Modified ordered mesoporous organosilicon material, preparation method and application thereof

A mesoporous organosilicon and organosilicon technology, applied in chemical instruments and methods, other chemical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The PMO material is commercially available or can be prepared. The preparation of the PMO material can be carried out according to conventional methods in the art. For example, the preparation method of the PMO material can include: dissolving polyoxyethylene-polyoxypropylene-polyoxyethylene (P123) in an aqueous solution of potassium chloride , then add hydrochloric acid solution and the bridged silsesquioxane (such as 1,2-bistrimethoxysilylethane, BTME) in sequence, then stir and mix at 10-60°C for 1-30 minutes and stand for 5 -50 hours, then react in an autoclave at 80-120°C for 5-50 hours, collect the solid product after the reaction, and separate the PMO material from the solid product.

[0021] In the above method for preparing PMO materials, the weight ratio of the amount of P123 to the amount of bridged silsesquioxane can be 100:80-200, preferably 100:100-180, more preferably 100:130- 150.

[0022] In the above method for preparing PMO materials, the potassium ...

Embodiment 1

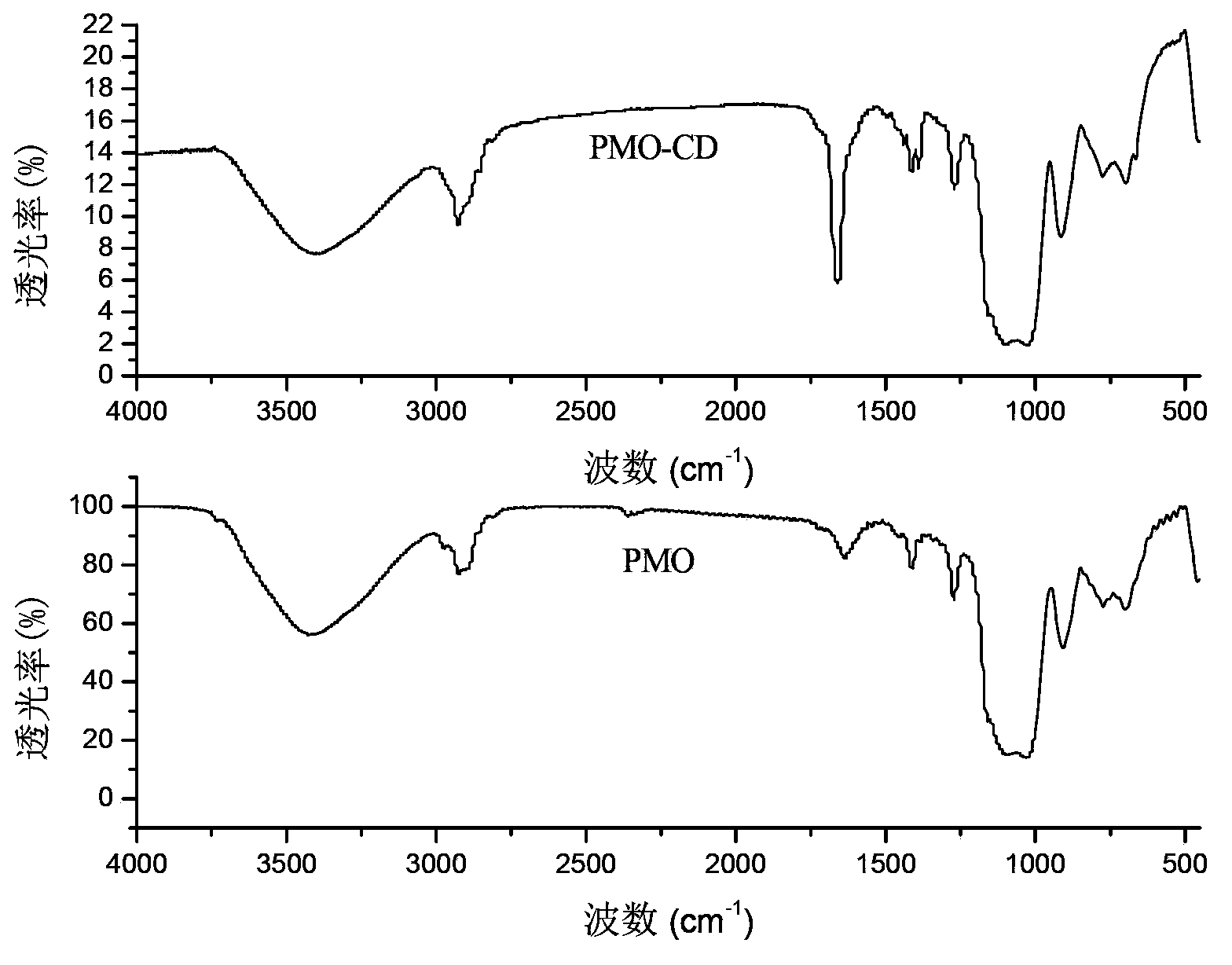

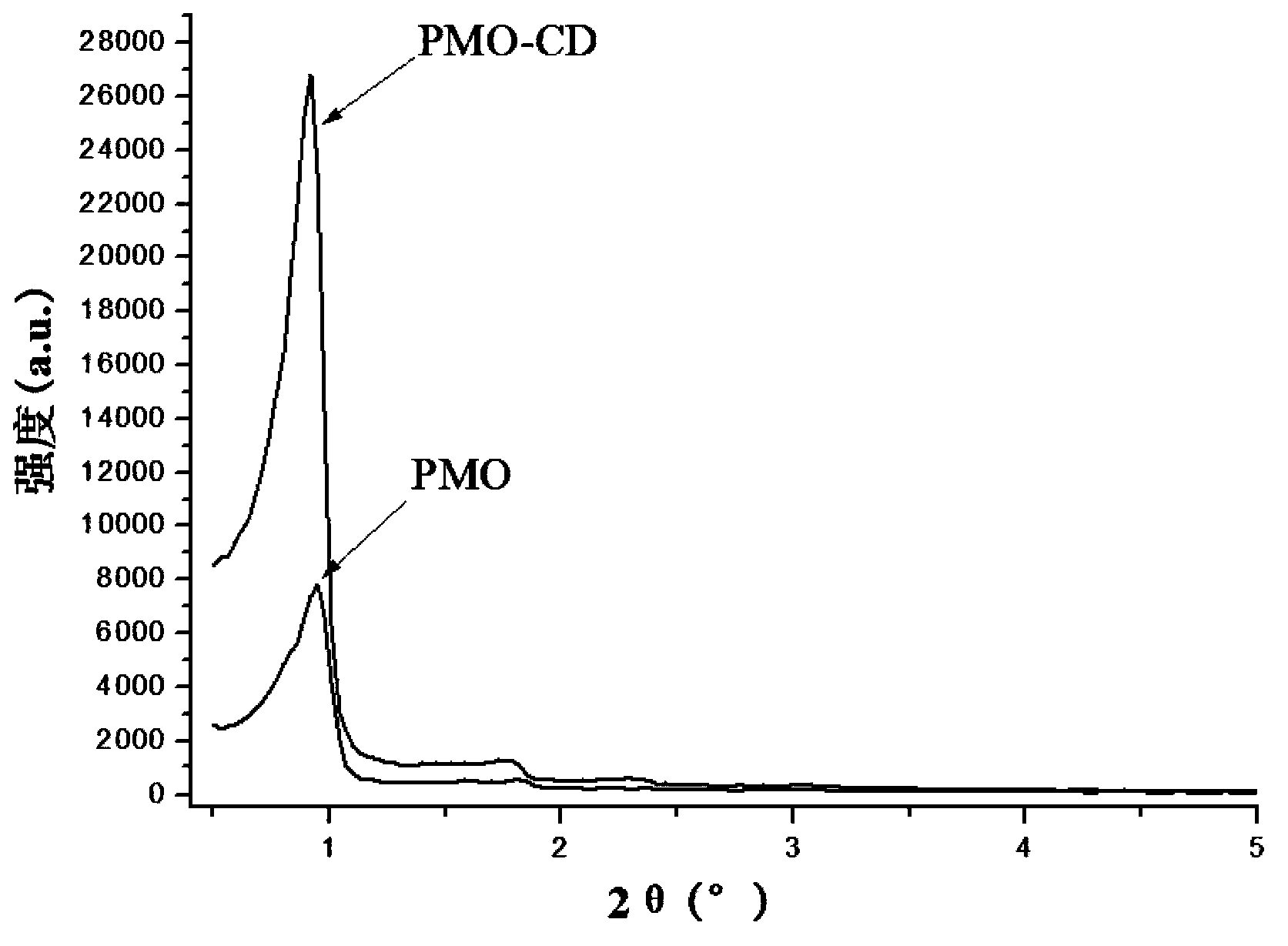

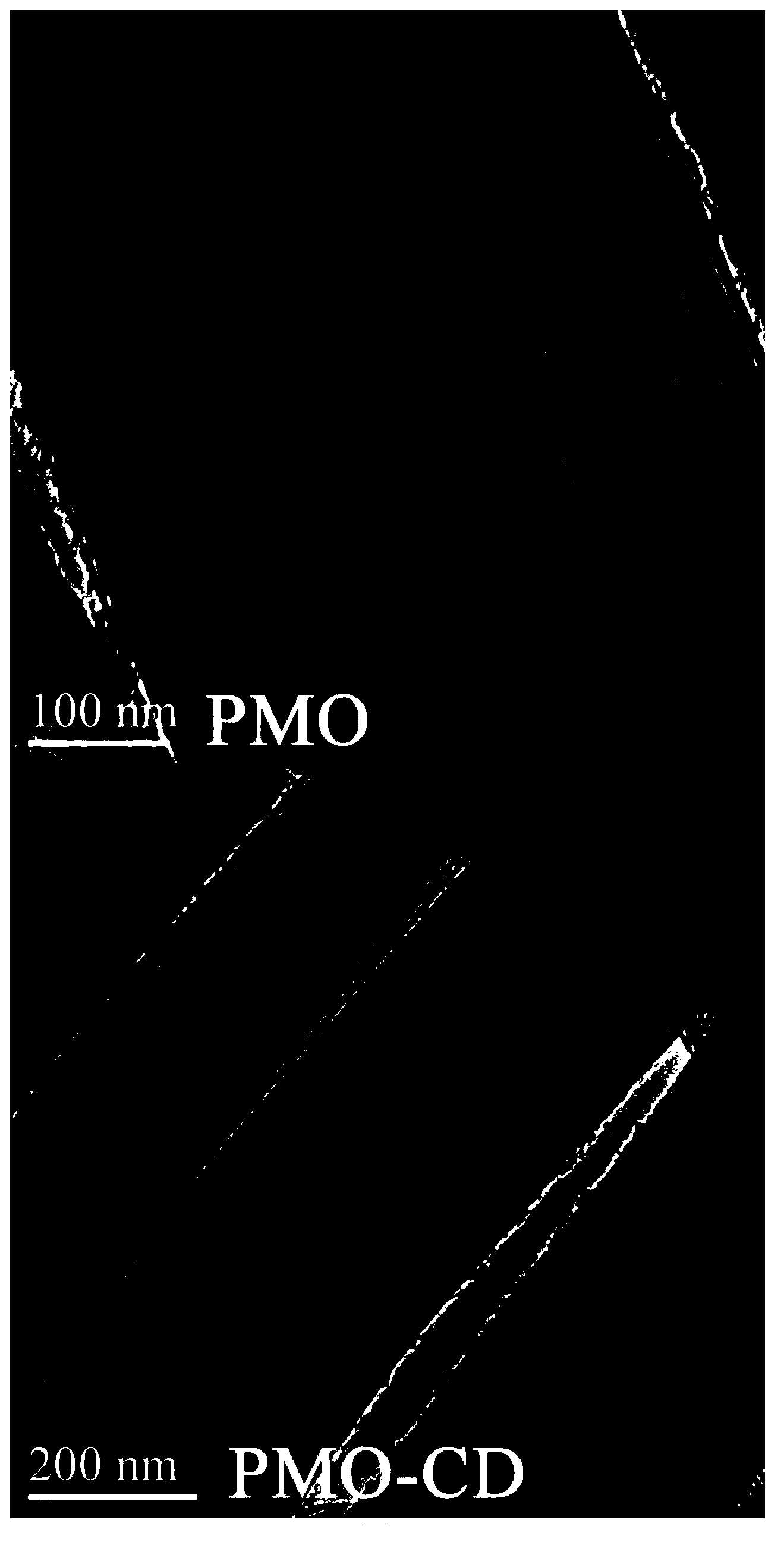

[0041] This example is used to illustrate the modified PMO material of the present invention and its preparation method.

[0042] At room temperature, add 5.74g of β-cyclodextrin (purchased from Tianjin Chemical Reagent Company, with a number average molecular weight of 1135) to 70ml of dry DMF, stir to dissolve it fully, and then add 3.70g of triethoxy (3-isocyanatopropyl) silicon (purchased from Bailingwei Technology Co., Ltd.), after mixing evenly, reacted at 70°C for 48 hours to obtain modified β-cyclodextrin.

[0043] Then, 0.38g of modified β-cyclodextrin was dissolved in 20ml of dry DMF, then 200mg of PMO material was added to the obtained solution, stirred to make it uniformly dispersed, and then added to the mixed system with a concentration of 0.1mol / L HCl solution to adjust the pH value of the mixed system to 2, and then slowly stir the reaction in a water bath at 30° C. for 24 h. After the reaction was completed, suction filtration was performed under reduced pres...

Embodiment 2

[0047] This example is used to illustrate the modified PMO material of the present invention and its preparation method.

[0048] At room temperature, add 5.74g of β-cyclodextrin (purchased from Tianjin Chemical Reagent Company, with a number average molecular weight of 1135) to 70ml of dry DMF, stir to dissolve it fully, and then add 3.70g of triethoxy (3-isocyanatopropyl) silicon (purchased from Bailingwei Technology Co., Ltd.), mixed evenly, and reacted at 60°C for 60 hours to obtain modified β-cyclodextrin.

[0049] Then, 0.38 g of modified β-cyclodextrin was dissolved in 20 ml of dry DMF, then 200 mg of PMO material was added to the obtained solution, stirred to make it uniformly dispersed, and then concentrated ammonia water was added to the mixing system to mix The pH value of the system was adjusted to 10, and then the reaction was stirred slowly in a water bath at 20° C. for 30 h. After the reaction was completed, suction filtration was performed under reduced pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com