Low-dielectric sealing glass granulation powder and preparation method thereof

A technology for sealing glass and granulating powder, which is used in glass manufacturing equipment, glass molding, manufacturing tools, etc. completely and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] 1) Weigh the raw material SiO according to the glass ratio 2 : 68.2~72.3%, H 3 BO 3 :41.4~24.8%, Al 2 o 3 :1~2%,Na 2 CO 3 :2~3%, K 2 CO 3 :0.5~1%, CaCO 3 :0.5~1%, Bi 2 o 3 : 0.5~1%, the raw materials are placed in a V-shaped mixer and mixed for 30 minutes;

[0027] 2) The uniformly mixed raw materials are kept at 1600°C for 100 minutes for high-temperature melting, and part of the molten glass is made into glass discs and glass rods, and part of it is quenched in water to obtain glass slag;

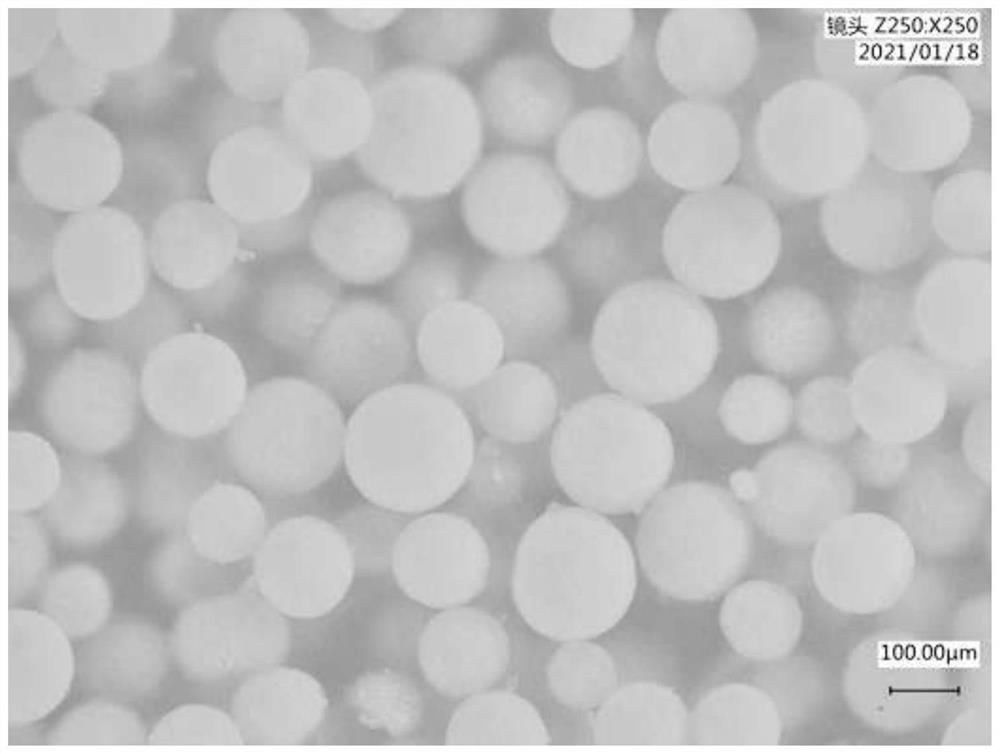

[0028] 3) Grinding the glass slag in the planetary ball mill, adding grinding balls according to the material-ball ratio of 1:0.8, and the ball milling time is 120min. The ground glass powder is sieved, and the glass powder under the 150 mesh sieve is taken for subsequent use;

[0029] 4) Disperse the glass powder under the 150-mesh sieve in the liquid phase composed of solvent and binder, add mixing balls, and mill for 100 minutes to obtain glass powder slurry, glass p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com