A plastic electrode tube for electroosmotic drainage

A technology of plastic pipe and drainage method, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of low drainage efficiency, affecting construction efficiency, weakening of electric field distribution, etc., to improve drainage efficiency, improve drainage efficiency, electric field Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

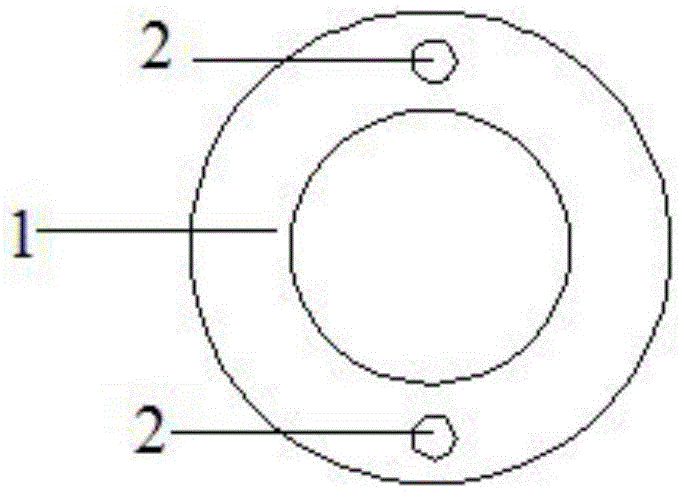

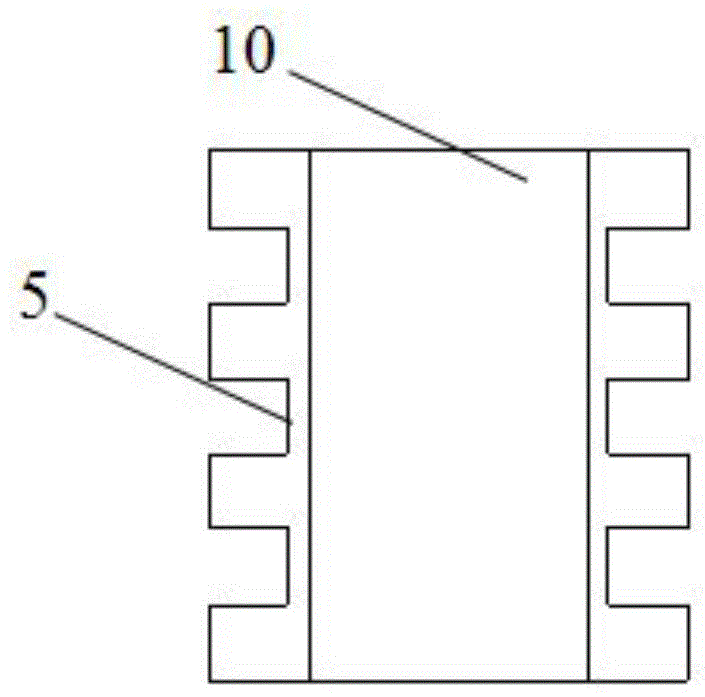

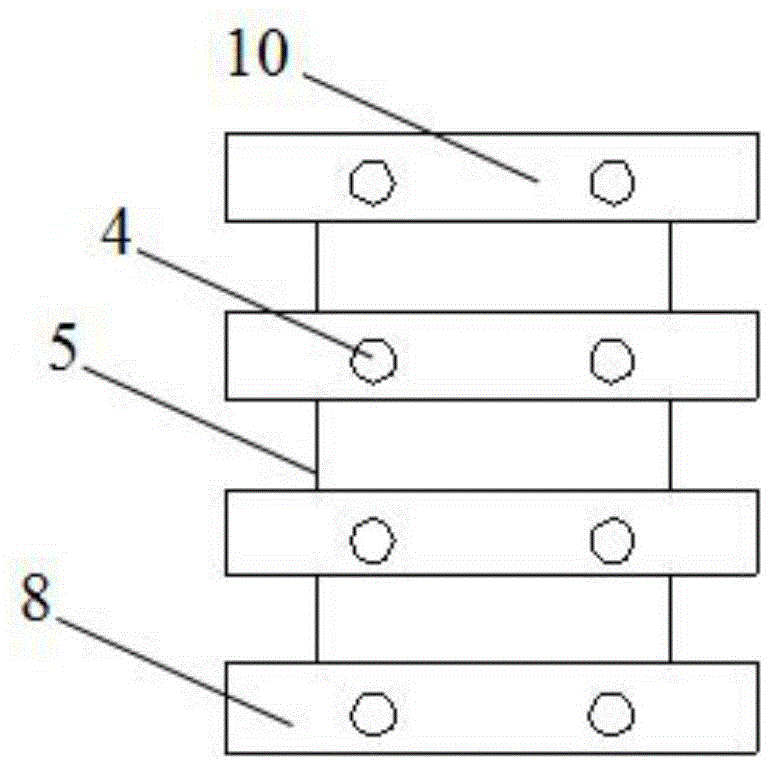

[0039] Such as Figure 1-3 As shown, in the present embodiment, the conductive plastic pipe 1 is made of materials including polyethylene, carbon black and graphite, and the resistivity is 10 -3 Ω·m. The conductive plastic pipe 1 is 6m long and is in the shape of a corrugated pipe 10. Annular grooves 5 and annular protrusions 8 extend from the bottom of the corrugated pipe 10 in a staggered arrangement to the top. The inner diameter of the conductive plastic pipe 1 is 20-50 cm. The thickness is 0.8-1mm, the 8 corrugated protrusions are 5mm apart, and the 5 annular grooves are 3mm deep.

[0040] The conductive plastic tube 1 includes two metal wires 2 located at symmetrical positions in the center of the tube. The metal wires 2 are wrapped in conductive plastic and run through the entire plastic electrode tube axially from top to bottom. The metal wire is copper wire with a diameter of 1mm.

[0041] Drainage holes 4 are evenly spaced on the annular protrusions 8 of the condu...

Embodiment 2

[0044] Such as Figure 4-5 As shown, in the present embodiment, the conductive plastic pipe 1 is made of materials including polyethylene, carbon black and graphite, and the resistivity is 10 -3 Ω·m. In this embodiment, the length of the conductive plastic pipe 1 is 8m, and the shape is a threaded pipe 11. The spiral grooves 6 and the spiral protrusions 9 are alternately arranged from the bottom of the outer wall of the conductive plastic pipe 1 to the top, and the inner diameter of the threaded pipe 11 is 25 ~ 55cm, the thickness of the pipe wall is 0.7-1mm, the distance between the spiral protrusions 9 is 4mm, and the spiral grooves 6 are about 2.5mm.

[0045] The conductive plastic pipe 1 includes four metal wires 2 arranged symmetrically about the axis inside the pipe. The metal wires are wrapped in the conductive plastic and run through the entire conductive plastic pipe 1 from top to bottom in the axial direction. Metal wire 2 is copper wire with a diameter of 1mm.

...

Embodiment 3

[0049] Such as Figure 6-7 As shown, in the present embodiment, the conductive plastic pipe 1 is made of materials including polyethylene, carbon black and graphite, and the resistivity is 10 -3 Ω·m. In this embodiment, the axial grooves 7 and axial protrusions 12 on the conductive plastic pipe 1 are evenly spaced along the circumference of the pipe and extend from the bottom to the top of the conductive plastic pipe 1. The length of the conductive plastic pipe 1 is 10 m, and the inner diameter is 25 ~ 50cm, the thickness of the pipe wall is 0.7-1.2mm, the distance between the grooves 7 is 3mm, and the depth of the groove is about 5mm.

[0050] The conductive plastic tube 1 includes two metal wires 2, which are arranged symmetrically about the axis inside the tube. The metal wires 2 are wrapped in the conductive plastic and run through the entire conductive plastic tube 1 from top to bottom in the axial direction. Metal wire 2 is copper wire with a diameter of 1.5mm.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com