A supercritical multi-component thermal fluid generator that can be directly used for thermal recovery of heavy oil

A multi-component thermal fluid and heavy oil thermal recovery technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of coking and carbon deposition, achieve the solution of coking and carbon deposition, good safety and easy maintenance and maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

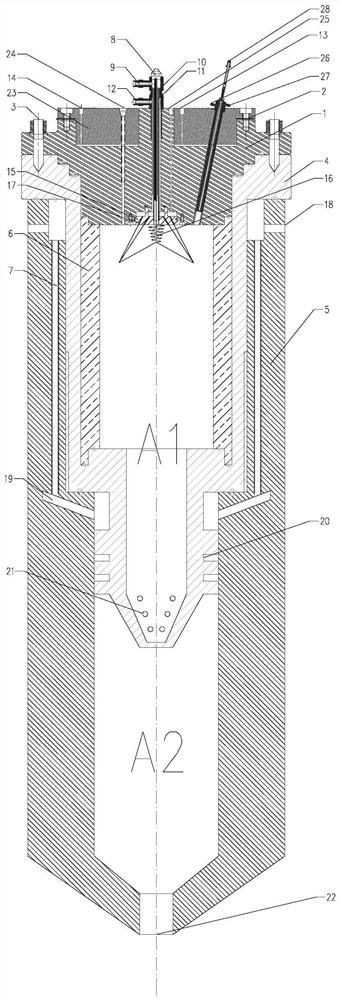

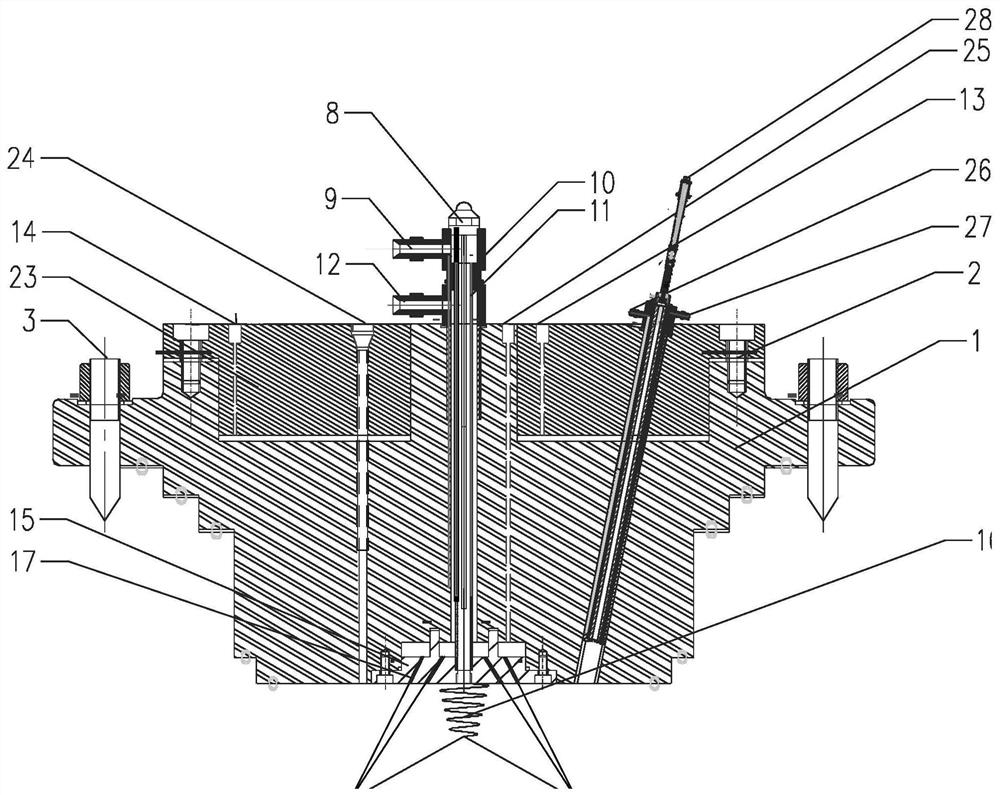

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings and examples.

[0035] The invention is a supercritical multi-component thermal fluid generating device which can be directly used for thermal recovery of heavy oil. The supercritical multi-component thermal fluid is obtained by burning fuel and oxidant under supercritical pressure and mixing the product with water. Especially suitable for heavy oil thermal recovery process, its fuel is not limited to crude oil, diesel oil, gasoline, coal slurry, ethanol, etc., and its oxidant is not limited to oxygen, air, hydrogen peroxide, etc.

[0036] like figure 1 and figure 2 As shown, the present invention mainly includes three parts: the reactor end cover 1 , the mixing cylinder 4 and the reactor wall 5 .

[0037] Among them, the mixing cylinder 4 is assembled in the upper part of the reactor wall 5, and is connected with the reactor end cover 1, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com