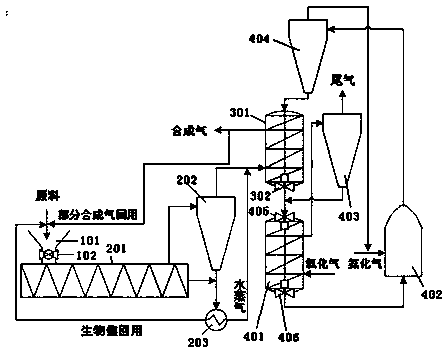

Method and system for preparing syngas from biomass through microwave pyrolysis

A biomass and synthesis gas technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, direct heating and dry distillation, etc., can solve the problem of low microwave absorption efficiency, increased energy consumption and gas consumption, process The problem of low economy is to achieve the effect of effective coupling and integration, recycling, and continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

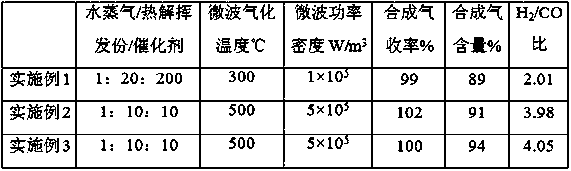

Embodiment 1

[0058] Mix 1 part of biomass semi-coke (carbon content 85%, hydrogen content 2%, oxygen content 11.9%, nitrogen content 1.1%, degree of graphitization 78%) and 5 parts 2.1% ammonia solution, then modify at 25 ℃ 6h, then according to the molar ratio of nickel oxide and ammonia in water as 1:9, add nickel oxide into the above reaction system and continue to stir until no solid dissolves. / min, 1℃ / min at 60~70℃, 0.5℃ / min at 70~80℃, 0.25℃ / min at 80~90℃) to 90℃ and keep for 6h. During this heating process, a precipitate gradually formed, and then the precipitate was separated and washed until the solution was neutral, dried at 80°C for 4 hours, and roasted at 300°C for 6 hours under a nitrogen atmosphere to obtain a biomass oil reforming catalyst BOWR-1, wherein The mass percentage of ammoniated biological semi-coke is 94.87% (carbon content 84.1%, hydrogen content 2.2%, oxygen content 10.5%, nitrogen content 3.2%, of which pyridine nitrogen accounts for 1.05%, pyrrole nitrogen acc...

Embodiment 2

[0060] Mix 1 part of bio-semi-coke (carbon content 74.2%, hydrogen content 3.9%, oxygen content 19.9%, nitrogen content 2%, degree of graphitization 45%) and 2 parts 10% ammonia solution, then modify and react at 30°C for 2 hours , and then according to the molar ratio of nickel oxide to ammonia water 1:7, nickel oxide was added to the above reaction system and continued to stir until no solid was dissolved. 70°C at 1°C / min, 70~80°C at 0.5°C / min, 80~90°C at 0.25°C / min) to 90°C and keep for 6 hours. During this heating process, a precipitate is gradually formed, and then the precipitate is separated and washed until the solution is neutral, dried at 150°C for 1 hour, and roasted at 500°C for 2 hours under a nitrogen atmosphere to obtain a biomass oil reforming catalyst BOWR-2, wherein The mass percentage of ammoniated biological semi-coke is 87.45% (carbon content 72%, hydrogen content 2.4%, oxygen content 19.5%, nitrogen content 6.1%, of which pyridine nitrogen accounts for 1....

Embodiment 3

[0062] Mix 1 part of bio-semi-coke (carbon content 74.2%, hydrogen content 3.9%, oxygen content 19.9%, nitrogen content 2%, degree of graphitization 45%) and 2 parts 20% ammonia solution, then modify and react at 50°C for 4 hours , and then according to the molar ratio of nickel oxide to ammonia water as 1:9, nickel oxide was added to the above reaction system and continued to stir until no solid was dissolved. min, 60~70°C at 1°C / min, 70~80°C at 0.5°C / min, 80~90°C at 0.25°C / min) to 90°C and keep for 6h. During this heating process, a precipitate is gradually formed, and then the precipitate is separated and washed until the solution is neutral, dried at 150°C for 1 hour, and roasted at 500°C for 2 hours under a nitrogen atmosphere to obtain a biomass oil reforming catalyst BOWR-3, wherein The mass percentage of ammoniated biological semi-coke is 80.47% (carbon content 72.5%, hydrogen content 4.4%, oxygen content 15.2%, nitrogen content 7.9%, of which pyridine nitrogen account...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of graphitization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com