A kind of preparation method of low-temperature curable high-imino high-etherified melamine resin

A high-etherified melamine and melamine technology, which is applied in the field of melamine resin preparation, can solve the problems of increased temperature, reduced imino content, and high product viscosity, and achieves increased hydroxyl value, low baking temperature, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Put 90g of melamine and 30% formaldehyde solution into a four-necked flask according to the molar ratio of melamine: formaldehyde of 1:4.5, stir and adjust pH=9 with 10% NaOH and heat up to 50°C, after the melamine is completely dissolved keep warm for 2 hours;

[0026] (2) Then the system is cooled to below 35°C, methanol is added, and methanol is added according to the ratio of melamine: the molar ratio of methanol is 1:20, and the mixed solution with 37% hydrochloric acid: 88% formic acid volume ratio is 2: 1 to adjust the pH = 5. Keep warm for 2 hours after being transparent;

[0027] (3) After the etherification is finished, use 30% NaOH to adjust pH=9, carry out vacuum distillation at 80°C, finish distillation when the pressure is less than or equal to 1.0KPa after about 2 hours, add isobutanol to adjust product viscosity, and then Add 4% diatomaceous earth, stir evenly, and then suction filter until transparent.

Embodiment 2

[0029] (1) Put 90g of melamine and 30% formaldehyde solution into a four-neck flask according to the molar ratio of melamine:formaldehyde of 1:4.5, stir and adjust the pH to 9 with 10% NaOH; heat up to 55°C until the melamine is completely dissolved Keep warm for 90 minutes;

[0030] (2) Then cool down to below 35°C, add methanol, add methanol according to the ratio of melamine:methanol molar ratio of 1:20, adjust pH=4 with 37% hydrochloric acid: 88% formic acid mixed solution with a volume ratio of 3:1 , keep warm for 90 minutes after being transparent;

[0031] (3) After the etherification is finished, use 30% NaOH to adjust pH=9, carry out vacuum distillation at 80°C, finish distillation when the pressure is less than or equal to 1.0KPa after about 2 hours, add isobutanol to adjust product viscosity, and then Add 4% diatomaceous earth, stir evenly, and then suction filter until transparent.

Embodiment 3

[0033] (1) Put 90g of melamine and 30% formaldehyde solution into a four-necked flask according to the molar ratio of melamine: formaldehyde of 1:4.5, stir and adjust the pH to 9 with 10% NaOH; heat up to 45°C until the melamine is completely dissolved Keep warm for 3 hours;

[0034] (2) Then add methanol at 30°C, methanol is added according to the ratio of melamine:methanol molar ratio of 1:20, and the mixed solution with 37% hydrochloric acid:88% formic acid volume ratio of 1:3 is used to adjust pH=3 , keep warm for 45 minutes after being transparent;

[0035] (3) After the etherification is finished, use 30% NaOH to adjust pH=9, carry out vacuum distillation at 80°C, finish distillation when the pressure is less than or equal to 1.0KPa after about 2 hours, add isobutanol to adjust product viscosity, and then Add 4% diatomaceous earth, stir evenly, and then suction filter until transparent.

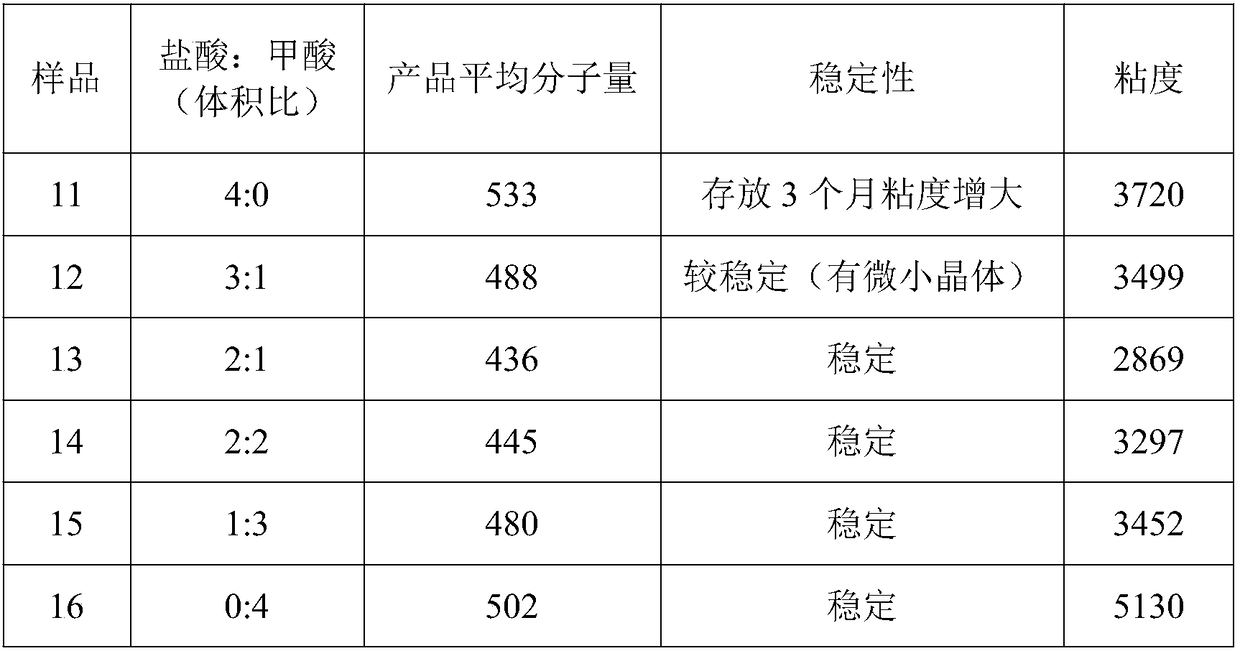

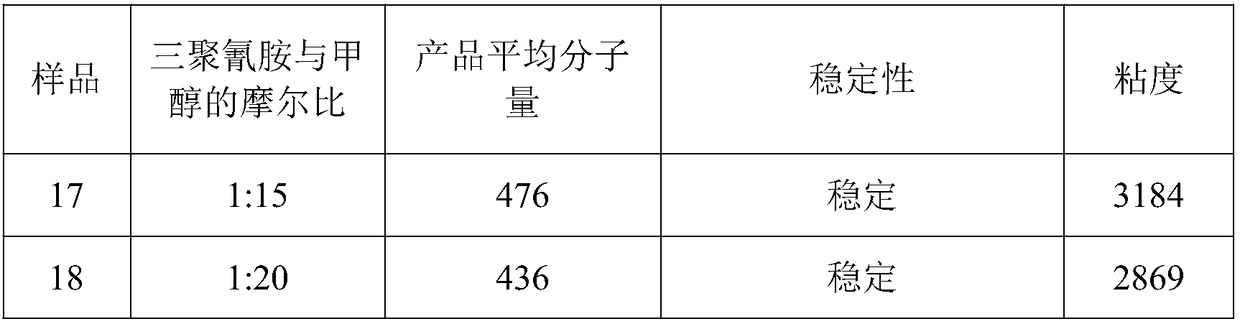

[0036] 2. Experimental results

[0037] 2.1 Determination results of formaldehyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com