Improved near-infrared filter glass

A near-infrared and filter glass technology, applied in the field of improved near-infrared filter glass, can solve the problems of glass brittleness, limitation, weather resistance and sintering temperature affecting transmittance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to understand the technical features and practical effects of the present invention, and implement it according to the contents of the description, the preferred embodiment shown in the drawings will be described in detail below.

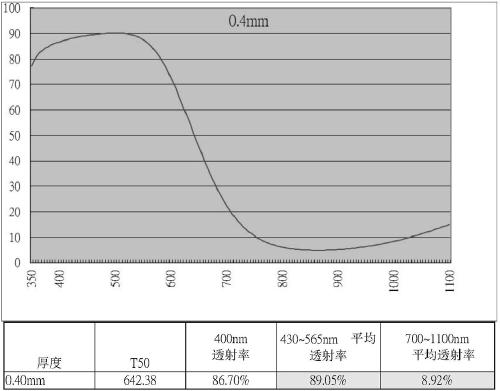

[0032] see figure 1 , the composition of the improved near-infrared filter glass of the present invention is based on Al(PO 3 ) 3 and P 2 o 5 The main material contains 35% to 45% Al(PO 3 ) 3 , 10% to 20% of P 2 o 5 And 3% to 7% of SrO and 6% to 15% of CuO; and can add 15%2 O+Na 2 O+Mgo+ZnO>20% composition, resulting in a lower melting temperature. The above "%" is mole percentage, and "%" below means the same meaning.

[0033] The near-infrared light-absorbing glass substrate of the present invention is formed by melting the raw material composition at a temperature of 1150° C. and cooling the melted composition.

[0034] Al(PO 3 ) 3 Is the essential ingredient of the present invention, because using Al(PO 3 ) 3 than Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com