Method of producing ultrahigh-viscosity-index lubricant base oil

A technology for lubricating base oil and viscosity index, which is applied in lubricating compositions, base materials, petroleum industry, etc., can solve the problems of changes in product yield and product properties, complex reactions, and many Fischer-Tropsch synthetic wax conversion and processing steps. , to achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

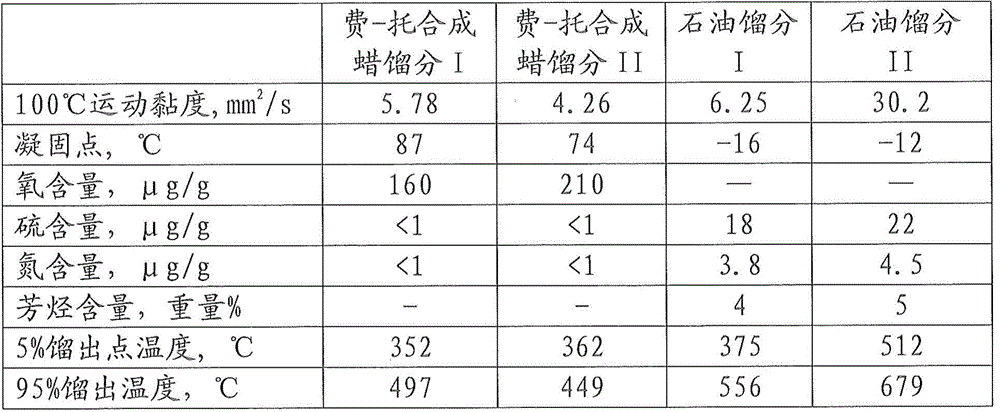

[0049] The reaction is filled with catalysts ISC-1 and RLF-10 L The Fischer-Tropsch synthetic wax fraction I and the petroleum fraction II are mixed in a mass ratio of 1:1 to obtain the Fischer-Tropsch synthetic wax fraction feed.

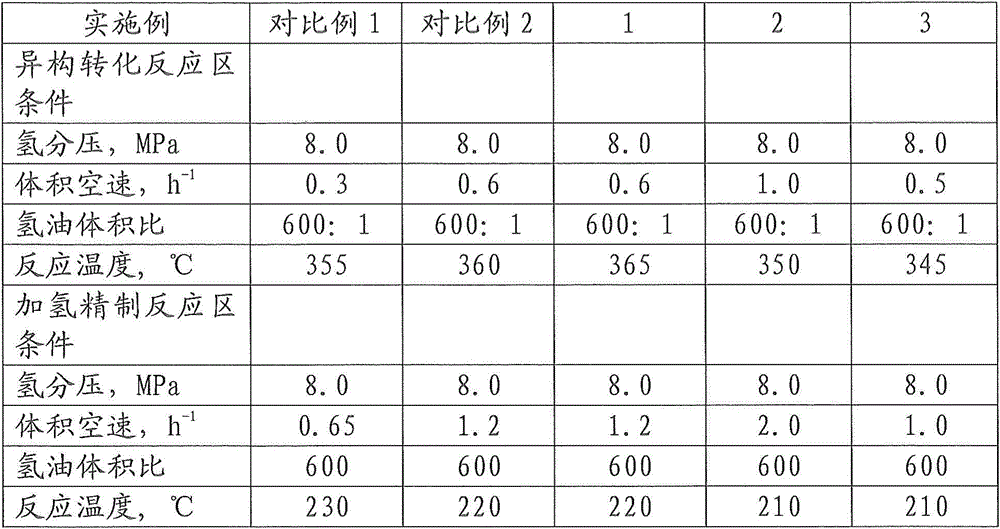

[0050] The feed was sequentially contacted with a wax hydroisomerization catalyst and a hydrofining catalyst for reaction. The reaction conditions are shown in Table 2.

[0051] The reaction products were separated to obtain lubricating oil base oil. The yield and properties of the lubricating base oil are shown in Table 3.

Embodiment 2

[0053] The reaction is filled with catalysts ISC-1 and RLF-10 L The Fischer-Tropsch synthetic wax fraction I and petroleum fraction II are mixed in a mass ratio of 0.3:1 to obtain the Fischer-Tropsch synthetic wax fraction feed.

[0054] The feed was sequentially contacted with a wax hydroisomerization catalyst and a hydrofining catalyst for reaction. The reaction conditions are shown in Table 2.

[0055] The reaction products were separated to obtain lubricating oil base oil. The yield and properties of the lubricating base oil are shown in Table 3.

Embodiment 3

[0057] The reaction is filled with catalysts ISC-1 and RLF-10 L The Fischer-Tropsch synthetic wax fraction II and the petroleum fraction II are mixed at a mass ratio of 0.6:1 to obtain the Fischer-Tropsch synthetic wax fraction feed.

[0058] The feed was sequentially contacted with a wax hydroisomerization catalyst and a hydrofining catalyst for reaction. The reaction conditions are shown in Table 2.

[0059] The reaction products were separated to obtain lubricating oil base oil. The yield and properties of the lubricating base oil are shown in Table 3.

[0060] The properties of the high boiling point petroleum fraction I and petroleum fraction II products after isomerization conversion and hydrorefining are shown in Table 4. The sulfur content, nitrogen content, pour point and other indicators of the product are greatly improved. It can be recovered as a lubricating oil base oil product and can also be recycled as a high boiling point petroleum fraction in the present invention....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com