substrate positioning device

A substrate processing device and a technology for substrates, which can be applied to devices that apply liquid to surfaces, machines that arrange working positions in sequence, and coating of discharge tubes, etc. , to achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below, we refer to the attached Figure 1 Preferred embodiments of the present invention will be described above.

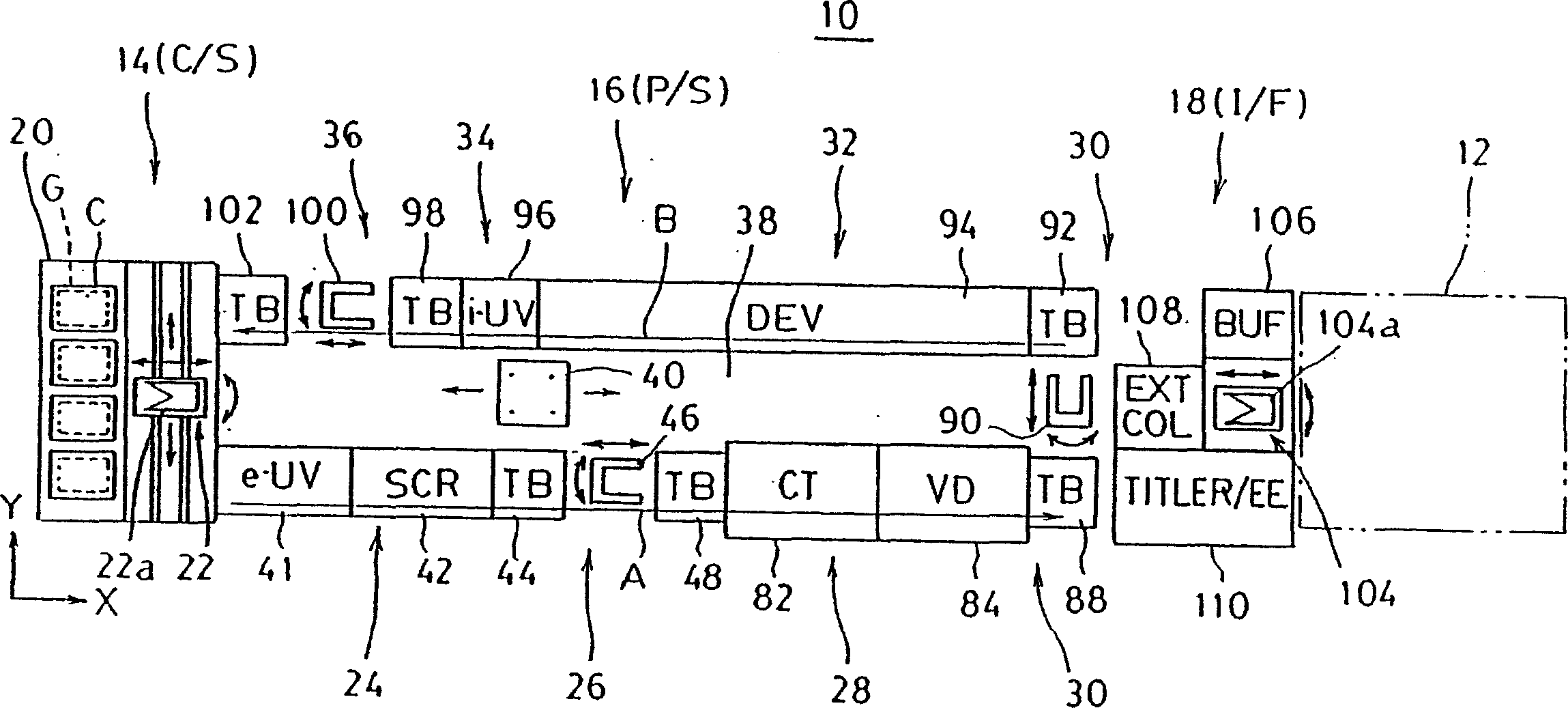

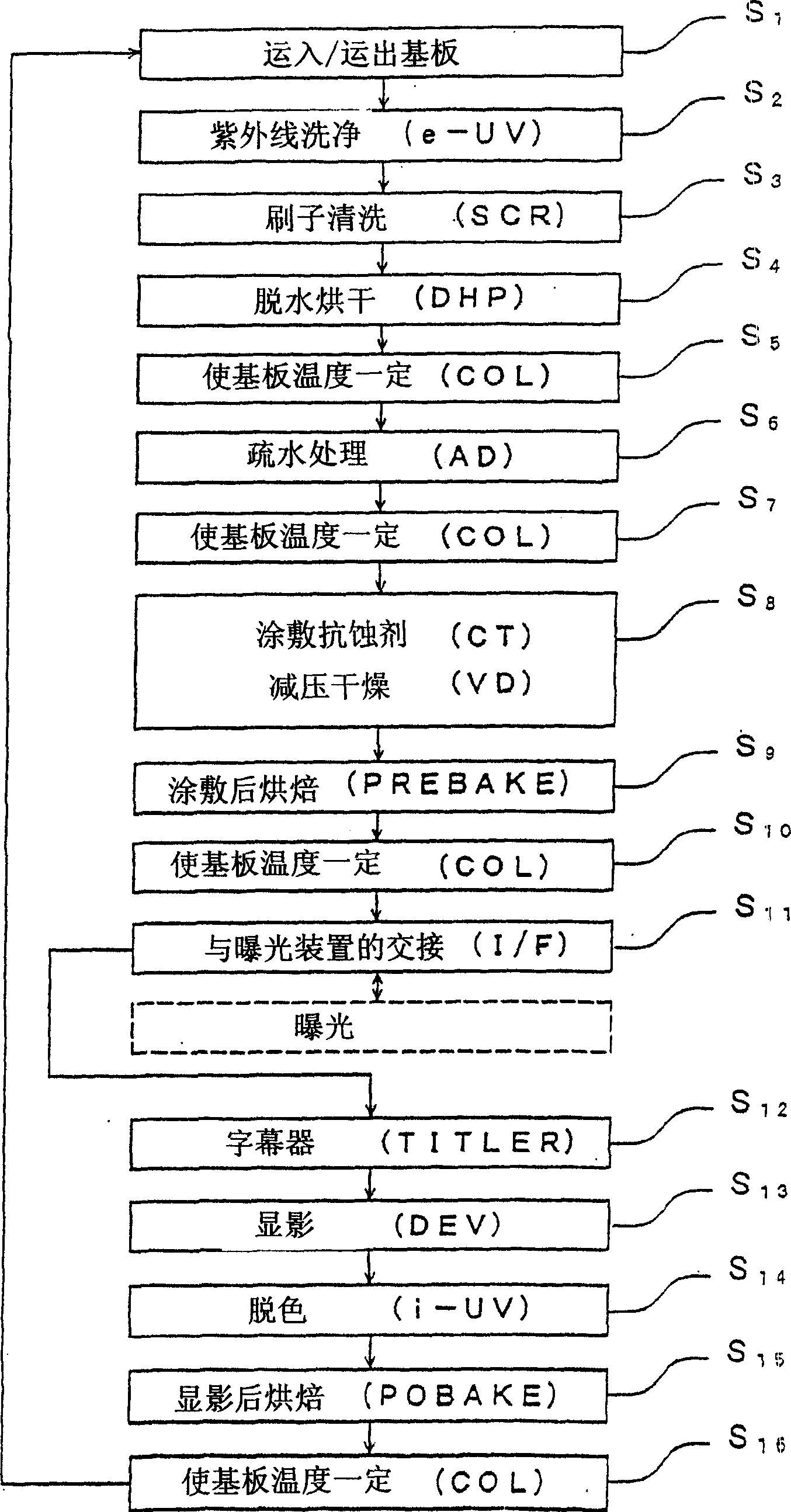

[0052] figure 1 A coating and development processing system is shown as an example of the configuration of a substrate processing apparatus to which the present invention can be applied. The coating and development processing system 10 is set in a clean room, for example, the LCD substrate is used as the substrate to be processed, and the cleaning, resist coating, pre-baking, development and post-processing in the photolithography process are performed in the LCD manufacturing process. A series of processes such as baking. Exposure processing is performed by an external exposure device 12 provided adjacent to the processing system.

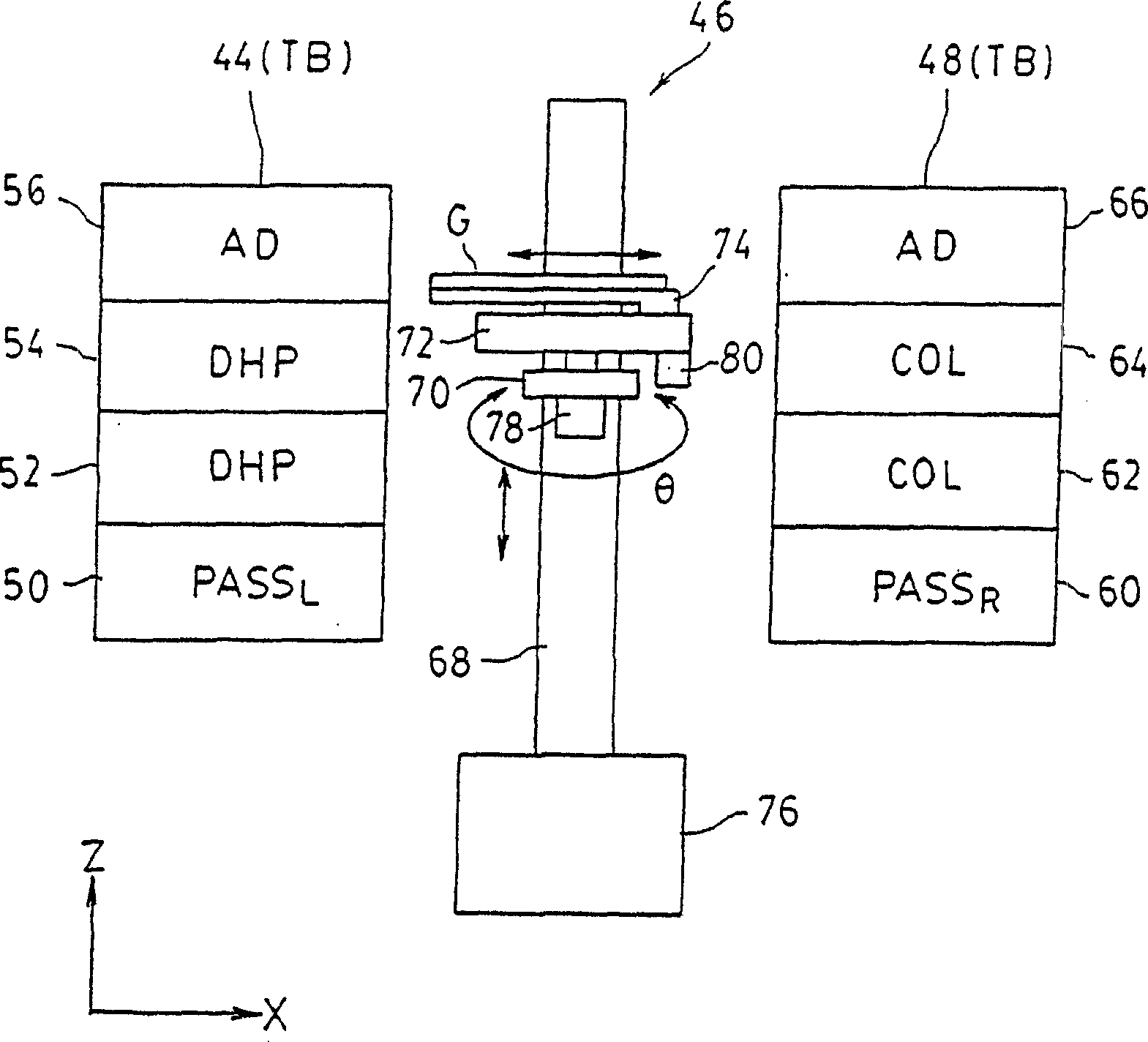

[0053] In this coating and development processing system 10, a horizontally long processing station (P / S) 16 is arranged at the central part, and a cartridge mounting station (C / S) 14 and an interface station are arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com