Method for double bond isomerization of butene

A technology of isomerization and butene, applied in the field of isomerization of butene double bonds, can solve the problems of low selectivity of reaction products, short catalyst activity period, etc., and achieve the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

[0017] The preparation method of catalyst I:

[0018] Weigh 100 grams of light magnesia powder, add 20 grams of astragalus powder, and then add 30 grams of water, stir thoroughly, extrude, dry and roast to obtain the magnesia catalyst.

[0019] The preparation method of catalyst II:

[0020] With reference to document CN200310108177.5, according to the molar ratio of silicon to aluminum (SiO 2 / Al 2 o 3 ) is the slurry containing silicon, aluminum, templating agent and water of the ratio preparation of 200 respectively, at 130 ℃, under the condition of 70 hours, synthesizes 150 grams of ZSM-5 molecular sieves, then adds 18 grams of 40% (weight) colloidal silica and mixes Afterwards, extruded, dried at 120°C, and calcined at 550°C for 4 hours to obtain the required catalyst II.

[0021] According to the weight loading ratio of the catalyst I and the catalyst II being 1:1, the required amounts of the catalyst I and the catalyst II were weighed respectively, and the catalyst ...

Embodiment 10~19

[0025] According to each step of embodiment 1, just catalyst II is silicon aluminum molar ratio (SiO 2 / Al 2 o 3 ) 300 ZSM-5 molecular sieve, using refinery raffinate II as raw material (by weight percentage, n-butane 17.8%, cis-2-butene 22.2%, trans-2-butene 60%), at a temperature of 320 hours -1 , under the condition of 0.1MPa pressure, the reaction results of isomerization of butene-2 to butene-1 under different reaction weight space velocity conditions are shown in Table 2:

[0026] Table 2

[0027] serial number

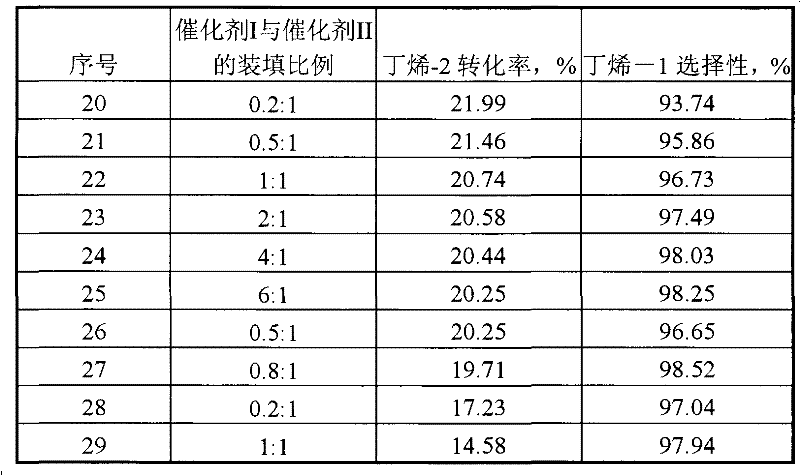

Embodiment 20~29

[0029] According to each step of embodiment 1, just catalyst II is silicon aluminum molar ratio (SiO 2 / Al 2 o 3 ) 800 ZSM-5 molecular sieve, using refinery raffinate II as raw material (by weight percentage, n-butane 17.8%, cis-2-butene 22.2%, trans-2-butene 60%), at a temperature of 320 hours -1 , the pressure is 0.5MPa, the weight space velocity is 5h -1 Under the conditions, the reaction results of isomerization of butene-2 to butene-1 under different weight loading ratios of catalyst I and catalyst II are shown in Table 3 below:

[0030] table 3

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com