Kiln-opened flue gas treatment process in zinc-leaching residue volatilization kiln

A technology for zinc leaching slag and flue gas treatment, which is applied in the direction of gas treatment, process efficiency improvement, combined device, etc. It can solve the problems of failing to meet the waste gas emission standard, the difficulty of cleaning the dust in the smoke pipe, and affecting the cleanliness of the environment. Improved efficiency, good desulfurization and dust removal effect, and increased processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

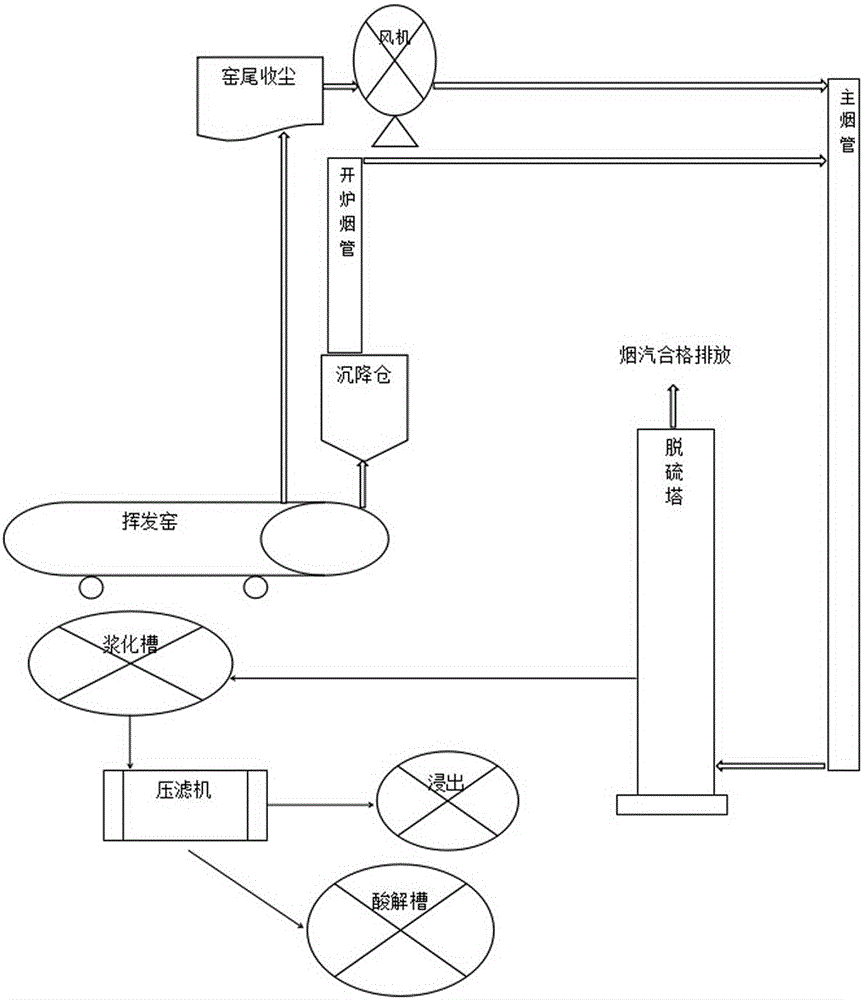

Image

Examples

Embodiment 1

[0025] A process for treating flue gas from a zinc leaching slag volatilization kiln, comprising the following steps:

[0026] (1) Preparation of volatilization kiln flue gas: volatilization kiln pyrometallurgy zinc leaching slag produces volatilization kiln flue gas with diesel flue gas, and the volatilization kiln uses coal gas as the main fuel in the heating stage and normal production stage. Diesel is the auxiliary fuel, and the weight ratio of gas to diesel is 110:15;

[0027] (2) Dedusting of flue gas from volatilization kiln: the flue gas from volatilization kiln prepared in step (1) is discharged into Flumes needle felt dust bag and settling bin for dust removal at the same time;

[0028] (3) Transmission of dust-removing gas from the dust-collecting bag at the kiln end: use a fan to convey the flue gas from the volatilization kiln that has been collected by the dust-collecting bag at the kiln end to the main flue pipe;

[0029] (4) Transmission of dedusting gas from ...

Embodiment 2

[0033] A process for treating flue gas from a zinc leaching slag volatilization kiln, comprising the following steps:

[0034] (1) Preparation of volatilization kiln flue gas: volatilization kiln pyrometallurgy zinc leaching slag produces volatilization kiln flue gas with diesel flue gas, and the volatilization kiln uses coal gas as the main fuel in the heating stage and normal production stage. Diesel is the auxiliary fuel, and the weight ratio of gas to diesel is 130:35;

[0035] (2) Dust removal of volatilization kiln flue gas: the volatilization kiln flue gas prepared in step (1) is simultaneously discharged into the glass fiber dust bag and the settling bin for dust removal;

[0036] (3) Transmission of dust-removing gas from the dust-collecting bag at the kiln end: use a fan to convey the flue gas from the volatilization kiln that has been collected by the dust-collecting bag at the kiln end to the main flue pipe;

[0037] (4) Transmission of dedusting gas from the sett...

Embodiment 3

[0041] A process for treating flue gas from a zinc leaching slag volatilization kiln, comprising the following steps:

[0042] (1) Preparation of volatilization kiln flue gas: volatilization kiln pyrometallurgy zinc leaching slag produces volatilization kiln flue gas with diesel flue gas, and the volatilization kiln uses coal gas as the main fuel in the heating stage and normal production stage. Diesel is the auxiliary fuel, and the weight ratio of gas to diesel is: 120:25;

[0043] (2) Dust removal of volatilization kiln flue gas: the volatilization kiln flue gas prepared in step (1) is simultaneously discharged into the glass fiber dust bag and the settling bin for dust removal;

[0044] (3) Transmission of dust-removing gas from the dust-collecting bag at the kiln end: use a fan to convey the flue gas from the volatilization kiln that has been collected by the dust-collecting bag at the kiln end to the main flue pipe;

[0045] (4) Transmission of dedusting gas from the settl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com