Hydraulic upward turnover type gate

A flip-up, gate technology, applied in water conservancy engineering, marine engineering, coastline protection, etc., can solve the problems of low degree of automation, complex structure, poor landscape effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

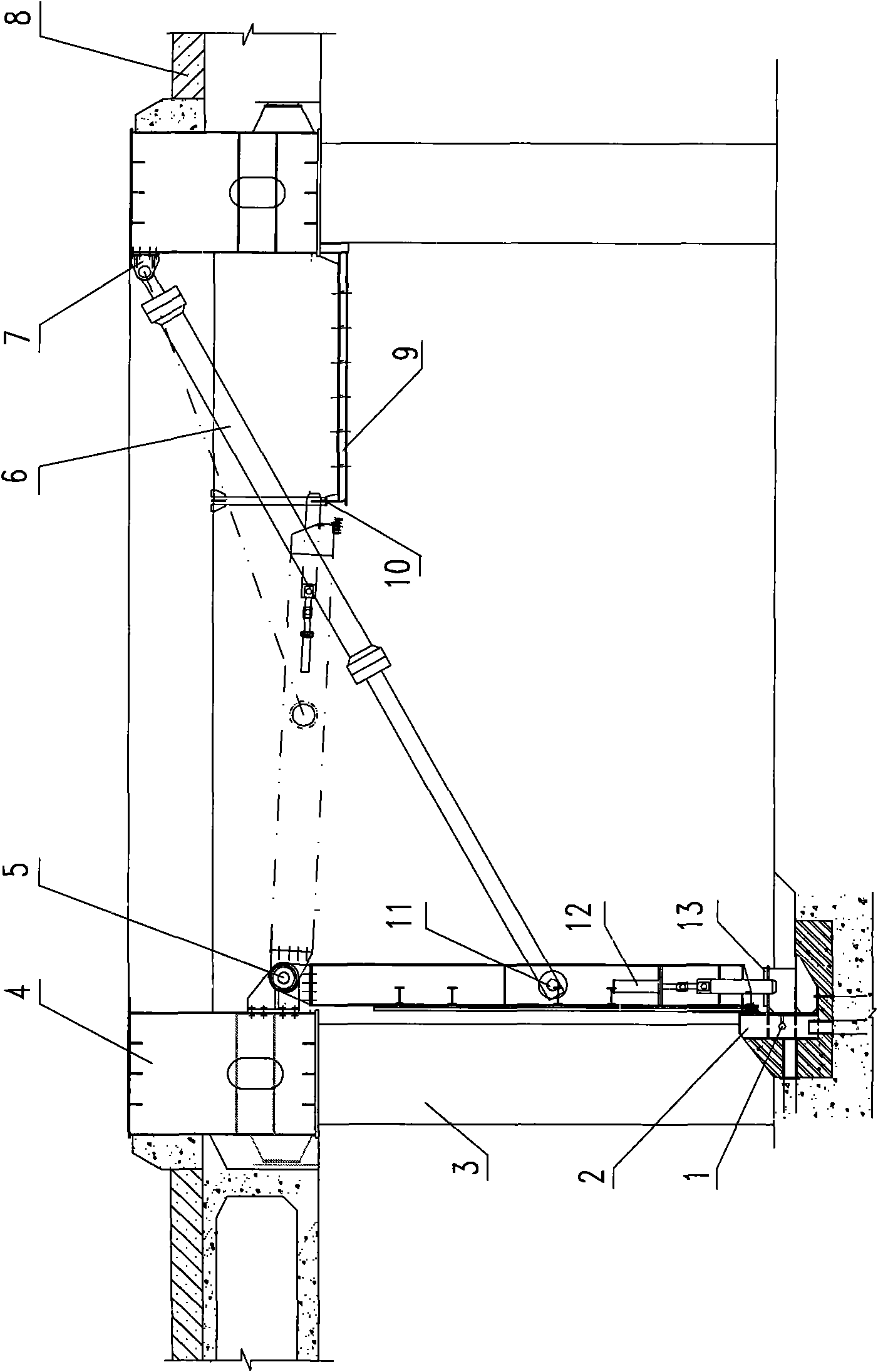

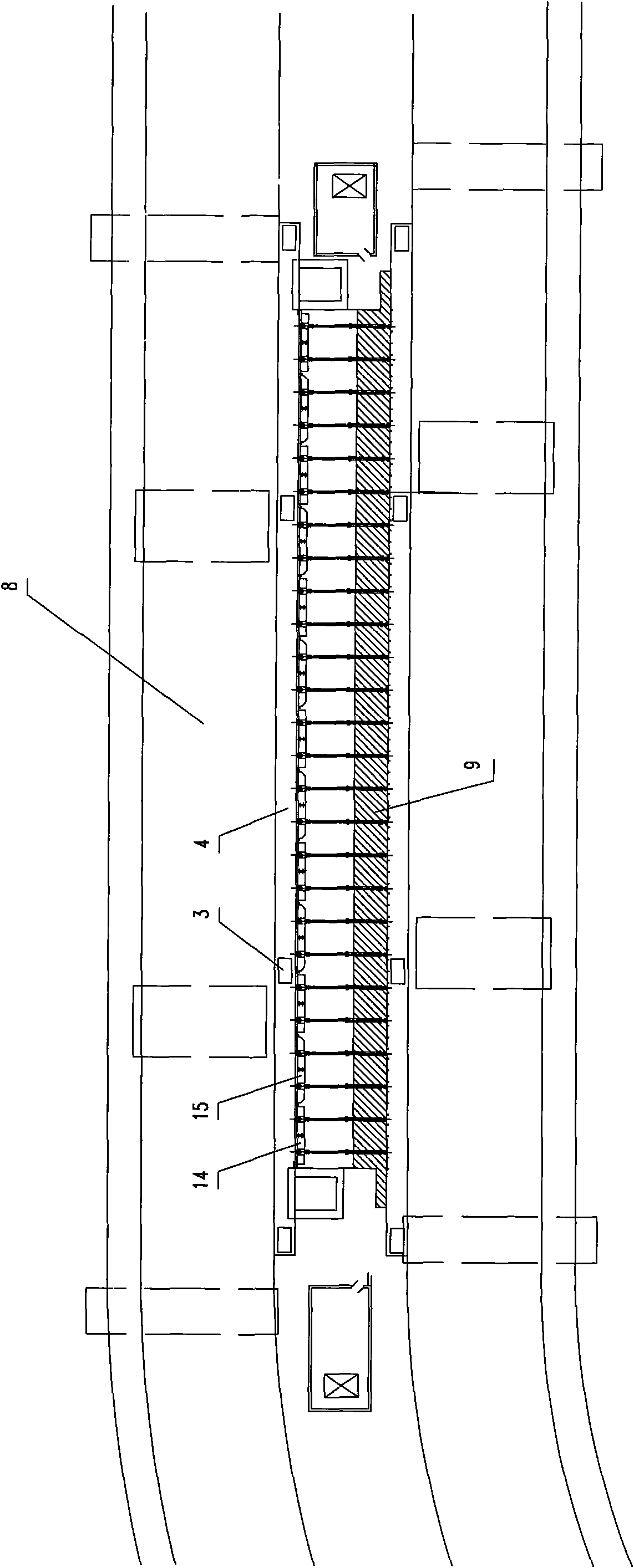

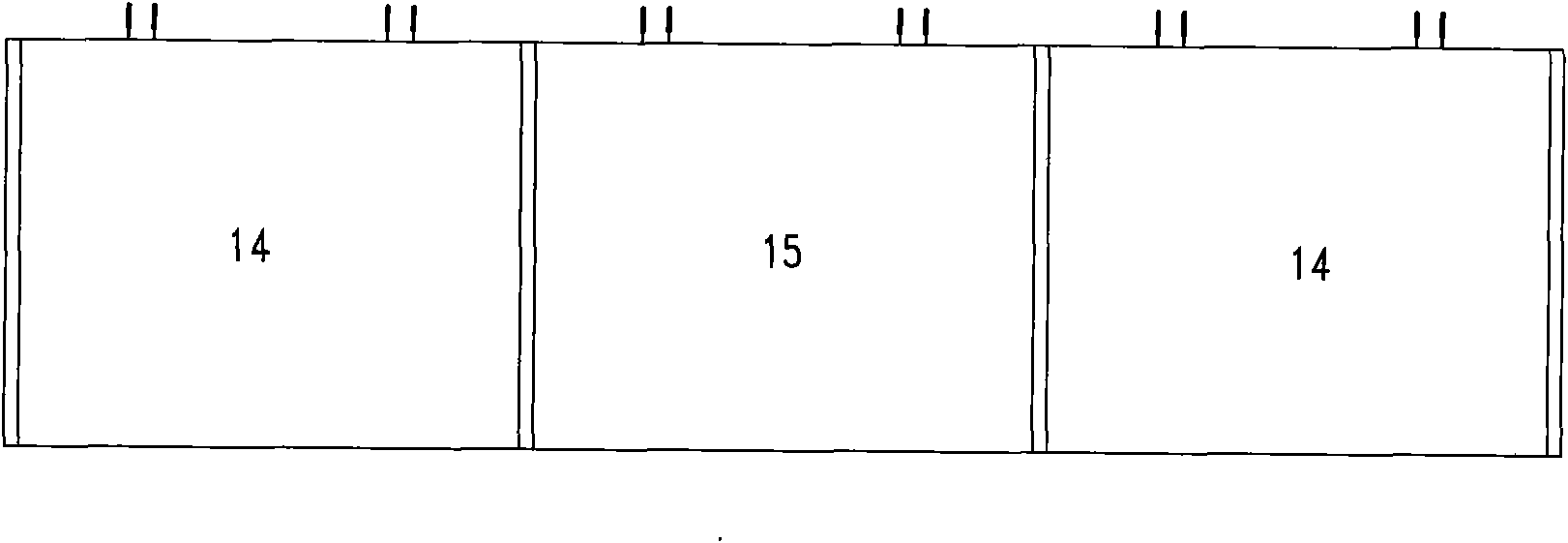

[0028] Figure 1 to Figure 5The preferred technical solution of the present invention is shown. As can be seen from the figure, the large-span hydraulic upturning gate is hidden in the isolation zone between the double-width bridges 8, and is mainly composed of a gate, a hydraulic hoist 6, a hydraulic pump station and a control room. The gate is composed of 3 One or more than three unit gates are arranged horizontally. The odd number of the unit gates is A-type gate 14, and the even number is B-type gate 15. Each of the A and B-type gates 14 and 15 is an integral plane steel gate. The side of the B-type door 15 and the bottom of the A and B-type doors 14 and 15 are provided with limit devices. The bottom limit position can limit the water-stop compression of the unit gate, and provide a limit when the bottom sill is locked. This lateral limiting device is arranged on the side beam of B-type door 15, and its main function is to limit the lateral mutual position between A-type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com