Composite dehumidifying method based on film and its apparatus and application

A technology of equipment and composite support, which is applied in the field of composite dehumidification, can solve the problems that exhaust heat and humidity cannot be utilized, low dew point dehumidification cannot be realized, and waste heat and humidity cannot be recovered, so as to achieve good economic benefits, adapt measures to local conditions, and realize various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

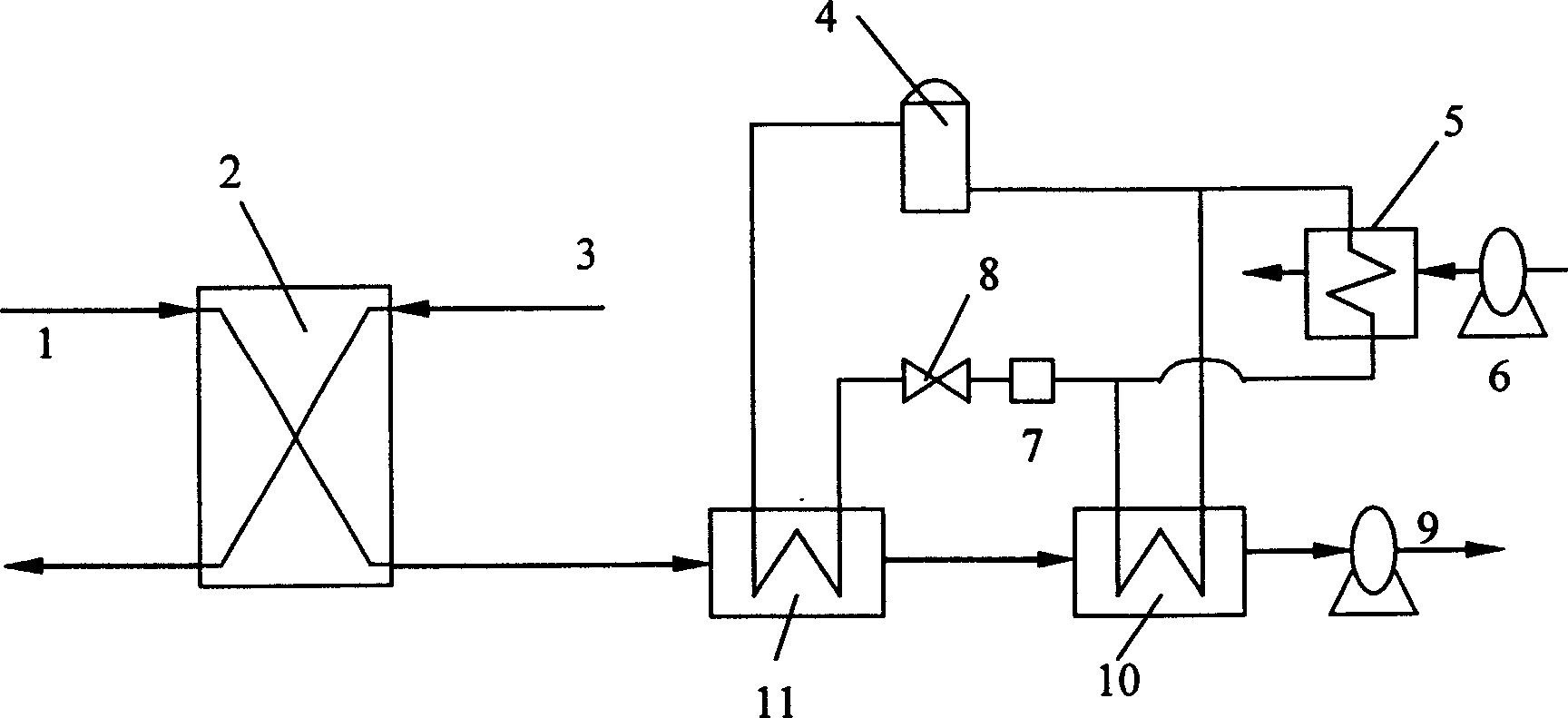

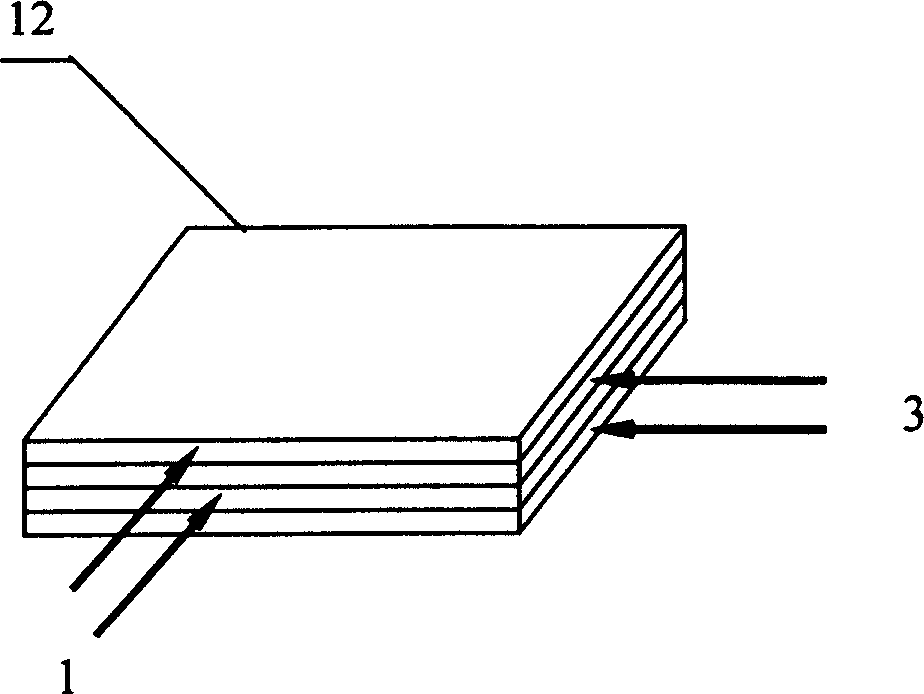

[0024] The specific structure of the present invention is as figure 1 shown by figure 1 It can be seen that this membrane-based composite dehumidification equipment is composed of a membrane exchanger 2 connected with a compression refrigeration dehumidification device, and the structure of the membrane exchanger is as follows: figure 2 As shown, it includes a selective permeable membrane or a composite supporting liquid membrane 12, a fresh air duct 1, and an exhaust duct 3, and a selective permeable membrane or a composite supporting liquid membrane 12 is set between the fresh air duct 1 and the exhaust duct 3; The compression refrigeration dehumidification device includes a compressor 4, condensers 5, 10, fans 6, 9, a liquid receiver 7, an expansion valve 8, and an evaporator 11, and the compressor 4 is connected to two parallel condensers 5, 10 through pipelines. One of the condensers 5 is set opposite to the fan 6, cooled by the outside air driven by the fan 6, and the ...

Embodiment 2

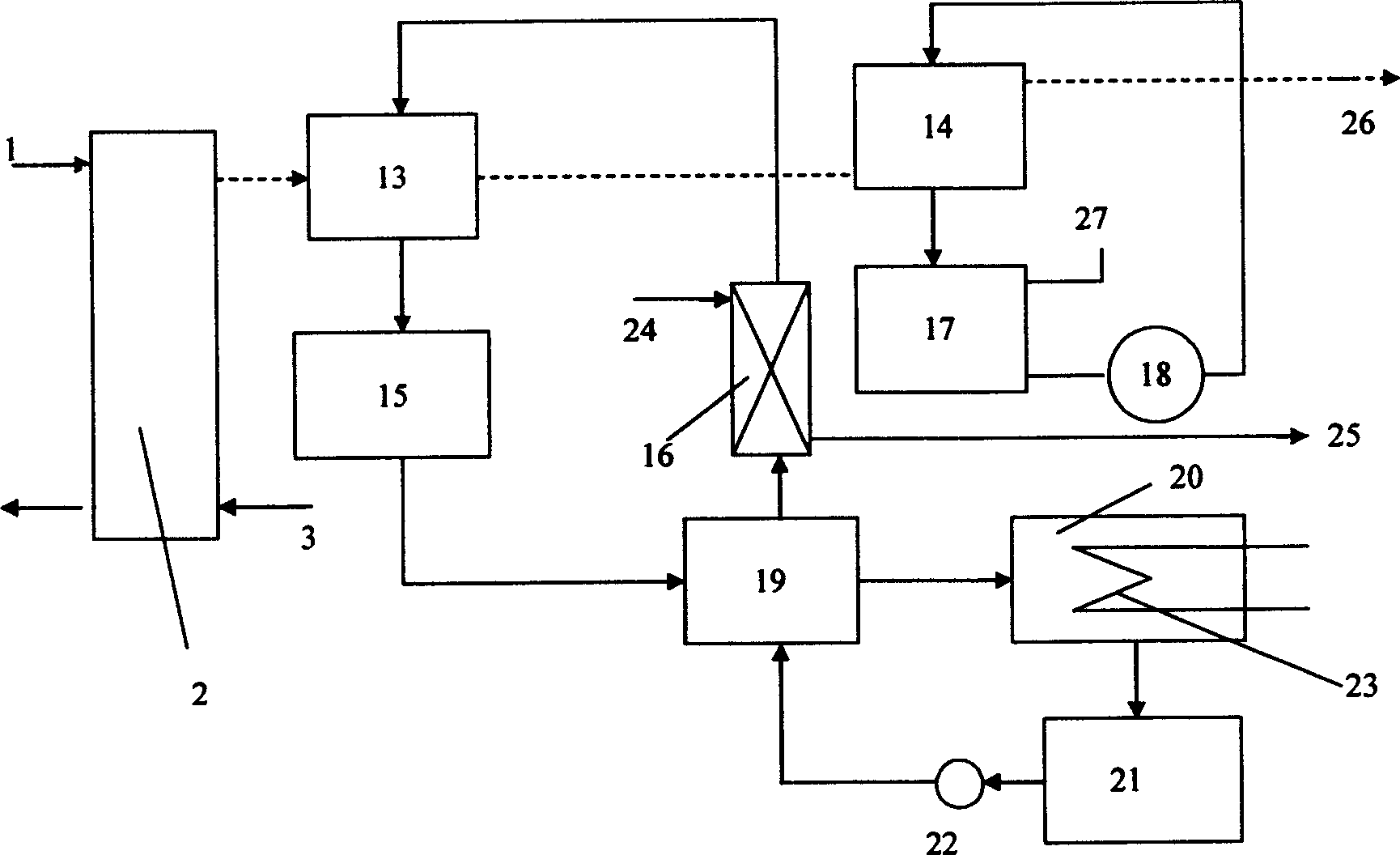

[0028] Another structural form of the present invention is as image 3 shown by image 3 It can be seen that this membrane-based composite dehumidification equipment is composed of a membrane exchanger 2 connected with a liquid absorption dehumidification device, and the structure of the membrane exchanger 2 is the same as in Example 1 (see figure 2 ); the liquid absorption and dehumidification device comprises an absorber 13, an evaporative cooler 14, a cold liquid storage device 15, a water cooler 16, a water storage tank 17, a water pump 18, a solution heat exchanger 19, a regenerator 20, and a thermal liquid storage device 21. Solution pump 22, the absorber 13 is connected to the cold liquid reservoir 15 through a pipeline, the cold liquid reservoir 15 is connected to the solution heat exchanger 19, and the solution heat exchanger 19 is connected to the regenerator 20 at the same time, and the regeneration Heating coil 23 is arranged in device 20; Another group of inlet ...

Embodiment 3

[0032] Another structural form of the present invention is as Figure 4 shown by Figure 4 It can be seen that this membrane-based composite dehumidification equipment is composed of a membrane exchanger 2 connected with a runner dehumidification device, and the structure of the membrane exchanger 2 is the same as in Example 1 (see figure 2 ); said runner dehumidification device comprises dehumidification runner 35 (formed of hygroscopic solids such as lithium chloride, silica gel, calcium chloride), heater 29, heat exchanger 30, regeneration fan 31, motor 33, belt 34, fresh air Fan 36, regeneration air inlet pipe 32, regeneration air outlet pipe 28, drying air outlet pipe 26. Motor 33 is connected with dehumidification runner 35 through belt 34 (also can be provided with gear outside dehumidification runner, motor 33 is connected with dehumidification runner 35 through gear set and carries out transmission), and the regeneration area of described dehumidification runner 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com