Stirring type reaction kettle

A technology of reactor and stirring type, which is applied in the field of stirring reactor, and can solve the problems that the mixing and stirring effect cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

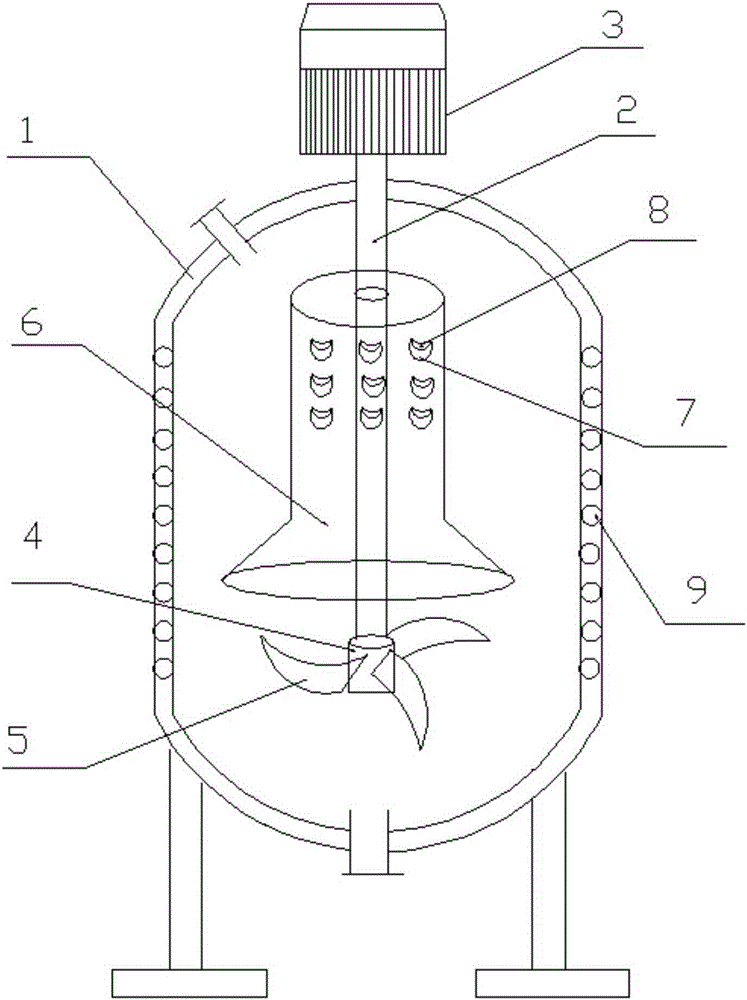

[0014] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0015] see figure 1 , a stirred reactor, comprising a cylinder 1, the cylinder is a double-layer structure, divided into inner and outer layers, a heat exchange tube 9 is coiled between the inner and outer layers, and the top of the cylinder is provided with a feed inlet , the bottom is provided with a discharge port, a stirring shaft 2 is installed in the cylinder, the top of the stirring shaft 2 is connected to the motor 3, the lower end is covered with a shaft sleeve 4, and 3 or 4 stirring blades 5 are evenly distributed along the circumference of the shaft sleeve , the root of the stirring paddle 5 is set at an angle of 30-45 degrees relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com