Low expansion coefficient micro crystal glass and its heat processing method

A low-expansion-coefficient, glass-ceramics technology, applied in the field of low-expansion-coefficient glass-ceramics, can solve problems such as difficult heat treatment of bulk materials, and achieve the effects of easy forming and low crystallization tendency

Active Publication Date: 2011-02-02

CDGM OPTICAL GLASS

View PDF2 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The existing heat treatment method for glass-ceramics with low expansion coefficient is mainly a two-step method. This method is mainly aimed at thin plates or small pieces of glass that require rapid heat treatment, and it is difficult to heat treat bulk materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

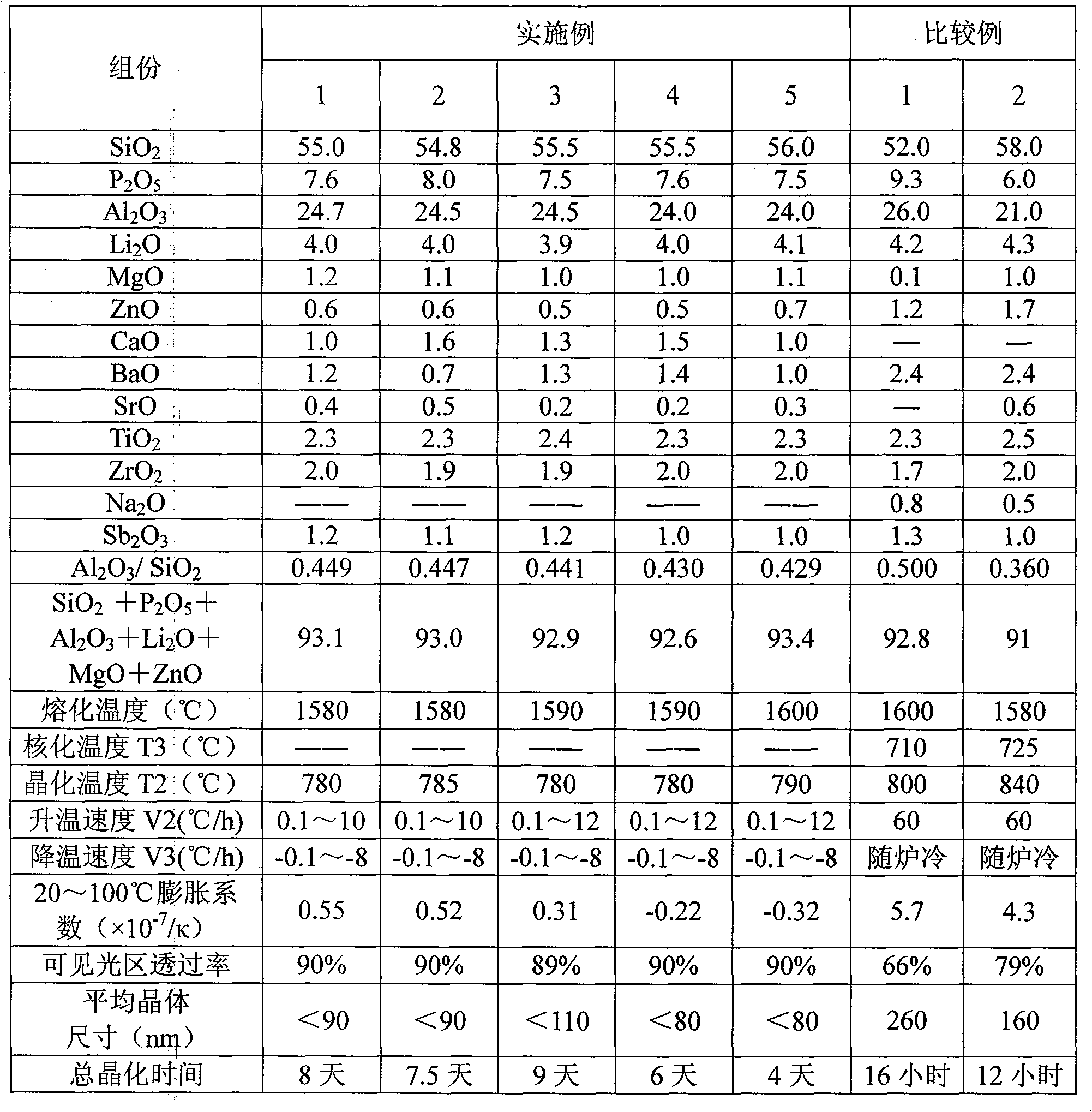

[0031] Table 1 is 5 embodiments of the present invention and 2 comparative examples, 5 embodiments of the present invention adopt the method of the present invention to carry out heat treatment, 2 comparative examples adopt existing method to carry out heat treatment.

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

Login to View More

Abstract

The present invention provides one kind of low expansion coefficient micro crystalline glass comprising SiO2 51.5-64 wt%, P2O5 6.8-11 wt%, Li2O 3-5.2 wt%, MgO 0.5-2.2 wt%, ZnO 0.4-2.1 wt%, CaO 0.2-2.5 wt%, BaO 0.5-4.5 wt%, SrO 0.2-3 wt%, and Sb2O3 0.6-2 wt%, Al2O3+SiO2 75-84 wt%, and TiO2+ZrO2 3.5-5 wt%. The micro crystalline glass has expansion coefficient at 20-100 deg.C of + / -0.6x10<-7> / K, visible light transmittance up to 90 %, low recrystallization trend and easy formation.

Description

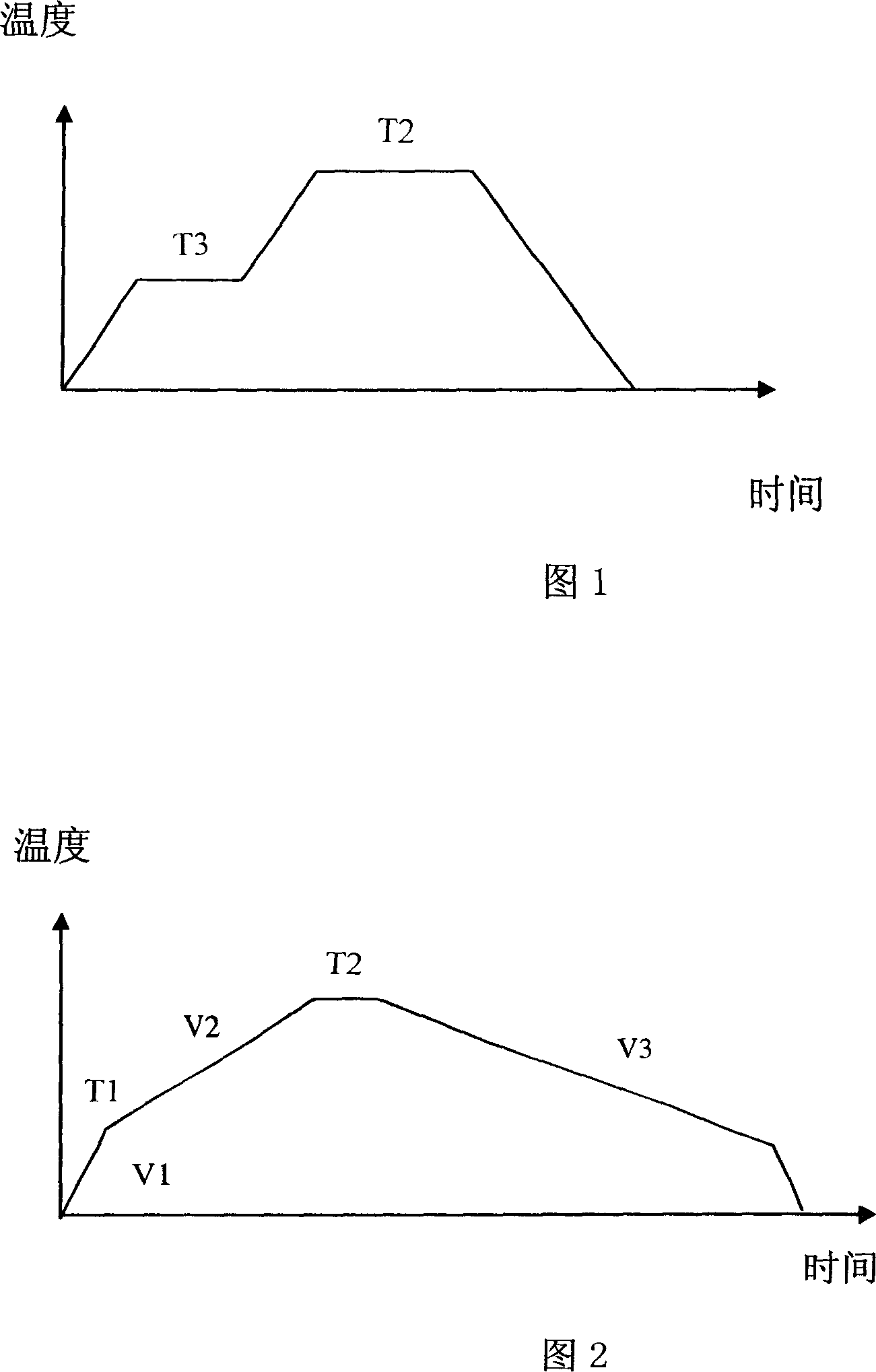

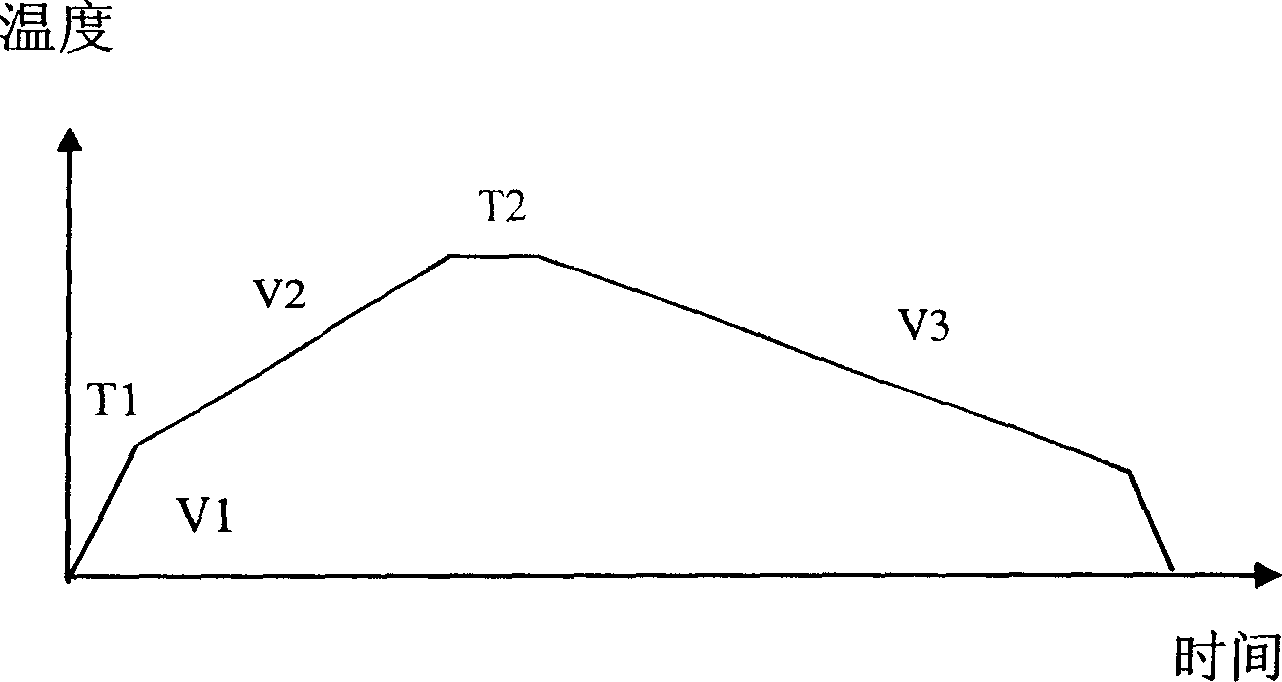

technical field [0001] The present invention relates to a kind of glass ceramics with low expansion coefficient, particularly relate to a kind of Li 2 O-Al 2 o 3 -SiO 2 Systematic low-expansion-coefficient glass-ceramic and its heat treatment method. Background technique [0002] Japanese Patent Laid-Open No. 2005-89272 and Japanese Patent Laid-Open No. 2005-231994 disclose two kinds of low-expansion coefficient glass-ceramics. The chemical composition of these two technical solutions does not contain SrO, and its crystallization tendency and forming difficulty are not clear. [0003] The existing heat treatment method for glass-ceramics with low expansion coefficient is mainly a two-step method. This method is mainly aimed at thin plates or small pieces of glass that require rapid heat treatment, and it is difficult to heat treat bulk materials. Contents of the invention [0004] The technical problem to be solved by the present invention is to provide a glass-ceramic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C03C3/097C03C10/14C03B32/02

CPCC03C3/097C03C10/00

Inventor 孙伟李启甲黄刚

Owner CDGM OPTICAL GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com