Method for preparing acetic acid through carbonylation of methanol

一种甲醇羰基化、甲醇的技术,应用在一氧化碳反应制备羧酸、化学仪器和方法、催化剂活化/制备等方向,能够解决乙酸选择性不高、催化剂稳定性不够理想等问题,达到节约分离能耗、节约产品深度纯化成本、稳定性增强的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

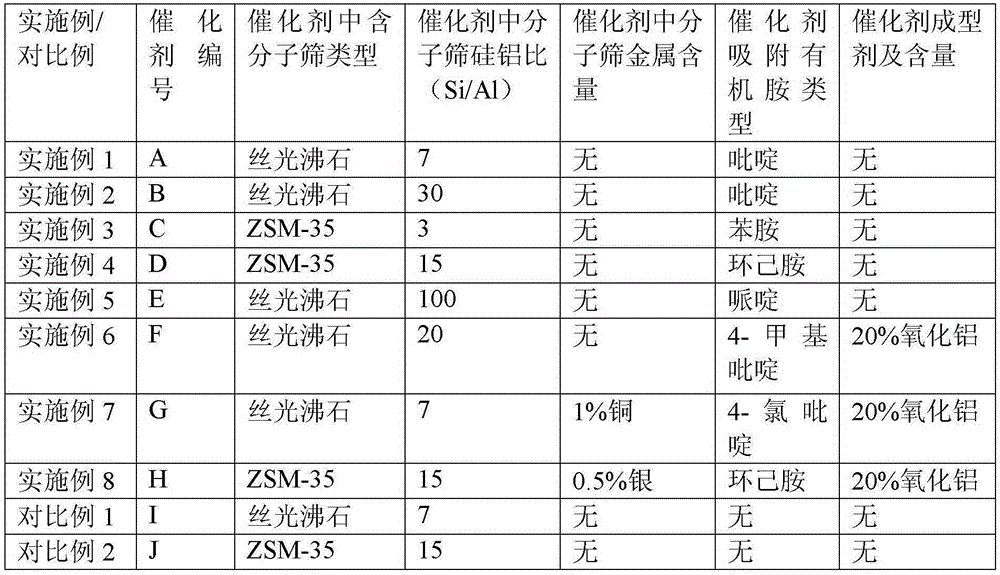

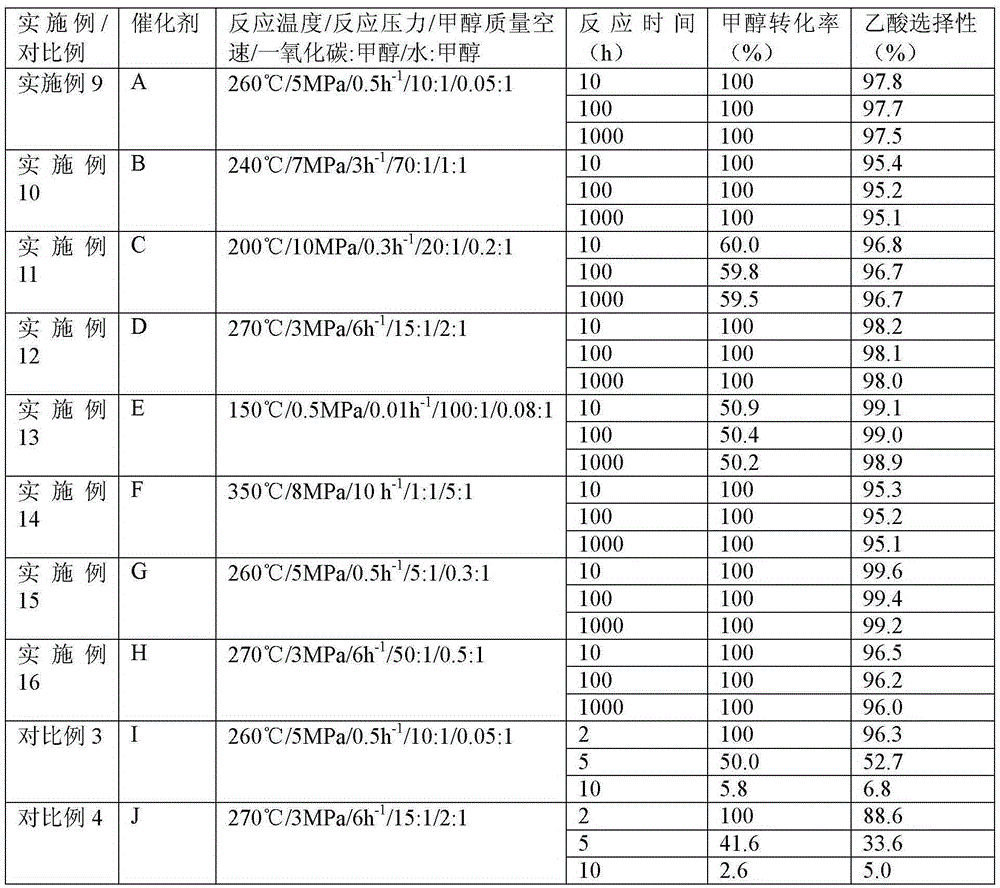

Embodiment 1

[0065] One kilogram of sodium mordenite with Si / Al=7 was exchanged three times with 0.8 mol / L ammonium nitrate aqueous solution at 80°C to obtain ammonium mordenite. Calcining at 500° C. for 4 hours in an air atmosphere to obtain hydrogen-type mordenite, and then tableting, crushing, and sieving to prepare 5-10 mesh particles. Then it is loaded into a stainless steel fixed-bed reactor with a diameter of 32mm, and at 280°C, under normal pressure, it is treated with 500ml / min of 0.3% molar concentration of pyridine and nitrogen gas mixture for 6 hours to adsorption saturation, and then at 280 ℃, purged with 500ml / min nitrogen for 3 hours under normal pressure, and then lowered to room temperature to prepare the acidic mordenite molecular sieve adsorbed by pyridine. As catalyst A, its composition is shown in Table 1.

Embodiment 2

[0067] One kilogram of sodium mordenite with Si / Al=30 was exchanged three times with 0.8 mol / L ammonium nitrate aqueous solution at 80°C to obtain ammonium mordenite. Calcining at 500° C. for 4 hours in an air atmosphere to obtain hydrogen-type mordenite, and then tableting, crushing, and sieving to prepare 5-10 mesh particles. Then it is loaded into a stainless steel fixed-bed reactor with a diameter of 32mm, and at 280°C, under normal pressure, it is treated with 500ml / min of 0.3% molar concentration of pyridine and nitrogen gas mixture for 6 hours to adsorption saturation, and then at 280 ℃, purged with 500ml / min nitrogen for 3 hours under normal pressure, and then lowered to room temperature to prepare the acidic mordenite molecular sieve adsorbed by pyridine, as catalyst B, whose composition is shown in Table 1.

Embodiment 3

[0069] One kilogram of sodium ZSM-35 with Si / Al=3 was exchanged three times with 0.8 mol / L ammonium nitrate aqueous solution at 80° C. to obtain ammonium ZSM-35. Calcined at 500°C for 4 hours in an air atmosphere to obtain hydrogen ZSM-35, and then pressed into tablets, crushed and sieved to prepare 5-10 mesh particles. Then it is loaded into a stainless steel fixed-bed reactor with a diameter of 32mm, and at 280°C, under normal pressure, it is treated with 500ml / min of aniline and nitrogen gas mixture containing 0.3% molar concentration for 6 hours until adsorption saturation, and then at 280 °C, purged with 500ml / min nitrogen for 3 hours under normal pressure, and then lowered to room temperature to prepare the acidic ZSM-35 molecular sieve adsorbed by aniline, as catalyst C, whose composition is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com