Non-water treatment agent used for surface enhanced treatment of fluorozirconate glass optical fiberpreform rod and treatment method

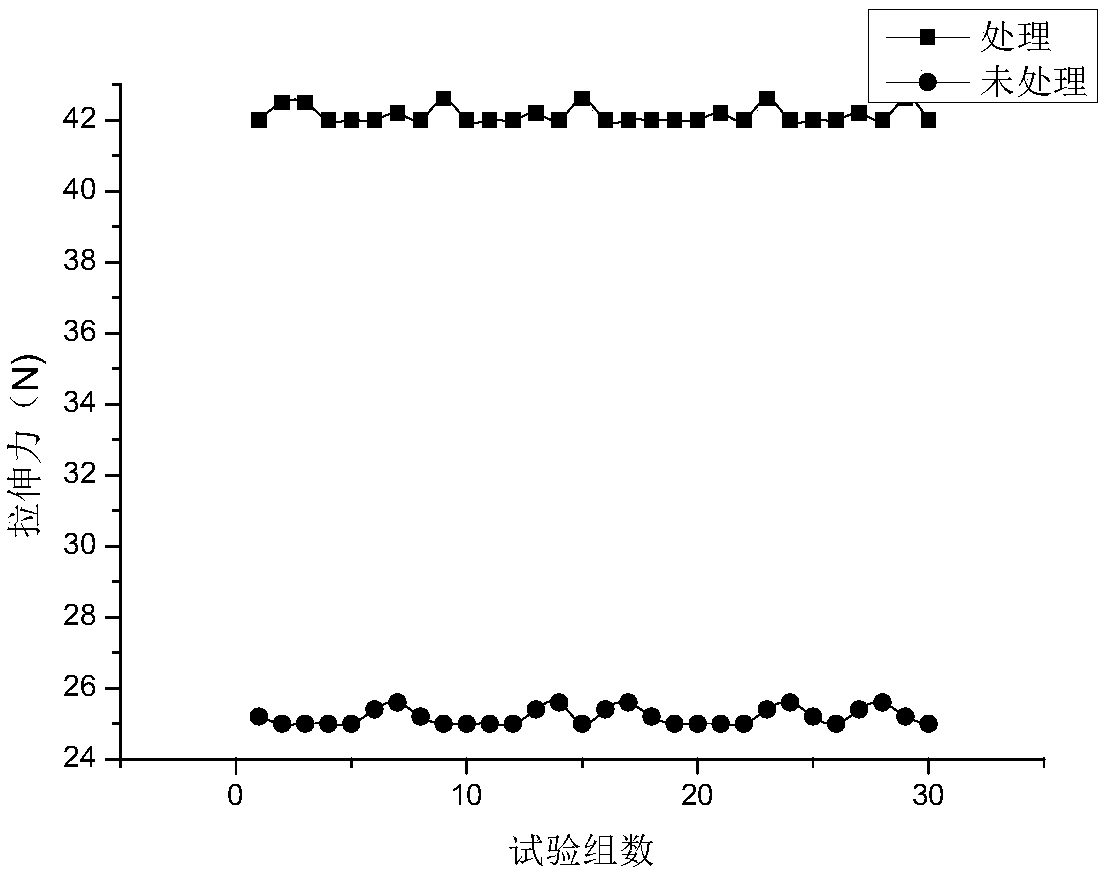

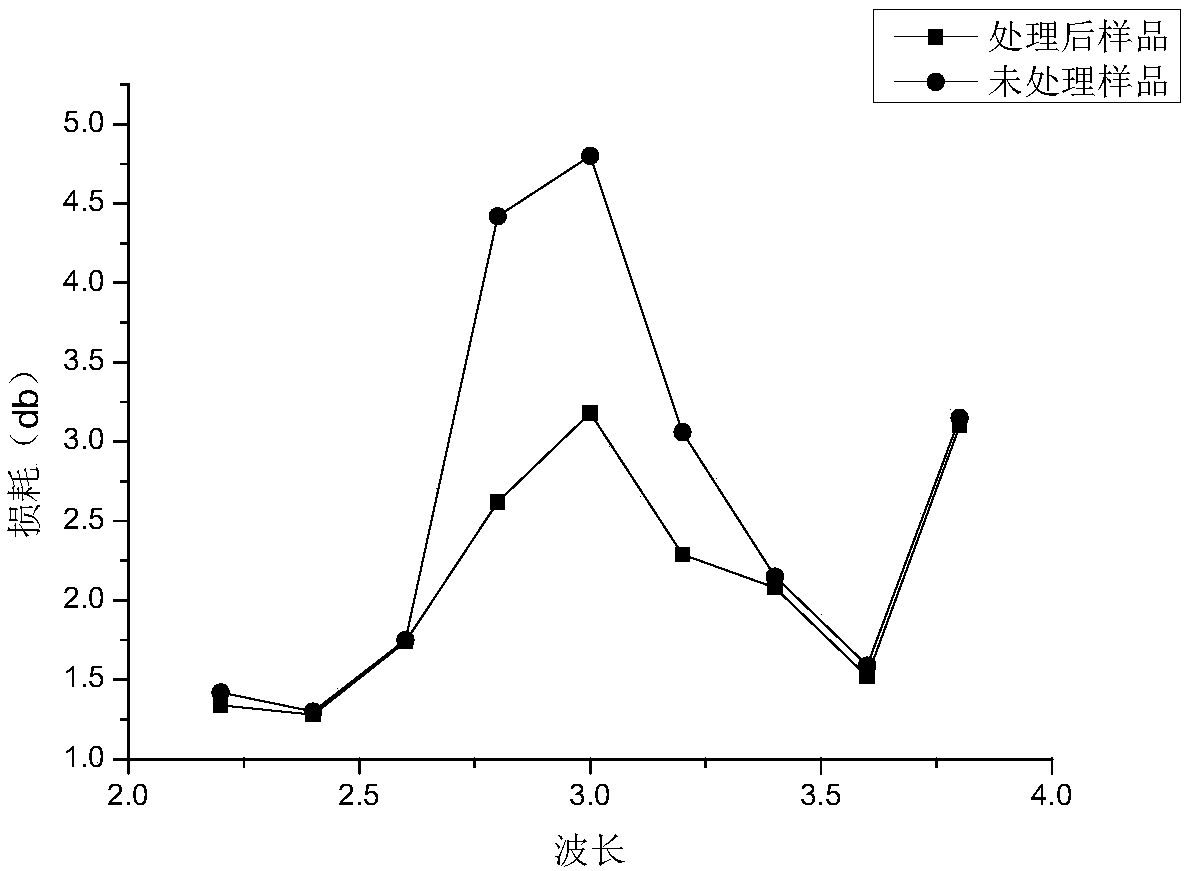

A non-aqueous treatment, fluorozirconate technology, used in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of being easily eroded by water molecules, high fiber interface loss, crystallization, etc., and reduce crystallization or devitrification. Risk, increase the mechanical strength of the fiber, the effect of uniform chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0043] The non-water treatment agent is composed of an acid part, a zirconium salt part and an organic solvent part in a molar ratio of 2:3:50, and the components and molar percentages of each part are:

[0044] 1) Acid part:

[0045]

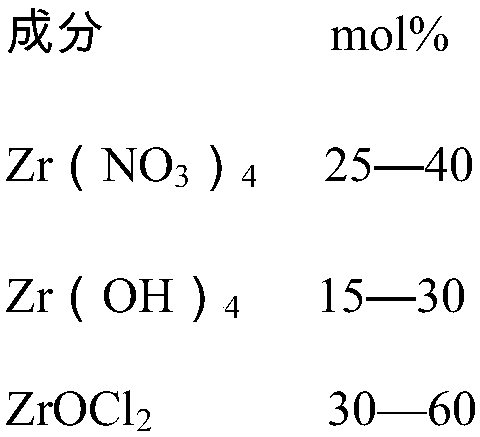

[0046] 2) Zirconium salt part:

[0047]

[0048] 3) Organic solvent part:

[0049]

[0050] A treatment method for performing surface enhancement treatment on a fluorozirconate glass optical fiber preform, comprising the following steps:

[0051] Step 1: Put the fluorozirconate glass optical fiber preform sample into a polytetrafluoroethylene box, add high-purity ethanol to submerge it, and then put the box into an ultrasonic cleaning machine for ultrasonic cleaning at 25°C for 20 minutes.

[0052] Step 2: Take out the box after ultrasonic cleaning, pour out the high-purity ethanol, and then pour the non-aqueous treatment agent prepared according to the above ratio to submerge the sample.

[0053] Step 3: Put the box into the ultras...

no. 2 example

[0058] The non-water treatment agent is composed of an acid part, a zirconium salt part and an organic solvent part in a molar ratio of 2:3:60, and the components and molar percentages of each part are:

[0059] 1) Acid part:

[0060]

[0061] 2) Zirconium salt part:

[0062]

[0063] 3) Organic solvent part:

[0064]

[0065] A treatment method for performing surface enhancement treatment on a fluorozirconate glass optical fiber preform, comprising the following steps:

[0066] Step 1: Put the fluorozirconate glass optical fiber preform sample into a stainless steel box, add high-purity ethanol to submerge it, and then put the box into an ultrasonic cleaning machine for ultrasonic cleaning at 25°C for 20 minutes.

[0067] Step 2: Take out the box after ultrasonic cleaning, pour out the high-purity ethanol, and then pour the non-aqueous treatment agent prepared according to the above ratio to submerge the sample.

[0068] Step 3: Put the box into the ultrasonic cle...

no. 3 example

[0073] The non-water treatment agent is composed of an acid part, a zirconium salt part and an organic solvent part in a molar ratio of 2:3:70, and the components and molar percentages of each part are:

[0074] 1) Acid part:

[0075]

[0076] 2) Zirconium salt part:

[0077]

[0078]

[0079] 3) Organic solvent part:

[0080]

[0081] A treatment method for performing surface enhancement treatment on a fluorozirconate glass optical fiber preform, comprising the following steps:

[0082] Step 1: Put the fluorozirconate glass optical fiber preform sample into a polytetrafluoroethylene box, add high-purity ethanol to submerge it, and then put the box into an ultrasonic cleaning machine for ultrasonic cleaning at 25°C for 20 minutes.

[0083] Step 2: Take out the box after ultrasonic cleaning, pour out the high-purity ethanol, and then pour the non-aqueous treatment agent prepared according to the above ratio to submerge the sample.

[0084] Step 3: Put the box int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com