Compound type liquid anti-freezing pumping agent and preparation method thereof

A pumping agent and composite technology, applied in the field of building materials, can solve problems such as environmental pollution, large amount of crystallization and precipitation, and loss of slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

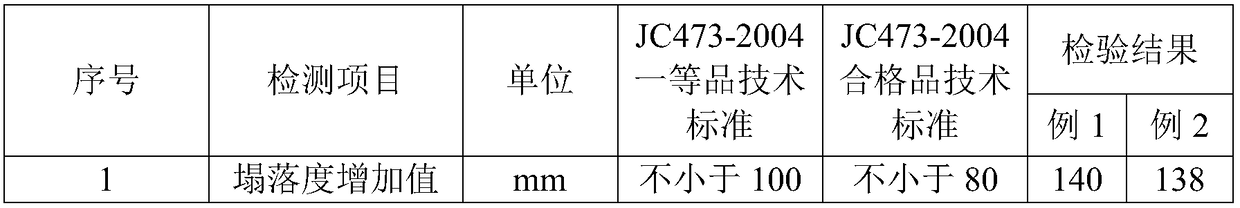

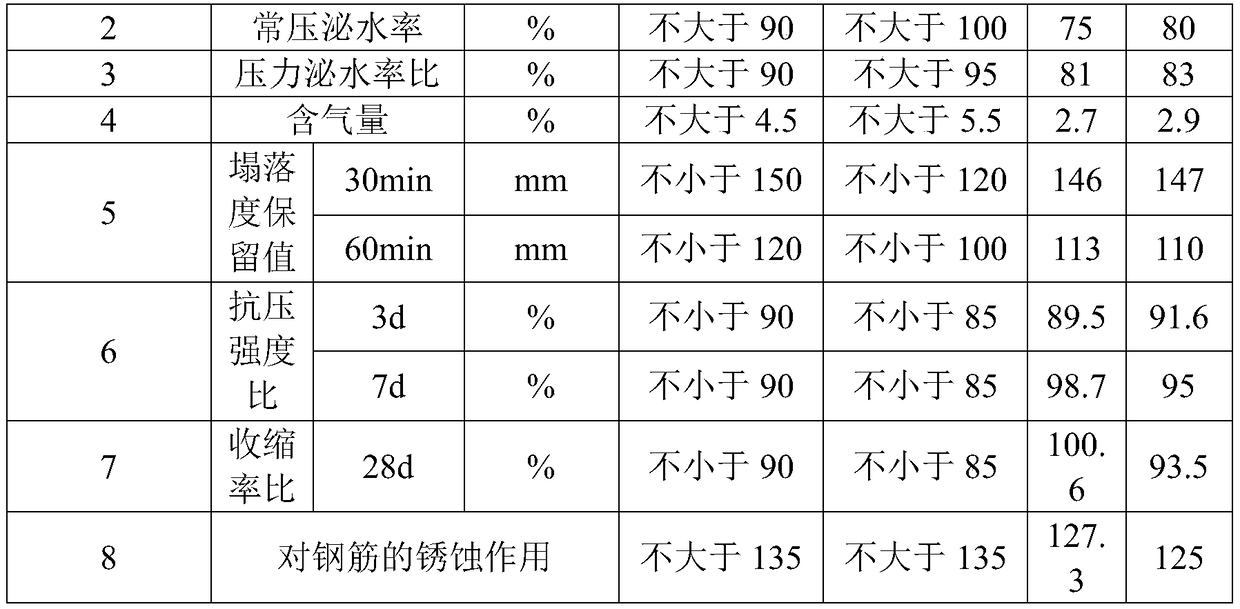

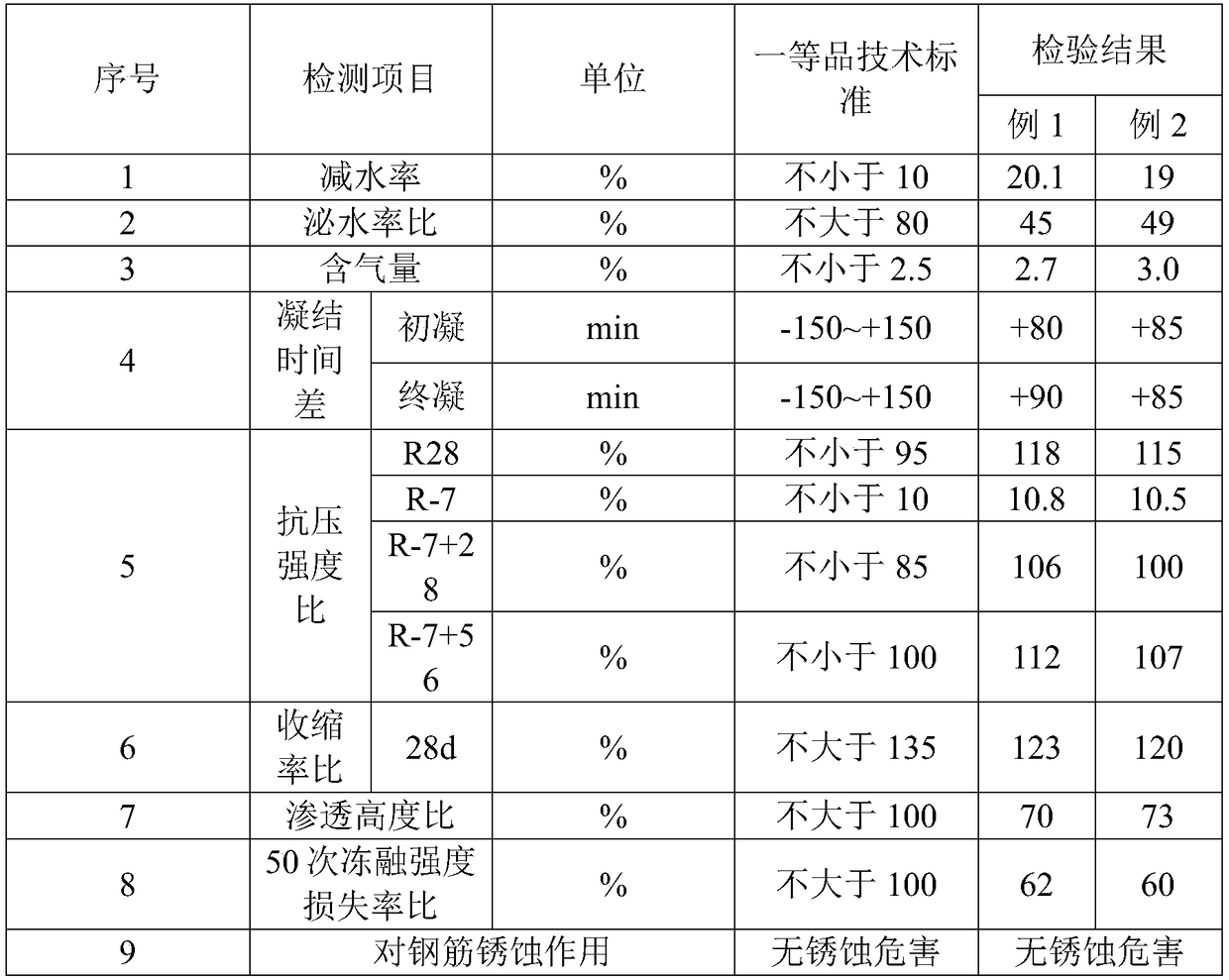

Examples

Embodiment 1

[0016] The composite liquid antifreeze pumping agent of the present invention consists of 32 parts by mass of polycarboxylate superplasticizer, 5 parts of alkylsuccinimide, and 2 parts of dioctyl phthalate. , 1.5 parts of sodium gluconate, 8 parts of magnesium acetate, 0.3 parts of sodium dodecylbenzenesulfonate, 1.3 parts of isopropanol, 1 part of brittle diatom antifreeze protein, 0.005 parts of polyethylene glycol Alcohol, 0.0025 parts of β-cyclodextrin, 0.0075 parts of dimethyl diallyl ammonium chloride and 48.9 parts of water.

[0017] The preparation method of the composite liquid antifreeze pumping agent of the present invention comprises the following steps: weighing polycarboxylate high-efficiency water reducer, alkyl succinimide, dioctyl phthalate, sodium gluconate, acetic acid Magnesium, sodium dodecylbenzene sulfonate, isopropanol, diatom brittle antifreeze protein, polyethylene glycol, β-cyclodextrin, dimethyldiallyl ammonium chloride and water, then water Add it...

Embodiment 2

[0019] The composite liquid antifreeze pumping agent of the present invention consists of 32 parts by mass of polycarboxylate superplasticizer, 6 parts of alkylsuccinimide, and 2.5 parts of dioctyl phthalate , 2 parts of sodium gluconate, 8 parts of magnesium acetate, 0.4 parts of sodium dodecylbenzenesulfonate, 1.5 parts of isopropanol, 1.5 parts of brittle diatom antifreeze protein, 0.007 parts of polyethylene glycol alcohol, 0.003 parts of β-cyclodextrin, 0.008 parts of dimethyl diallyl ammonium chloride and 46 parts of water.

[0020] The preparation method of the composite liquid antifreeze pumping agent of the present invention comprises the following steps: weighing polycarboxylate high-efficiency water reducer, alkyl succinimide, dioctyl phthalate, sodium gluconate, acetic acid Magnesium, sodium dodecylbenzene sulfonate, isopropanol, diatom brittle antifreeze protein, polyethylene glycol, β-cyclodextrin, dimethyldiallyl ammonium chloride and water, then water Add it t...

Embodiment 3

[0022] The composite liquid antifreeze pumping agent of the present invention consists of 30 parts by mass of polycarboxylate superplasticizer, 6 parts of alkylsuccinimide, and 2 parts of dioctyl phthalate. , 2 parts of sodium gluconate, 8 parts of magnesium acetate, 0.4 parts of sodium dodecylbenzenesulfonate, 1.5 parts of isopropanol, 1 part of brittle diatom antifreeze protein, 0.007 parts of polyethylene glycol alcohol, 0.0025 parts of β-cyclodextrin, 0.008 parts of dimethyl diallyl ammonium chloride and 45 parts of water.

[0023] The preparation method of the composite liquid antifreeze pumping agent of the present invention comprises the following steps: weighing polycarboxylate high-efficiency water reducer, alkyl succinimide, dioctyl phthalate, sodium gluconate, acetic acid Magnesium, sodium dodecylbenzene sulfonate, isopropanol, diatom brittle antifreeze protein, polyethylene glycol, β-cyclodextrin, dimethyldiallyl ammonium chloride and water, then water Add it to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com