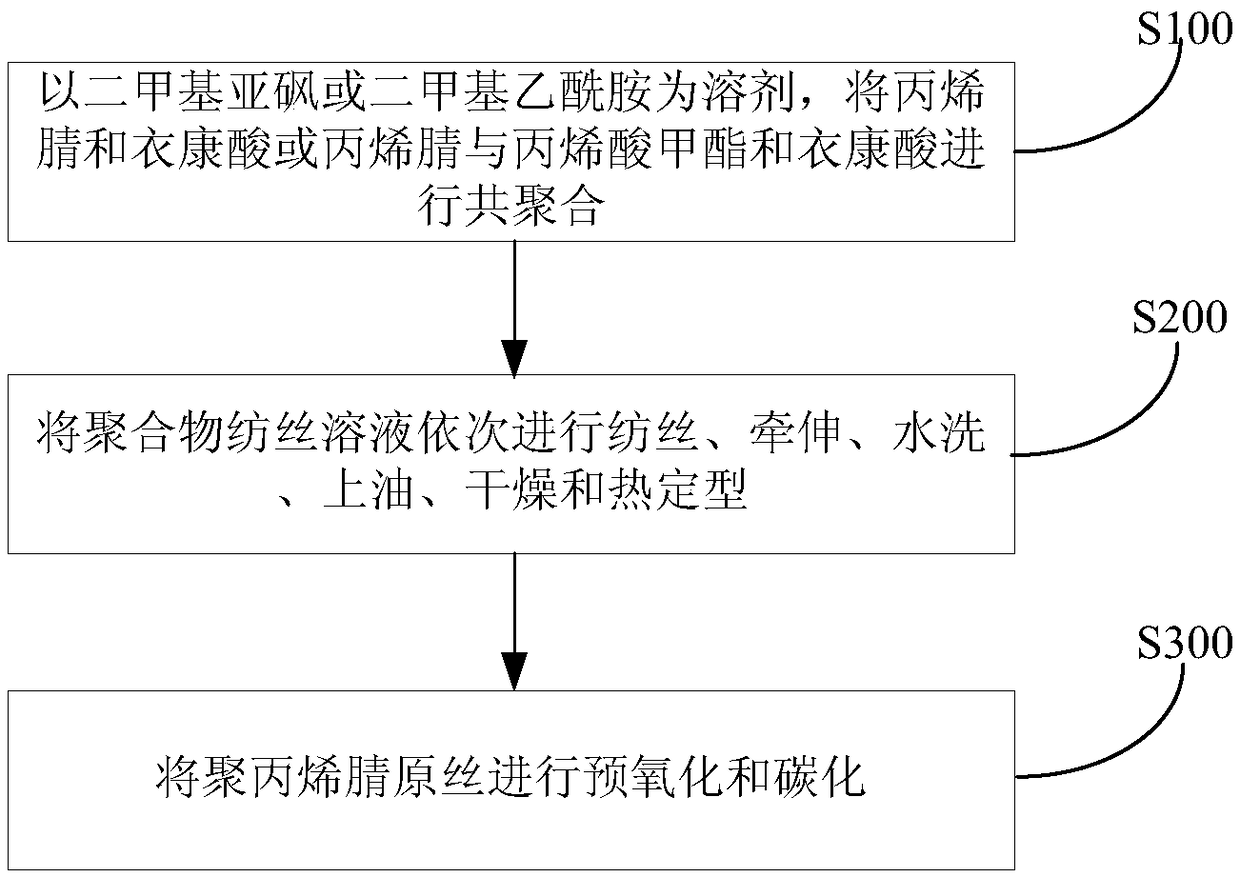

Ultra-high strength and middle high-modulus polyacrylonitrile carbon fibers as well as preparation method thereof

A polyacrylonitrile carbon fiber, ultra-high-strength technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems affecting the strength and modulus of carbon fibers, devitrification of PAN strands, and decline in the performance of raw silk, and achieve compactness. High, reduce devitrification, improve the effect of fiber uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

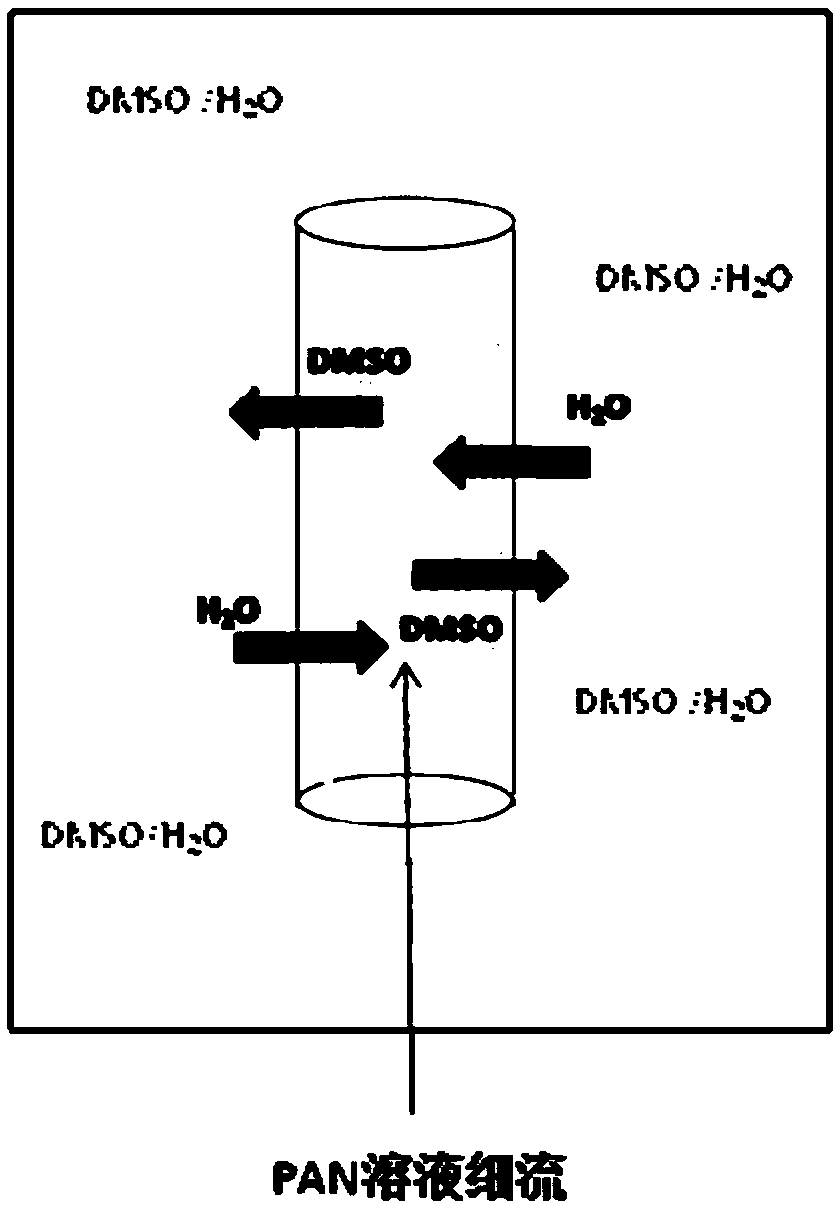

[0040] Using azobisisobutyronitrile (AIBN) as an initiator and dimethyl sulfoxide (DMSO) as a solvent, acrylonitrile solution copolymerization is carried out. On the basis of the total mass of comonomers dropped in, acrylonitrile monomers and comonomers methyl acrylate and itaconic acid were dropped into the polymerization kettle at the ratio of 97.2% acrylonitrile, 1.6% methyl acrylate and 1.2% itaconic acid, Then add the solvent DMSO, control the monomeric acrylonitrile to account for 22% of the total mass of the polymerization system, react at a temperature of 65° C. for 24 hours, and perform wet spinning on the obtained polymerization solution after single removal and defoaming. The spinning solution passes through a metering pump, a candle filter, and a spinneret (the number of holes in the spinneret is 1000, and the hole diameter is 0.055mm), and then enters the first-stage coagulation bath system (20°C) composed of glycerol, and the propane In the secondary coagulation ...

Embodiment 2

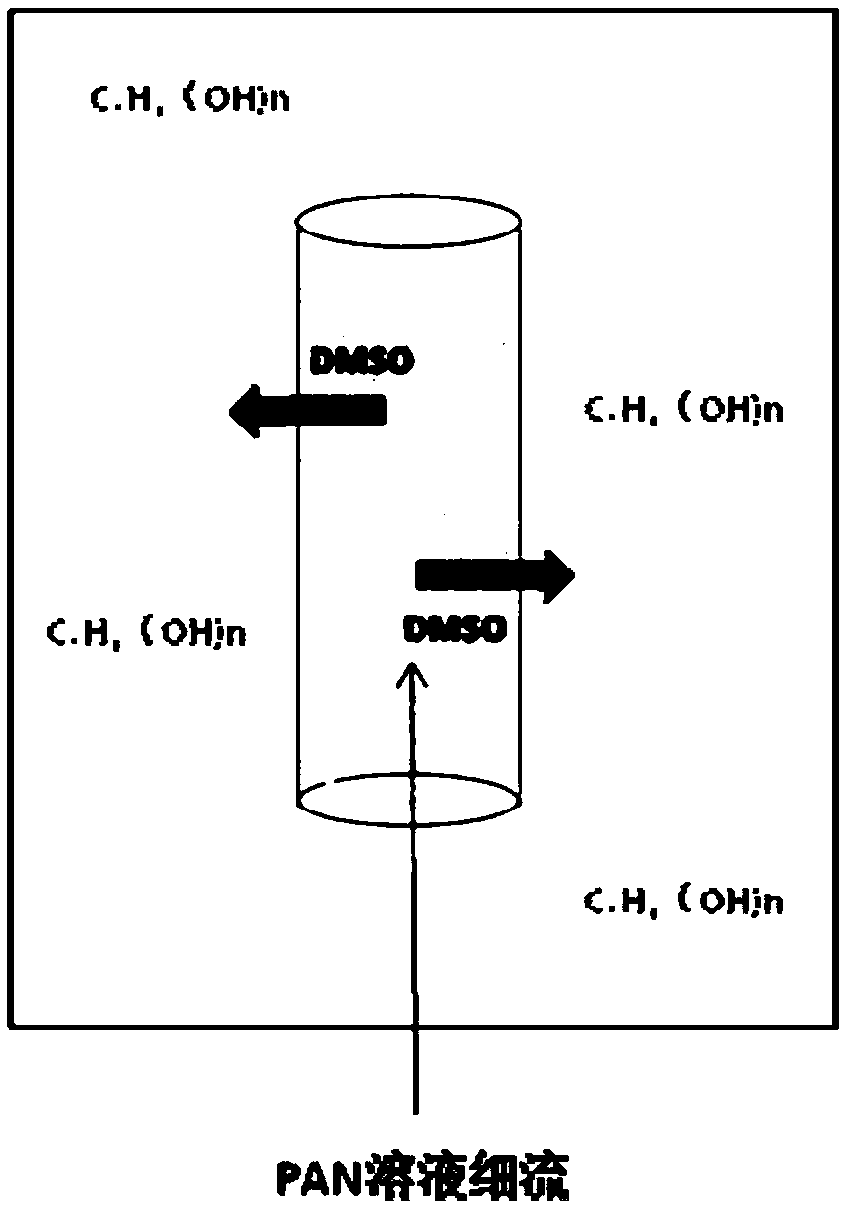

[0042] According to the polymerization formula of Example 1, the materials were fed into the polymerization kettle, and the polymerization reaction, single removal and defoaming were carried out under the same process conditions. The spinning solution passes through a metering pump, a candle filter, and a spinneret (the aperture of the spinneret is 0.06 mm, and the pump supply is increased to make the spinning speed the same), and in a primary coagulation bath system composed of glycerol (40 ° C ) and a secondary coagulation bath system (40°C) composed of diethylene glycol, gradient gelation into fibers into nascent fibers, pre-drawing 5 times in boiling water, washing with water, drying with oiled hot rollers, and then passing through superheated steam Re-drawing 2.9, the secondary total drafting is controlled at 14.5 times, and the polyacrylonitrile precursor is obtained through heat setting. The fineness of the raw silk produced is 86tex, and the bulk density is 1.19g / cm 3...

Embodiment 3

[0044] Polymerization, single removal, and defoaming were performed according to Example 1. The spinning solution passes through a metering pump, a candle filter, and a spinneret (the aperture of the spinneret is 0.055 mm), and then enters a coagulation bath system composed of glycerol and diethylene glycol, wherein the mass of glycerol The concentration is 65% (the mass concentration of diethylene glycol is 35%), the temperature is 40° C., and the PAN precursor is prepared through the same subsequent spinning process as in Example 1. The fineness of the raw silk produced is 86tex, and the bulk density is 1.191g / cm 3, the raw silk is pre-oxidized in an air atmosphere at 200-260°C, treated in a low-temperature carbonization furnace with three temperature zones consisting of 350, 450 and 800°C in a nitrogen atmosphere, and treated in a high-temperature carbonization furnace at 1300 and 1800°C in a nitrogen atmosphere , the tensile strength of carbon fiber bundles is 5610MPa, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com