One-dimensional MnO2@NiMoO4 core shell heterojunction composite material and preparation method and application thereof

A composite material and heterojunction technology, which is applied in the field of one-dimensional MnO2@NiMoO4 core-shell heterojunction composite material and its preparation, can solve the problems of poor electrochemical properties, unstable cycling, and poor rate performance of electrode materials. To achieve the effect of easy regulation, low cost and convenient post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

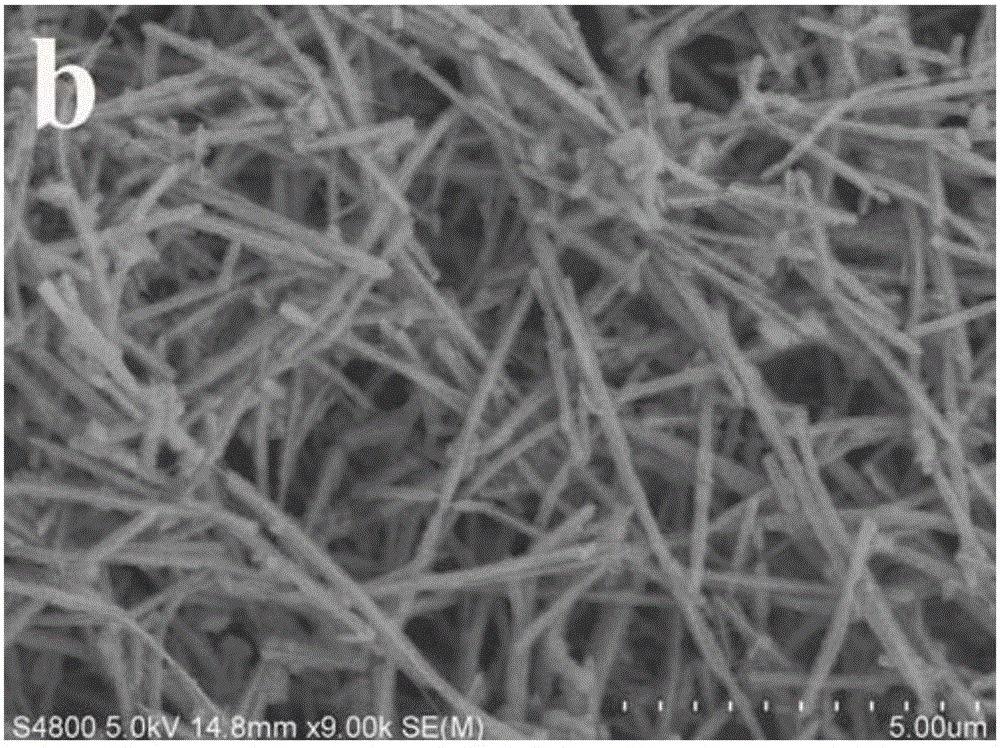

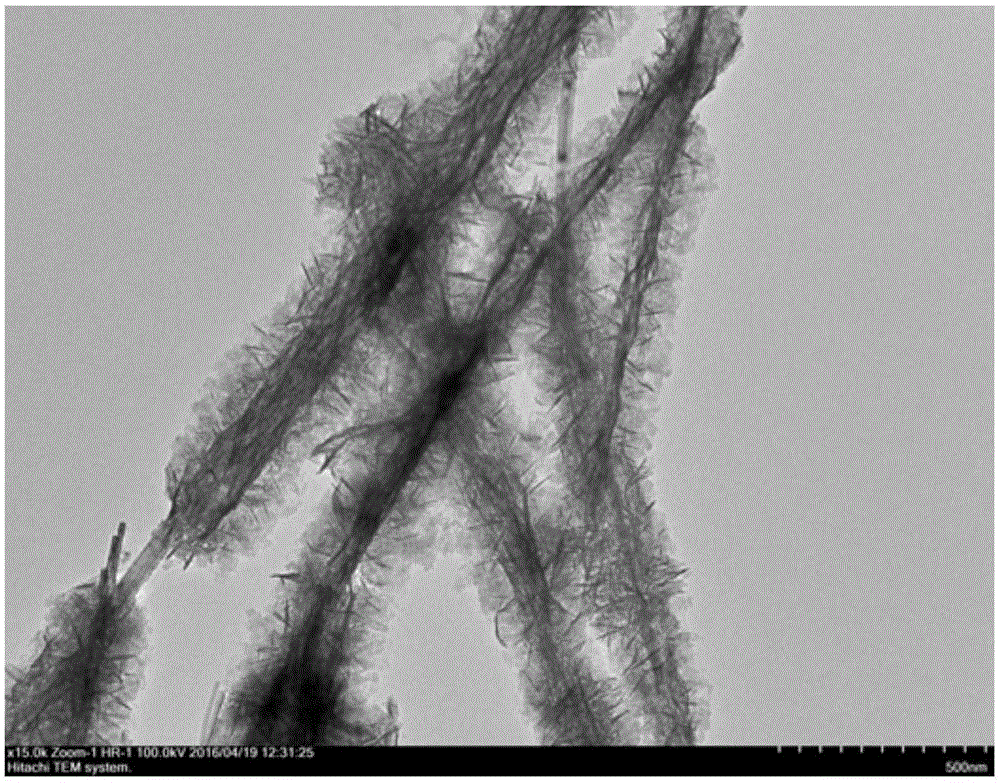

[0027] The invention provides a one-dimensional MnO 2 @NiMoO 4 A method for preparing a core-shell heterojunction composite material, the preparation method comprising:

[0028] 1) MnO 2 Preparation of nanowire monomers;

[0029] 2) Combine urea, soluble nickel salt, soluble molybdate and MnO 2 Contact reaction of nanowire monomers in water to produce one-dimensional MnO 2 @NiMoO 4 Core-shell heterojunction composites.

[0030] In step 2) of the above-mentioned preparation method, the consumption of each material can be selected in a wide range, but in order to make the composite material obtained have more excellent specific capacitance and cycle stability, preferably, relative to 0.2-0.6mmol MnO 2 Nanowire monomer, the amount of urea is 2-6mmol, the amount of soluble nickel salt is 1-3mmol, and the amount of soluble molybdate is 1-3mmol;

[0031] In step 2) of the above-mentioned preparation method, the amount of water can be selected in a wide range, but in order to...

preparation example

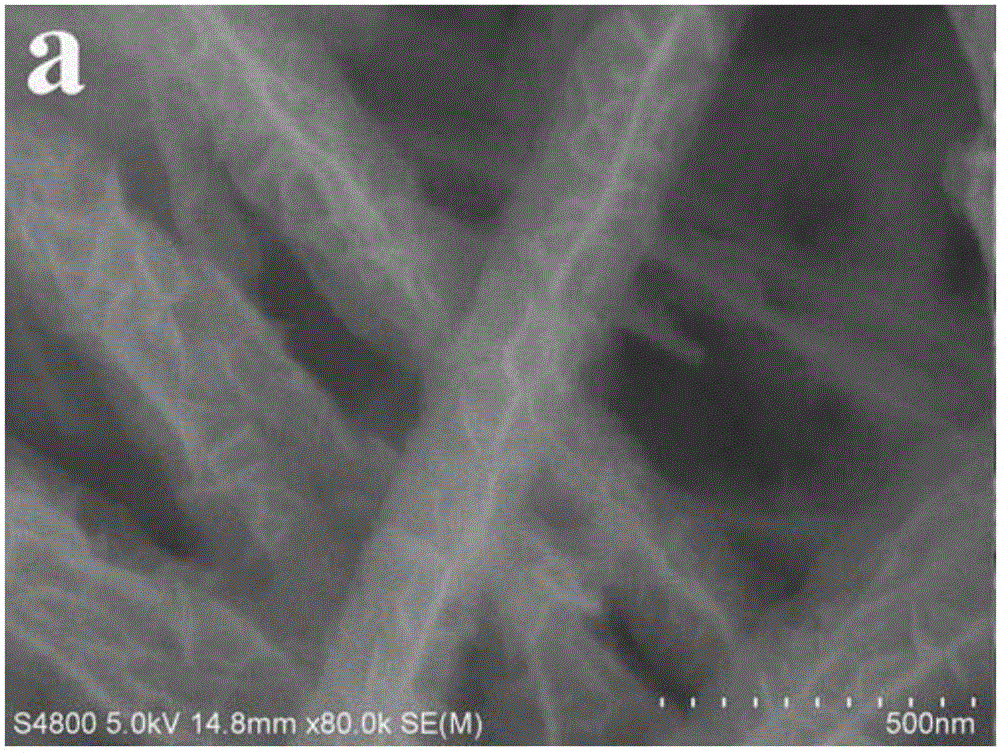

[0043] MnO 2 Preparation of nanowire monomers:

[0044] 10ml of KMnO 4 Aqueous solution (0.04mol / L) and 10ml of NH 4 Cl aqueous solution (0.04mol / L) was reacted at 180°C for 20h to prepare MnO 2 nanowire monomer.

Embodiment 1

[0046] 1) MnO 2 Nanowire monomer (0.4mmol) was ultrasonically dispersed in 20mL water for 3min to prepare MnO 2 Nanowire monomer aqueous solution;

[0047] 2) Add 4mmol urea and 1mmol nickel chloride to the above MnO 2 Nanowire monomer aqueous solution and stirred at 25°C for 30min; then added 1mmol sodium molybdate and ultrasonically oscillated at 25°C for 5min; then placed at 110°C for 12h; finally cooled, deionized water and absolute ethanol Each was washed 3 times and dried at 60°C to obtain one-dimensional MnO 2 @NiMoO 4 Core-shell heterojunction composite A1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com