Electronic component, production method therefor, and sealing material paste used therein

A technology for sealing materials and electronic parts, applied in the field of electronic parts, can solve the problems of slow penetration of water molecules, high bonding temperature, insufficient gas barrier properties, etc., and achieve the effect of reducing devitrification, reducing thermal damage, and effective manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] In this example, the composition and characteristics of the low-melting-point glass contained in the sealing material were studied. Examples are shown in Tables 1 to 4, and Comparative Examples are shown in Table 5. In the preparation of the low-melting point glasses shown in Table 1 to Table 5, reagent V manufactured by High Purity Chemical Research Laboratory was used. 2 o 5 , TeO 2 ,P 2 o 5 , Fe 2 o 3 、WO 3 、MoO 3 , Nb 2 o 5 、 Ta 2 o 5 , MnO 2 , Sb 2 o 3 、 Bi 2 o 3 , ZnO, SrCO 3 、BaCO 3 、Ag 2 O and K 2 CO 3as raw material. These raw materials were compounded and mixed in a specific amount to a total of 200 g, put into a platinum crucible, and heated to 900-1000°C in an electric furnace at a temperature increase rate of 5-10°C / min to melt. In order to form a uniform glass at this temperature, the raw materials were held for 2 hours while being stirred. Subsequently, the crucible is taken out, and the raw materials are flowed onto a stainless st...

Embodiment 2

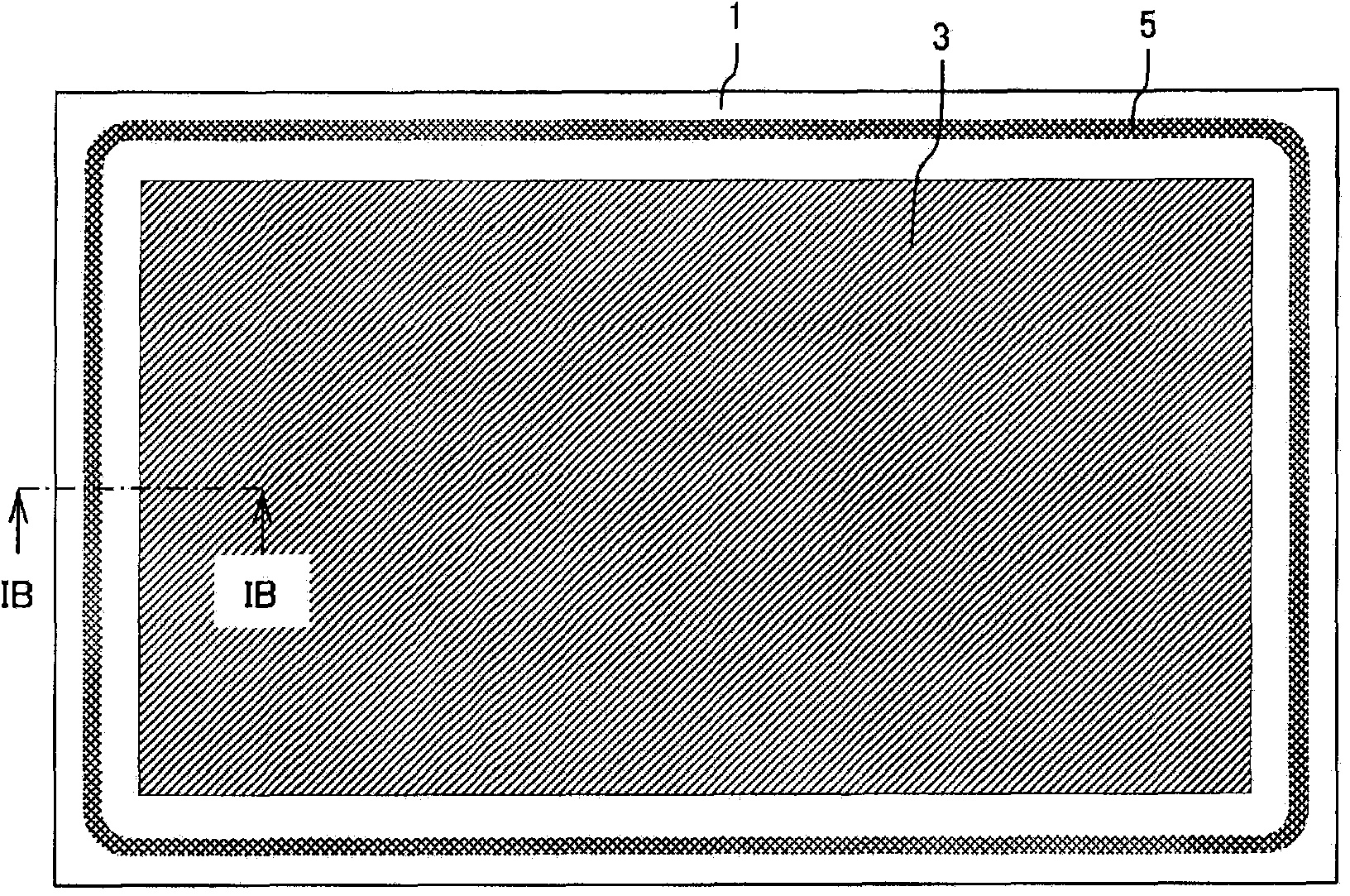

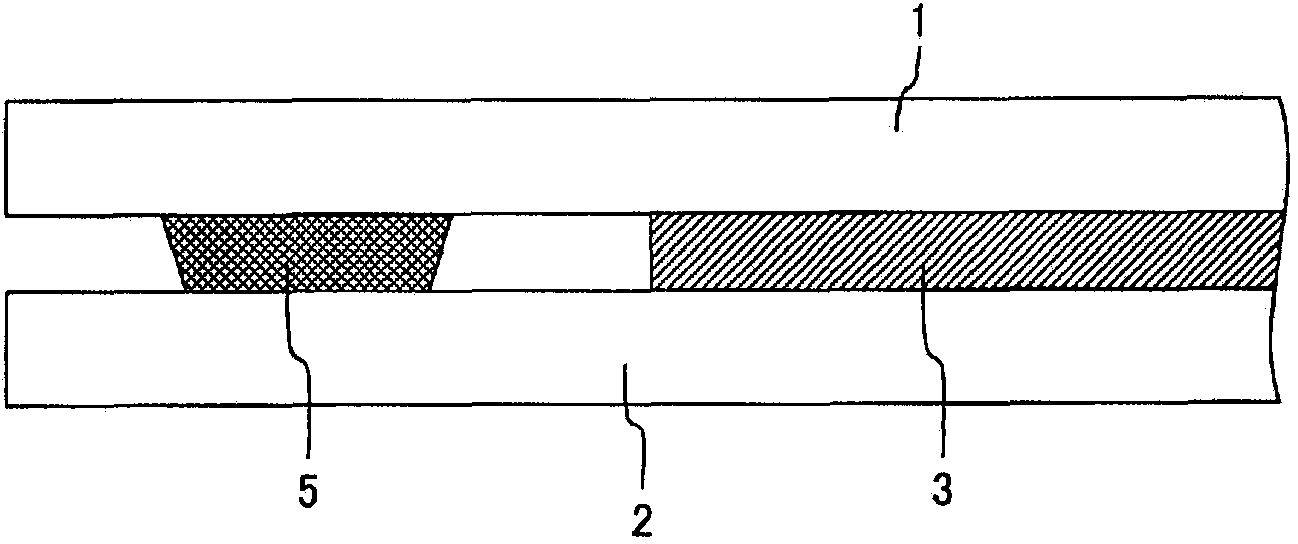

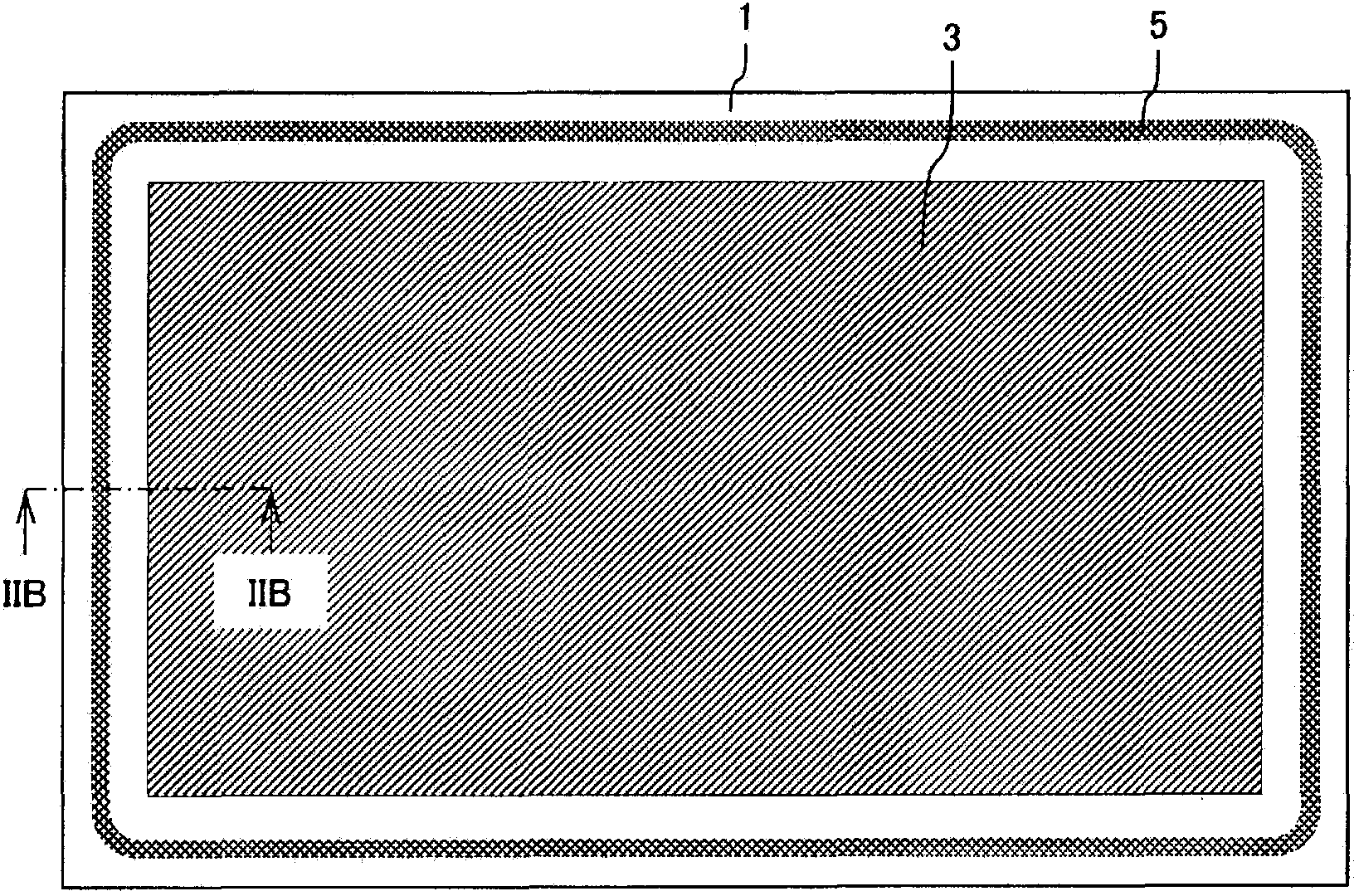

[0071] In this example, using the low-melting-point glass of Example G19 shown in Table 2 and a glass piece as a transparent substrate, a laser sealing experiment was performed. A sealing material paste was prepared using a jet mill to obtain G19 low-melting glass powder having an average particle diameter of 3 μm or less, a resin binder, and a solvent. Nitrocellulose was used as the resin binder, and butyl carbitol acetate was used as the solvent. Using this sealant paste, screen printing method such as Figure 11 As shown in , the sealing material paste was applied to the outer peripheral portion of the transparent substrate, and after drying, the sealing material paste was fired at 380° C. for 30 minutes in the air. The line width of the sealing material 5 formed on the transparent substrate 1 was 1.5 mm, and the fired film thickness thereof was adjusted by changing the coating amount to be about 5, 10, 20, and 30 μm, respectively. Such as Figure 12 As shown in , the tr...

Embodiment 3

[0077] In this embodiment, the transparent substrate uses 50×l0 -7 / °C coefficient of thermal expansion of the glass substrate. As the low-melting-point glass contained in the sealing material, Example G43 shown in Table 3 was used. Furthermore, zirconium phosphate tungstate (Zr 2 (WO 4 )(PO 4 ) 2 ), niobium oxide (Nb 2 o 5 ) and silicon (Si). Next, the same laser sealing experiment as in Example 2 was implemented.

[0078] First, G43 low-melting glass powder crushed with a jet mill to an average particle size of 3 μm or less, and Zr powder with an average particle size of about 5 μm 2 (WO 4 )(PO 4 ) 2 , Nb 2 o 5 Or Si filler particles, resin binder, and solvent to make sealing material paste. In addition, the content of the filler particles was set to 15, 25, 35, and 45 parts by volume with respect to 100 parts by volume of the low-melting glass of G43, respectively. The low melting point glass G43 used has a density of 3.53g / cm 3 , Zr 2 (WO 4 )(PO 4 ) 2 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com