Composite industrial filtration fabric structure with high resistance

A filter fabric, industrial technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of surface quality, bearing capacity, high temperature resistance and corrosion resistance, high production and use costs, insufficient use flexibility and other problems , to achieve the effect of reducing daily maintenance, long service life, good fiber fixation and recycling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

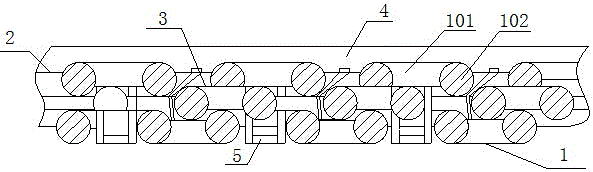

[0015] Such as figure 1 A composite industrial filter fabric structure with high resistance is shown, including forming layer 1 in contact with pulp, positioning layer 2 in contact with paper machine, adsorption transition layer 3 for connecting forming layer and positioning layer and guiding The guide weft 4, wherein the forming layer 1, the positioning layer 2 and the adsorption transition layer 3 are all distributed parallel to each other, wherein the adsorption transition layer 3 is located between the forming layer 1 and the positioning layer 2, and offsets the forming layer 1 and the positioning layer 2 respectively , the forming layer 1, the positioning layer 2 and the adsorption transition layer 3 are all woven by the weft 101 and the warp 102, and the weft 101 and the warp 102 are all perpendicular to each other, and the weft 101 and the warp 102 of the forming layer 1 are all connected with the positioning layer 2. The weft threads 101 and warp threads 102 are distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com