Multi-stage M-shaped air way liquid desiccant dehumidification air-conditioning system utilizing ultrasonic atomization technology

A technology of solution dehumidification air conditioning and ultrasonic atomization, which is applied in the field of solution dehumidification air conditioning system and multi-stage M-shaped air channel solution dehumidification air conditioning system, which can solve the problems of limited dehumidification efficiency, large system resistance, and large space occupation, and achieve gas-liquid Increased contact area, small system resistance, and reduced air-conditioning energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The concrete implementation of the present invention is described further below in conjunction with accompanying drawing:

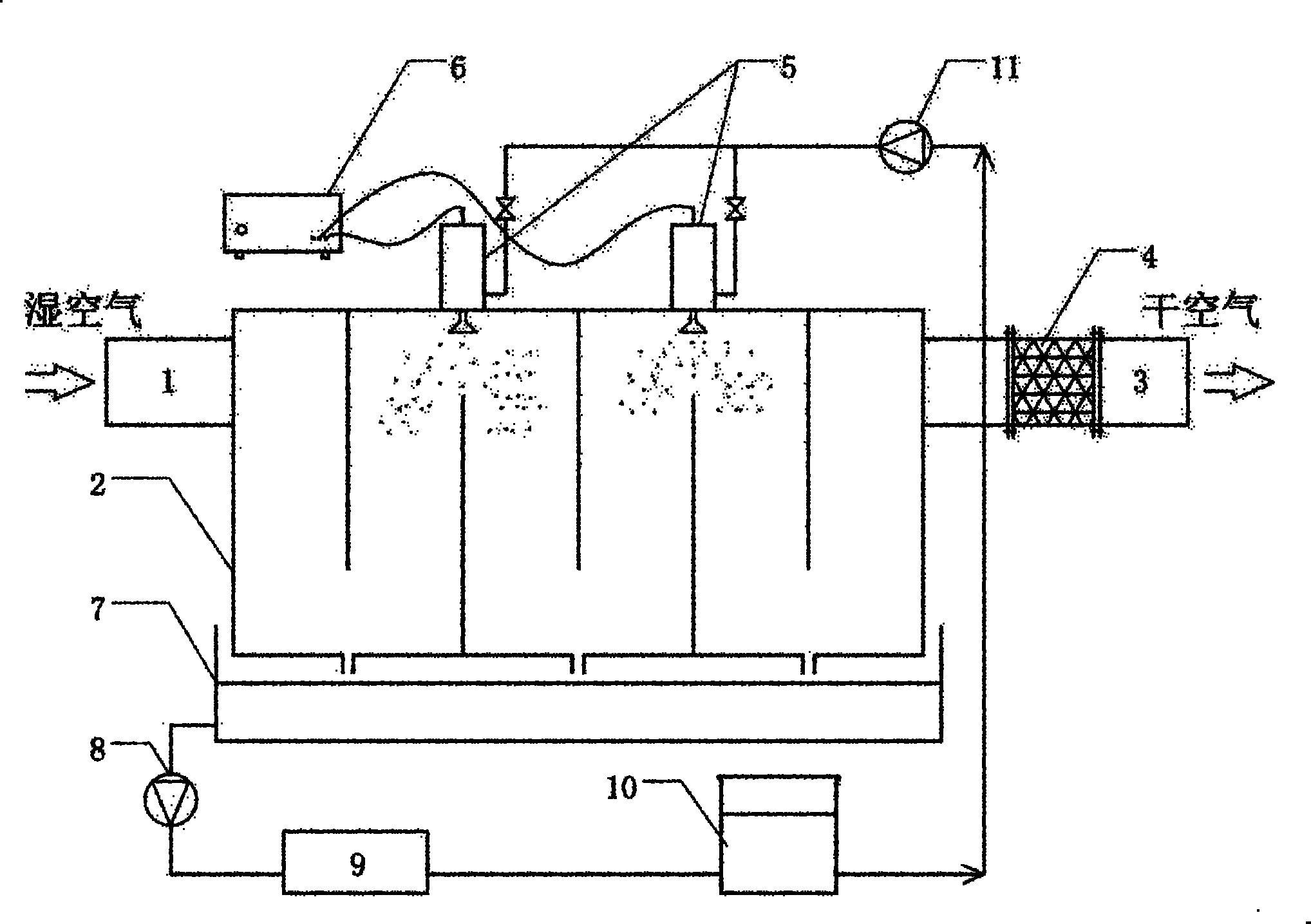

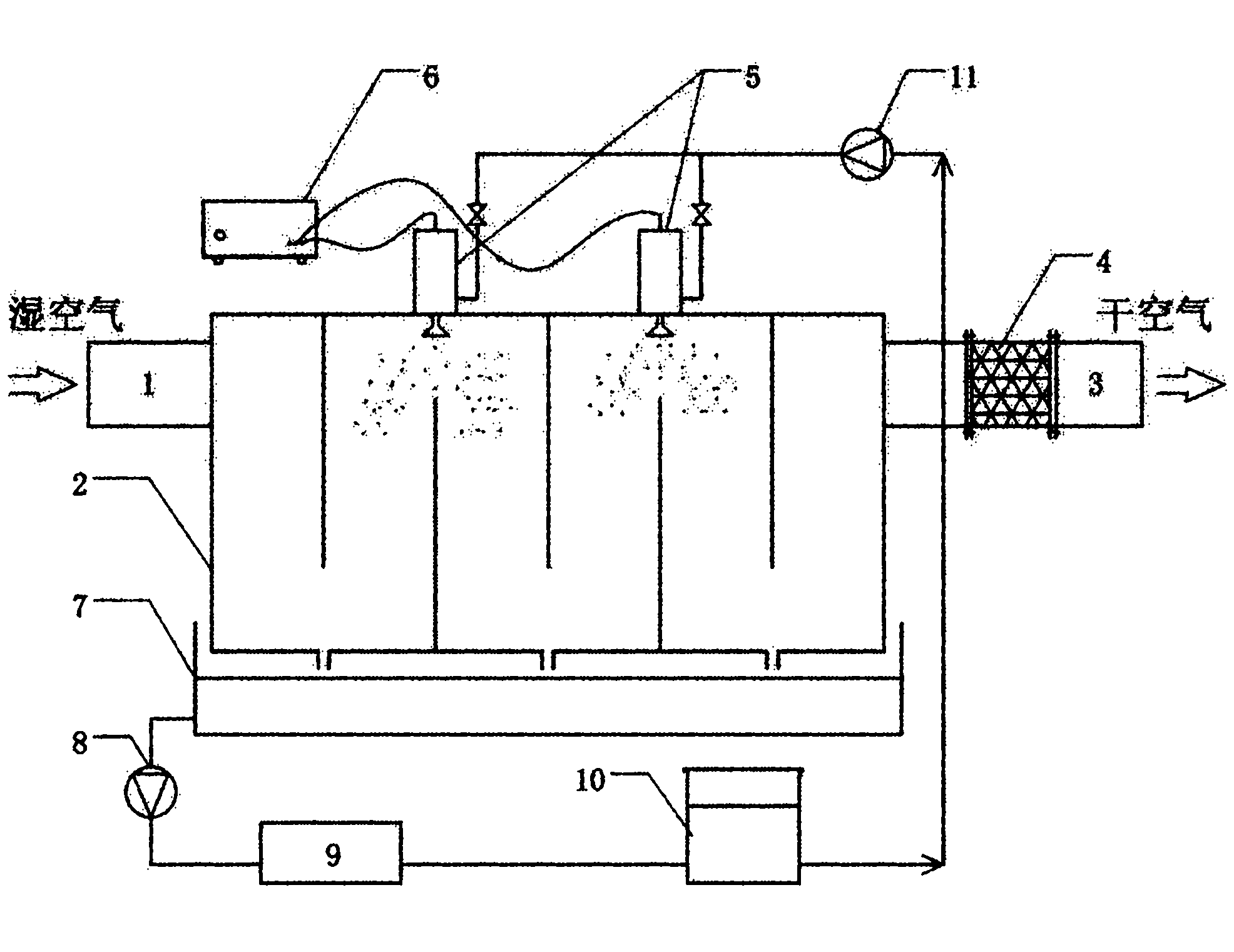

[0012] Such as figure 1 As shown, the present invention includes an air inlet pipe 1, a dehumidification air-conditioning box 2, an exhaust pipe 3, a defogging device 4, two salt solution atomization devices 5, an ultrasonic generator 6, a dilute solution tank 7, and a first solution pump 8 , regeneration device 9, concentrated solution cylinder 10 and second solution pump 11, wherein the dehumidification and air conditioning box 2 adopts a cubic structure box made of corrosion-resistant PVC material, and the inside is divided into 2-3 levels M by a baffle plate of corrosion-resistant PVC material shaped air channel. Two ultrasonic salt solution atomization devices 5 are made of corrosion-resistant alloy materials, and are respectively installed on the top of the dehumidification air-conditioning box 2 . The signal output ends of the ultrasonic g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com