Regeneration method for nickel-base hydrogenation catalyst

A hydrogenation catalyst, catalyst technology, applied in catalyst regeneration/reactivation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of increasing energy consumption, increasing equipment investment, increasing crystal grain size It can reduce the cost of hydrogenation, prolong the operation period, and reduce the regeneration temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~18

[0025] The hydrogenation reactor is a stainless steel tubular reactor of φ 25mm × 1000mm, and the reaction tube filling diameter is 25ml of a nickel-containing catalyst of 1 / 8 ", and the bottom of the reactor is filled with inert ceramic balls. The Ni content in the catalyst is 22%, and the NiO content is 46%, with the remainder being the carrier.

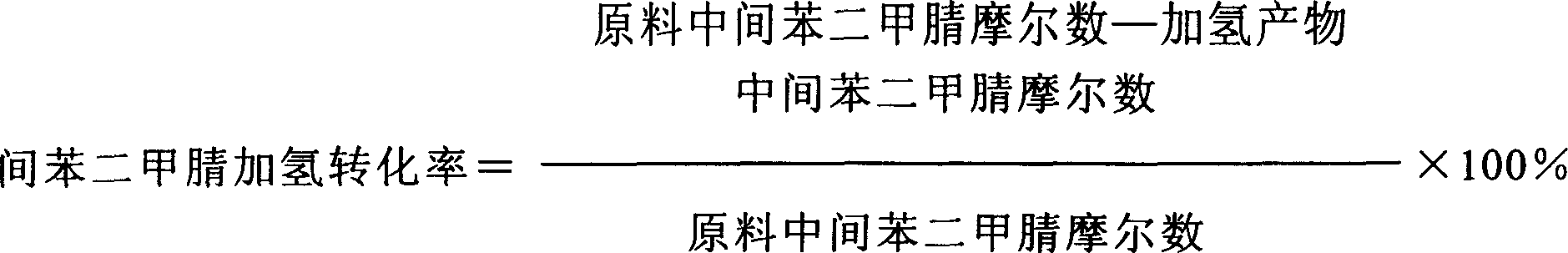

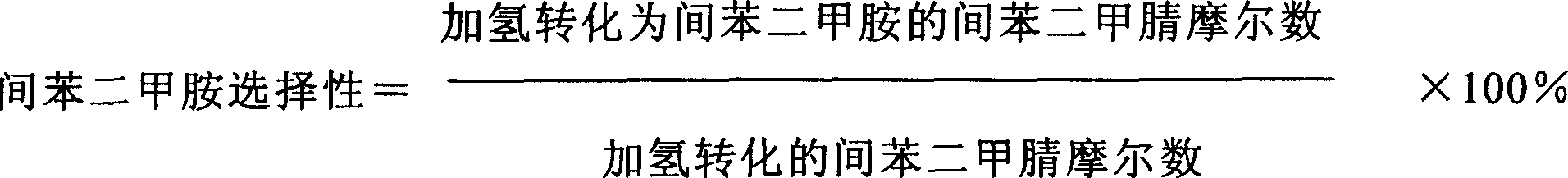

[0026] The m-xylene-isophthalonitrile-liquid ammonia (mass ratio is 50:8:42) solution is preheated and then pumped into the hydrogenation reactor from the top at a set rate, and hydrogen enters through the gas distributor. In the reactor, the raw material is mixed with hydrogen and enters the catalyst bed for hydrogenation reaction. The hydrogenation inlet temperature is 70°C, the hydrogen pressure is 11.5MPa, the molar ratio of hydrogen to raw material isophthalonitrile is 10, and the liquid of the reaction material is The hourly space velocity is 3.0h -1 . When the catalyst is in long-term operation, in order to make the conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com