Apparatus and method for baking fluorescent lamp

A fluorescent lamp and equipment technology, applied in the application of luminescent paint, the manufacture of discharge tubes/lamps, parts of gas discharge lamps, etc., can solve the problems of bending and deformation of glass tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

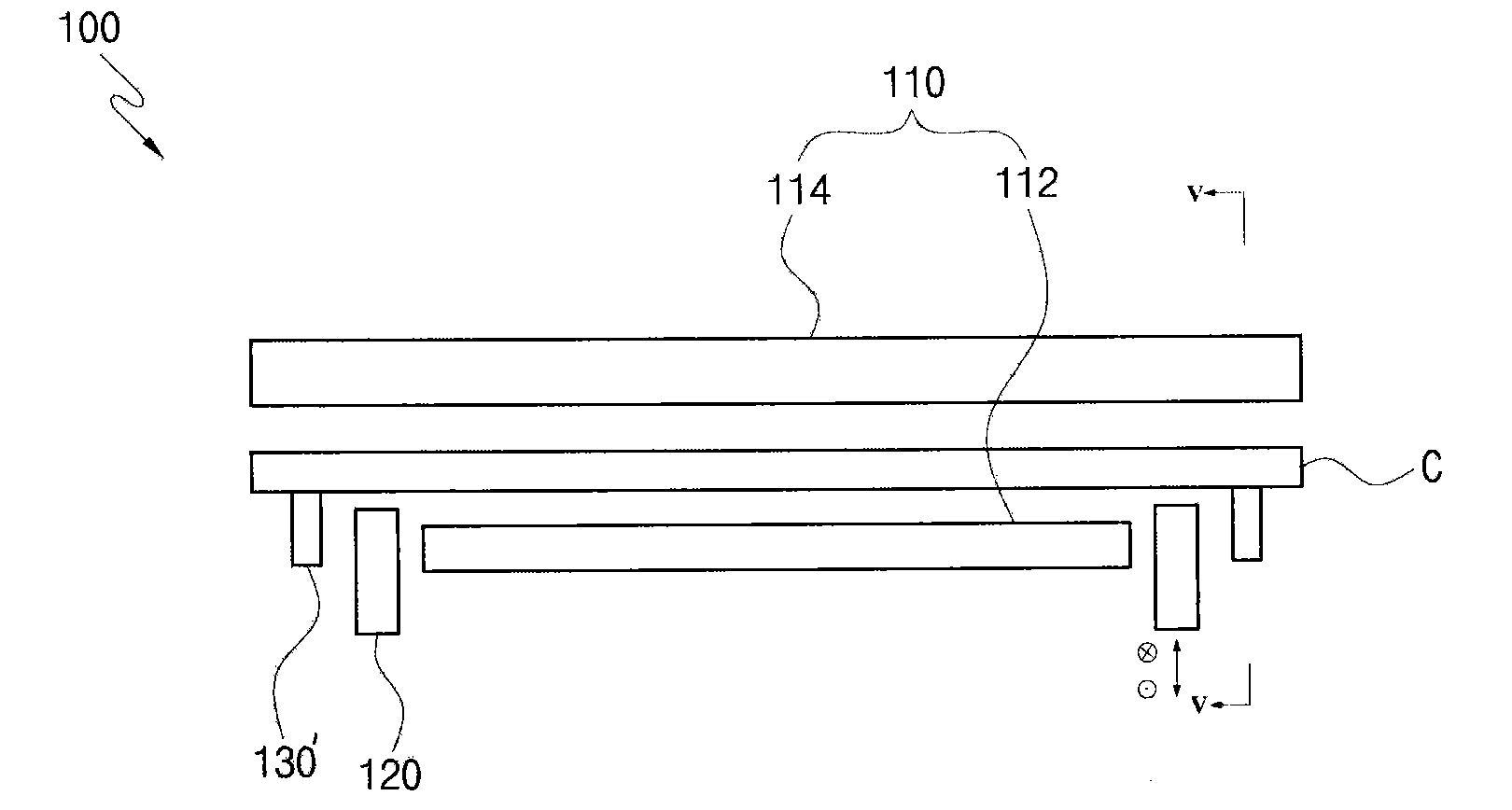

[0019] image 3 A device for baking fluorescent lamps according to an embodiment of the present invention is schematically shown. The fluorescent lamp baking equipment includes: a heater 110, a transfer block 120, and a rotating unit 130'. The heater 110 includes a lower heater 112 and an upper heater 114 . The heater 110 heats the quartz tube (C) from upward and downward directions. Such as Figure 4 As shown, the fluorescent lamp (L) is located inside the quartz tube (C).

[0020] Figure 5 supply image 3 A more detailed diagram along the V-V direction. The rotation unit 130' includes a plurality of rotation rollers 130 placed side by side in a space formed between the lower heater 112 and the upper heater 114. Referring to FIG. A plurality of quartz tubes C each having a fluorescent lamp L therein are placed on the upper portion of the rotating roller 130 . The lower heater 112 and the upper heater 114 heat the quartz tube passing therebetween, thereby baking the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com