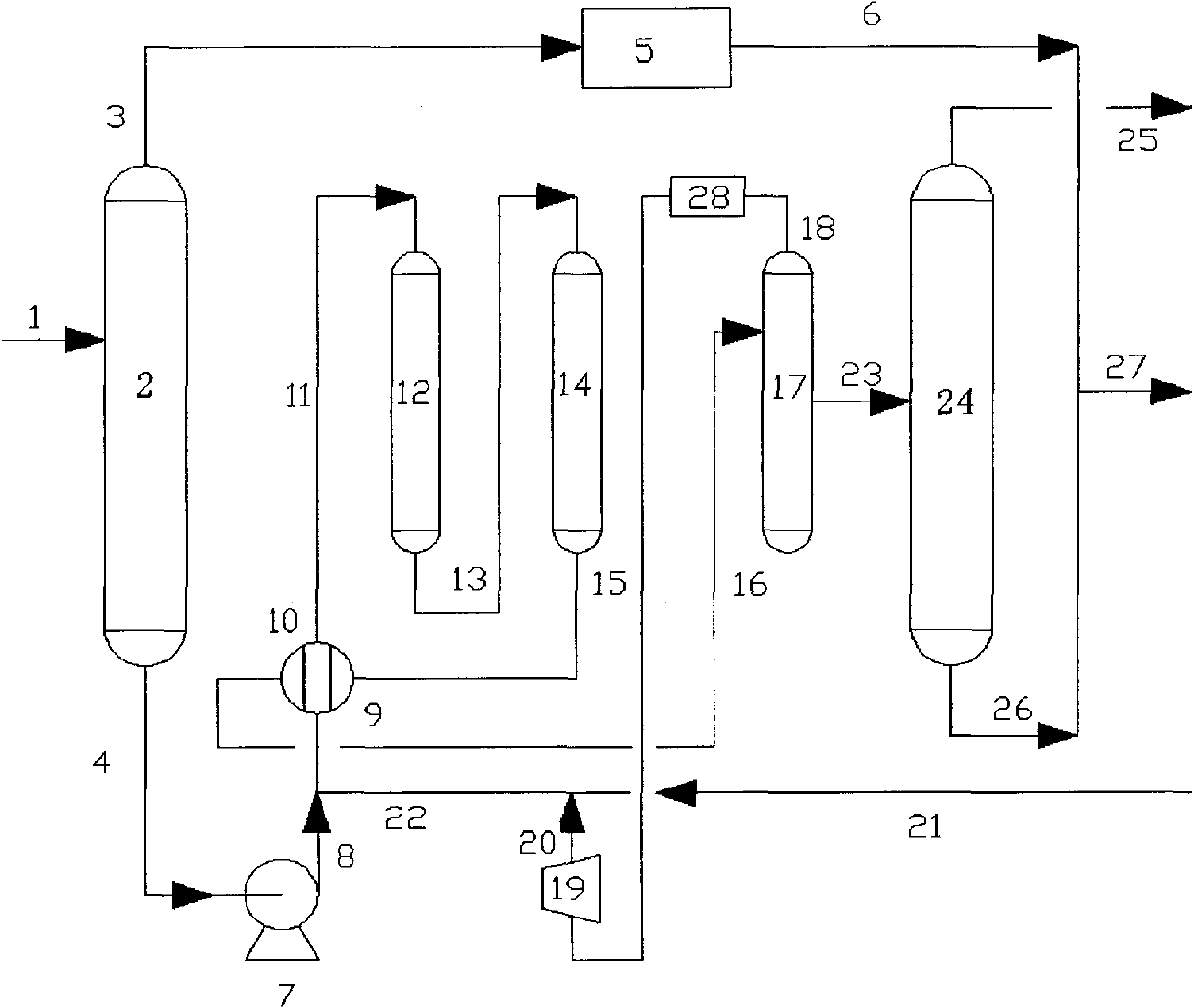

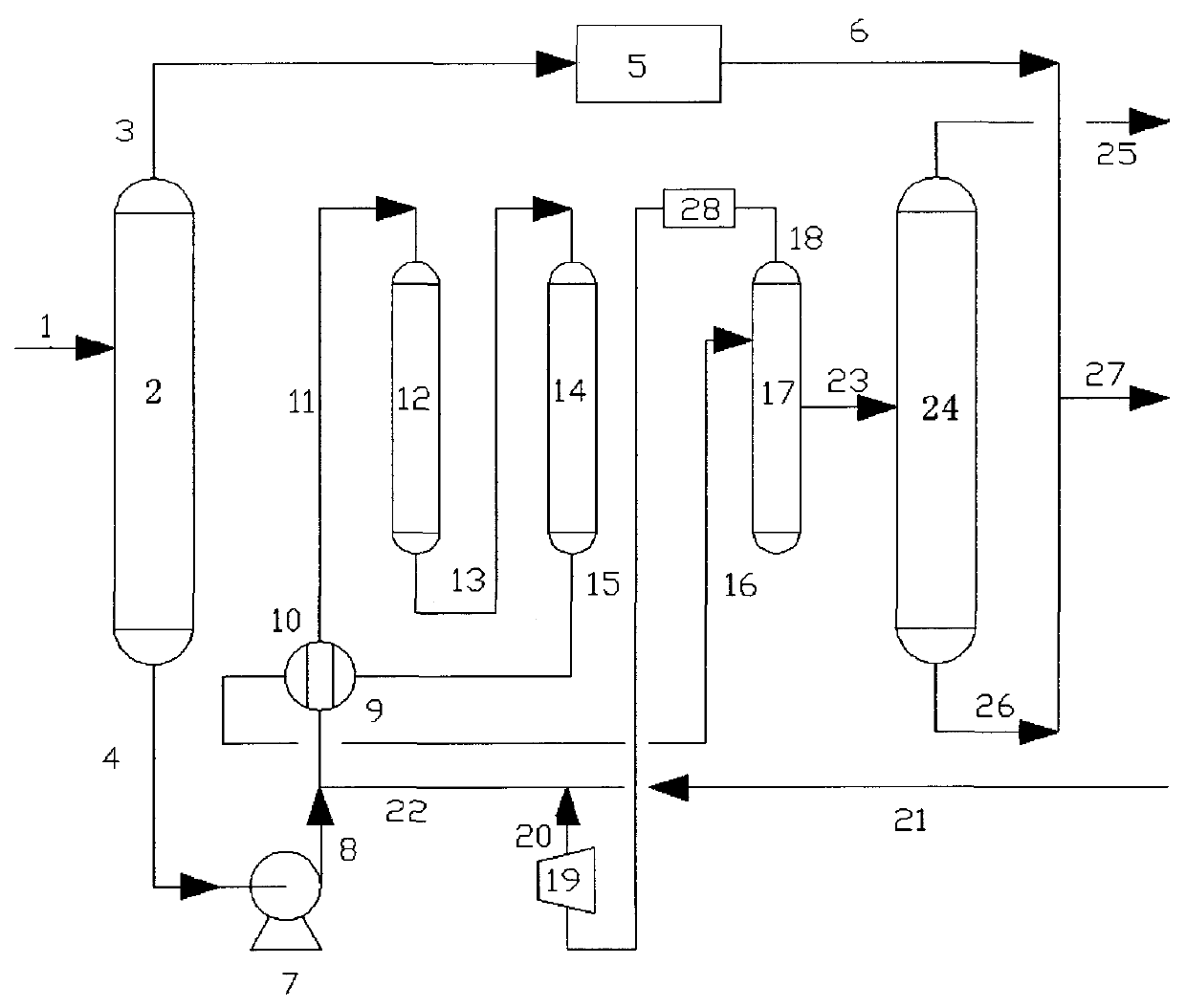

Process method for reducing olefins by hydrogen desulfurization of catalytic gasoline

A catalytic cracking gasoline and hydrodesulfurization technology, which is applied in the field of catalytic cracking gasoline hydrodesulfurization and olefin reduction, can solve the problems of difficult recovery, high sulfur content in gasoline, increased equipment investment, etc., and achieve the effect of stable operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Using FCC gasoline A as raw material, its properties are shown in Table 1. The raw material is first cut, the cutting point is 75°C, the heavy gasoline fraction and hydrogen are first contacted with the octane number recovery catalyst to react, the reaction effluent is blended with the sweetened light distillate oil to obtain gasoline products, and the octane number is recovered The process conditions and product properties are shown in Table 2.

Embodiment 2

[0046] Using FCC gasoline A as the raw material, after cutting according to the method described in Example 1, the heavy gasoline fraction, hydrogen, and octane number recovery catalyst and selective hydrodesulfurization agent are contacted to carry out octane number recovery and desulfurization reactions. Gasoline products were obtained by blending the upgraded oil and sweetened light distillate oil. The process conditions and product properties are shown in Table 2.

Embodiment 3

[0048] Using FCC gasoline A as the raw material, after cutting according to the method described in Example 1, heavy gasoline fractions, hydrogen and selective desulfurization agent are contacted for desulfurization reaction. The oil produced after desulfurization is blended with light distillate oil after sweetening to obtain gasoline products. The process conditions and product properties are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com