Large boiler low-temperature flue gas purification waste heat drying bed

A low-temperature flue gas, large boiler technology, applied in heating to dry solid materials, hearth furnaces, drying solid materials, etc., can solve the problems of increased exhaust gas temperature, low utilization rate of flue gas waste heat, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

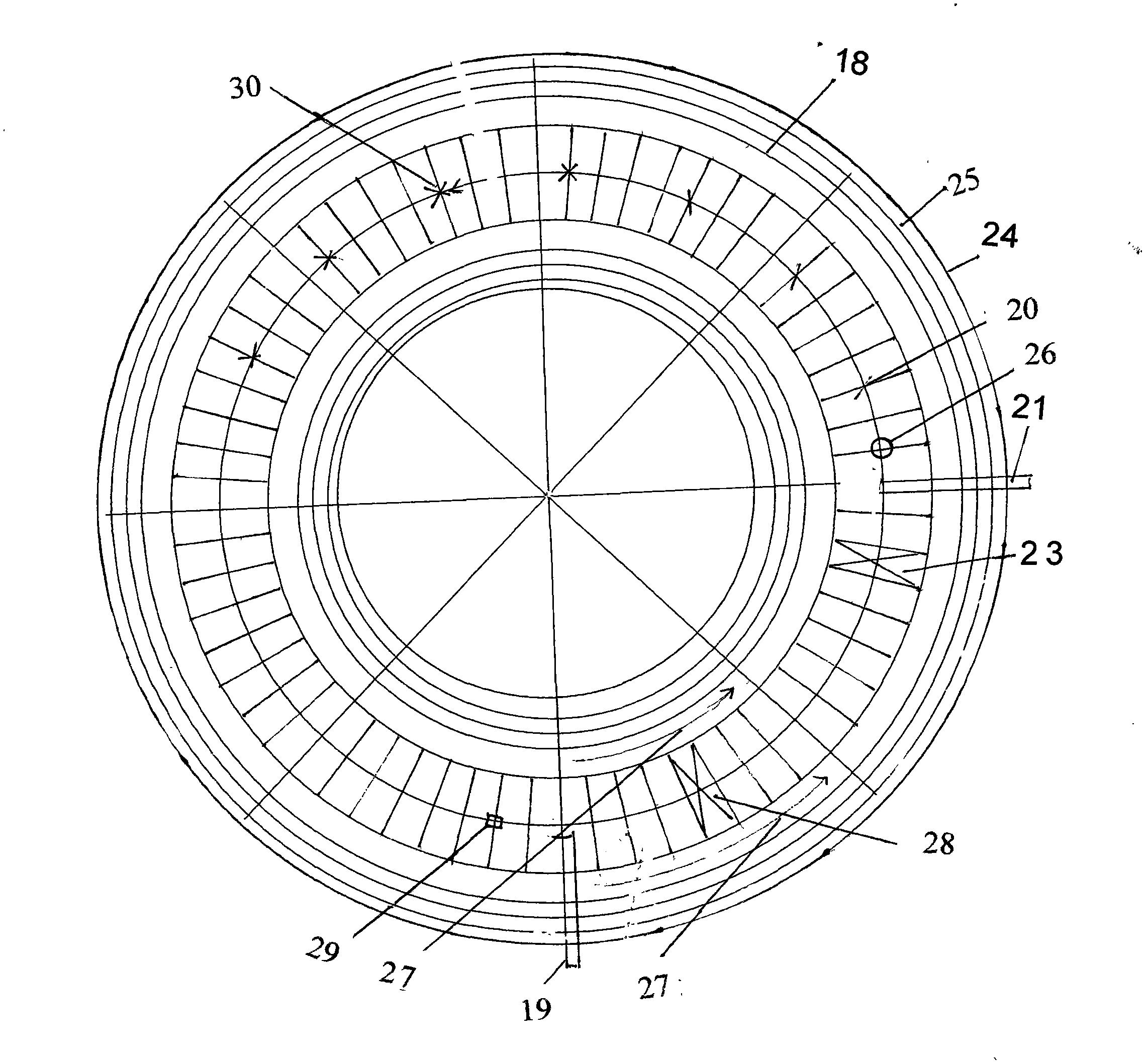

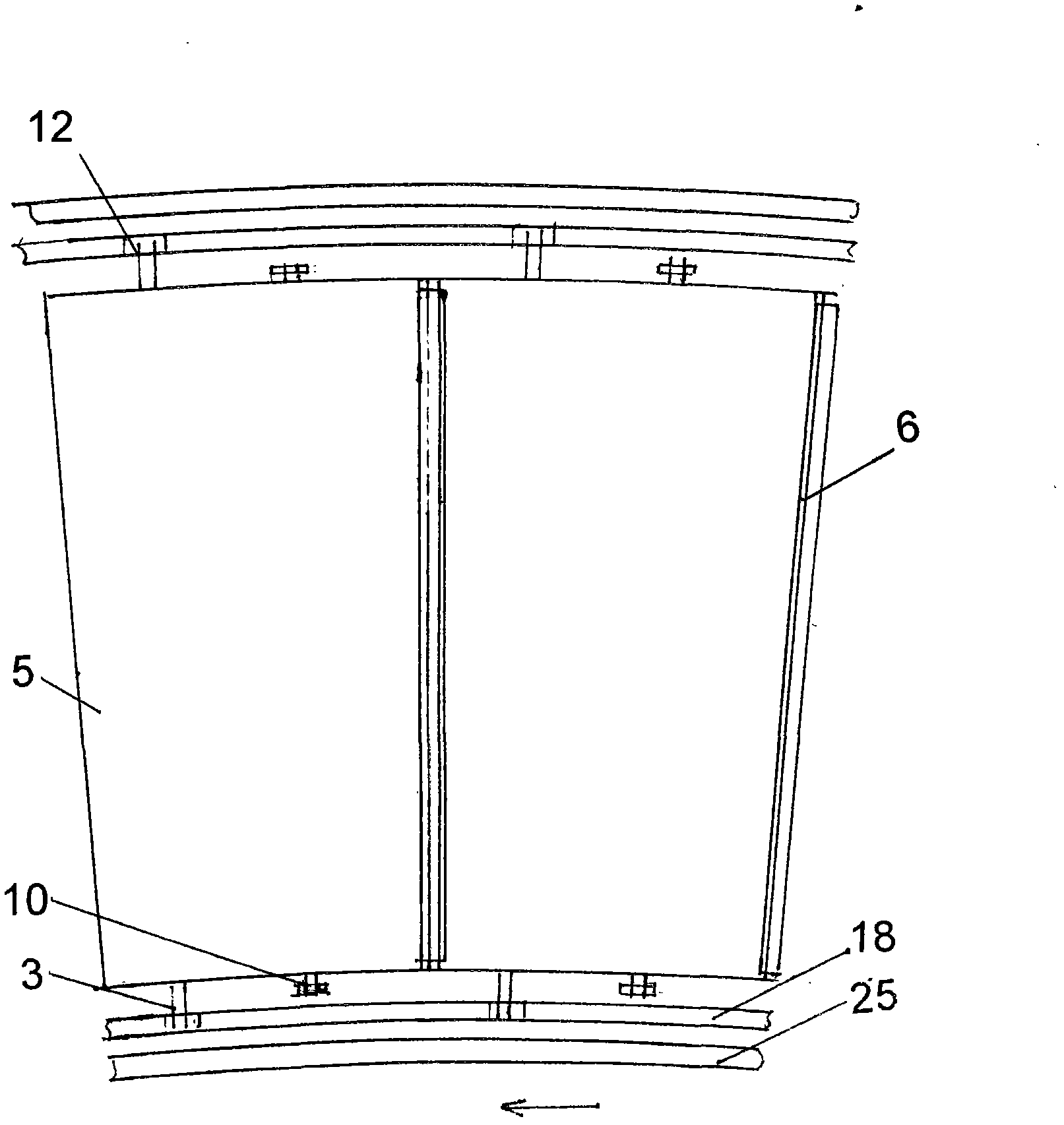

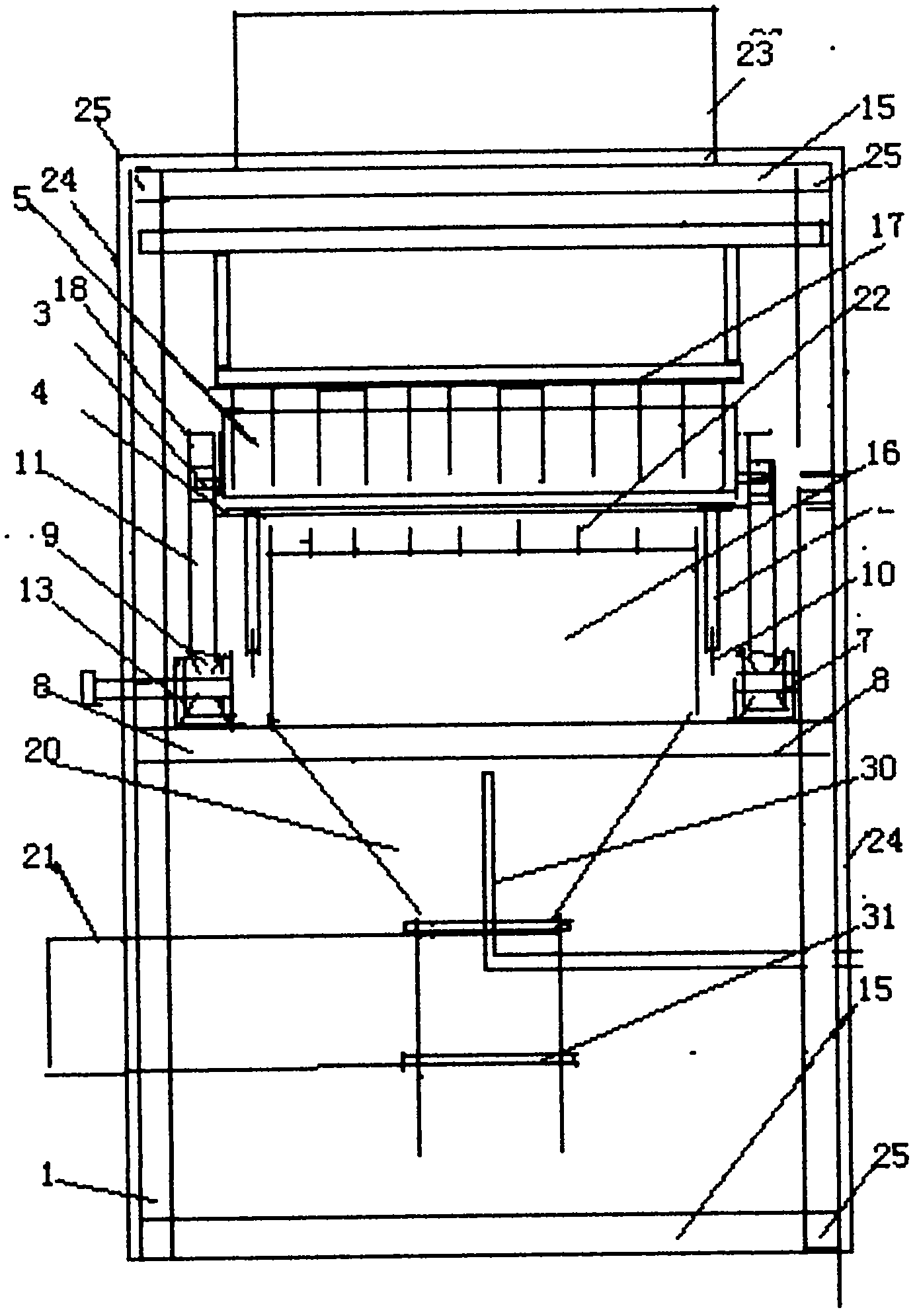

[0013] The working process of the large-scale boiler flue gas purification low-temperature waste heat drying bed of the present invention will be further explained below according to the accompanying drawings. The waste heat is transferred to the hopper through the flue fins, and the dried material gradually reaches the drying standard by absorbing heat and raising the temperature to evaporate water vapor. Then in the unloading area, the unloading is completed by the ring self-unloading device and enters the next process. The disc harrow installed above the frame can stir and stir the materials, prevent viscous materials from agglomerating during the drying process and expand the area of dried materials. The evaporative exhaust pipe and the subsidized cold wind form a convective flow, which not only accelerates the heat release speed of the low-temperature flue gas, but also accelerates the evaporation of material moisture. The sulfur dioxide in the flue gas is deposited in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com