A swirl coupling deep desulfurization strengthening module

A deep desulfurization, swirling plate technology, applied in chemical instruments and methods, using liquid separating agents, gas treatment, etc., can solve the problems of large flow rate through the plate, increased flue gas resistance, low opening rate, etc. Liquid mass transfer rate, improving gas-liquid contact time, preventing scaling or clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

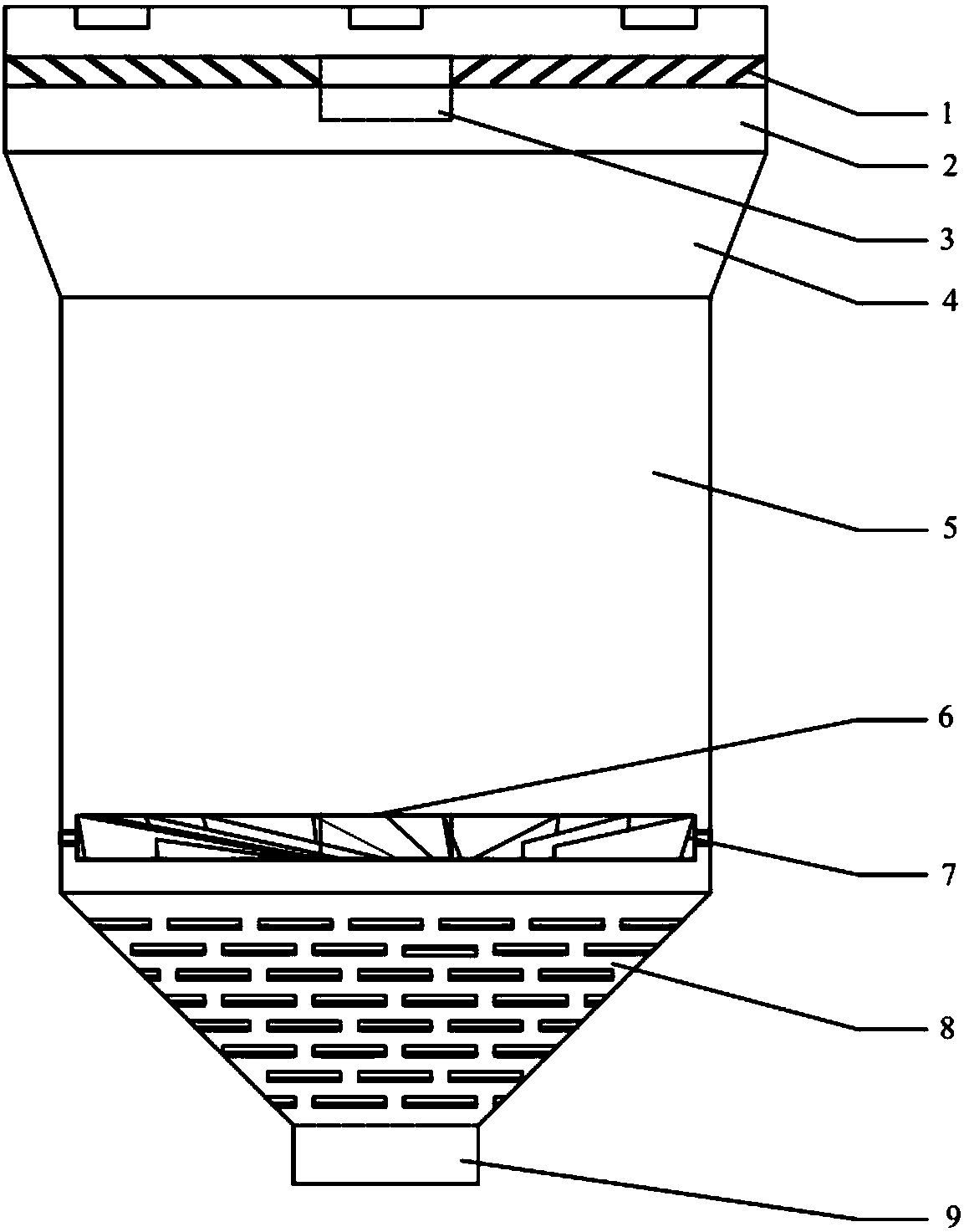

[0041] Such as figure 1 As shown, a swirl coupled deep desulfurization module is arranged at the lower part of the spray layer of the desulfurization tower, including an outer cylinder with open upper and lower ends and a slit cone arranged in the outer cylinder from bottom to top. Bottom cover 8, outward jet swirl plate 7 and inward jet manifold 1, the side wall of slit conical bottom cover 8 is provided with the slit mouth 14 that passes through for air flow, and the center of outward jet swirl plate 7 is provided with blind plate 6, the center of the inward jetting manifold 1 is provided with a downcomer 3 that guides the desulfurization liquid to the blind plate 6, and the bottom of the slit conical bottom cover 8 is also provided with a conical bottom cover downcomer 9; In this state, the desulfurization liquid sprayed from the spray layer onto the inward jet manifold 1 is sprayed centripetally, and the desulfurization liquid converges to the center of the inward jet mani...

Embodiment 2

[0054] In this embodiment, the elevation angle between the inward blades 11 in the inward jet manifold 1 and the horizontal plane is 28°, the aperture ratio is 30%, and the elevation angle between the jet blades in the outward jet swirl plate 7 and the horizontal plane is 30°. The porosity is 35%. All the other are with embodiment 1.

[0055] For a coal-fired boiler with an evaporation capacity of 30t / h, the designed flue gas volume is 85,000m 3 / h, the flue gas temperature is 150°C, and the sulfur dioxide concentration in the inlet flue gas reaches 3500mg / Nm 3 . The module of this embodiment is added, the inner diameter of the desulfurization tower is 2500 mm, and the flue gas desulfurization process of limestone-gypsum method is adopted. When the boiler load is 90%, the liquid-gas ratio is 1.8L / m 3 The measured desulfurization efficiency is 99.5% (the concentration of sulfur dioxide in the outlet flue gas is lower than 30mg / Nm 3 ), the airflow resistance of the whole to...

Embodiment 3

[0057] In this embodiment, the outer cylinder is composed of an upper cylinder 2 with a regular octagonal cross-section, a cylindrical lower cylinder 5, and a transition pipe 4 arranged between the upper cylinder 2 and the cylindrical lower cylinder 5, wherein, The diameter of the circumscribed circle of the regular octagon is 1500mm.

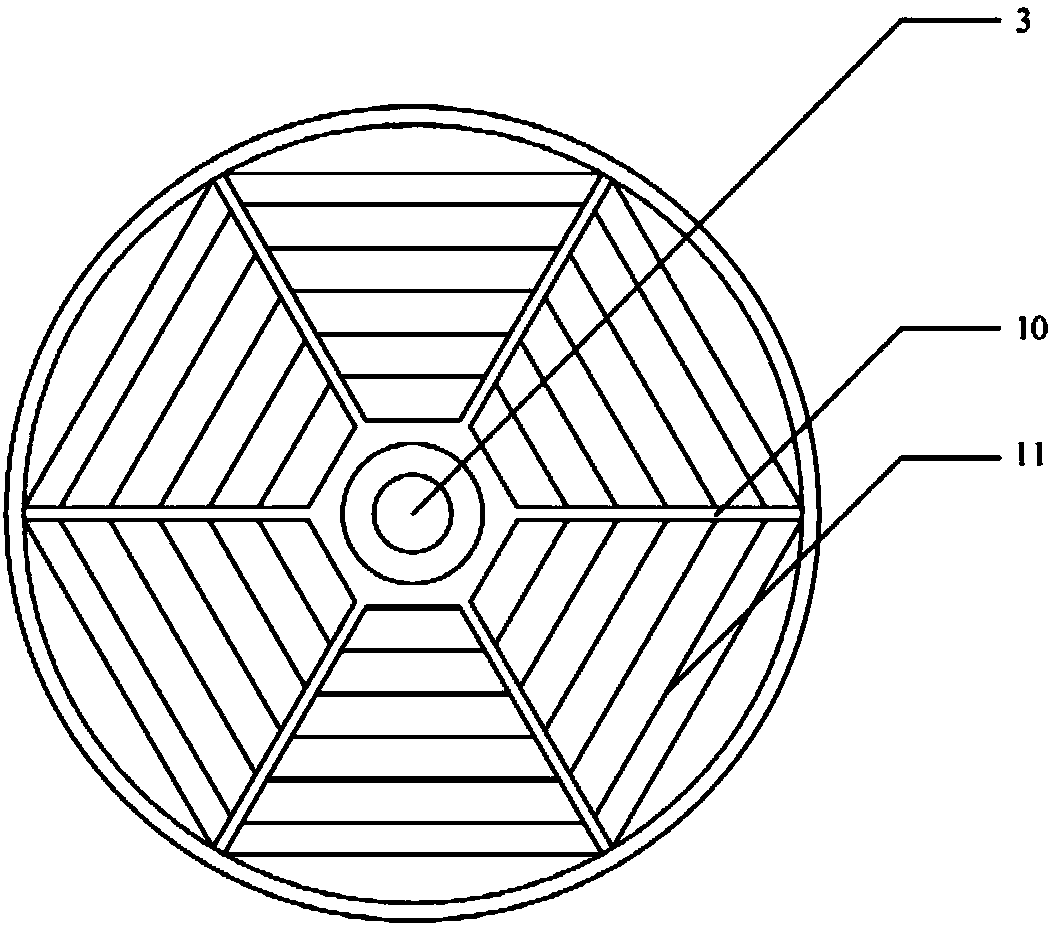

[0058] In the inward jet manifold 1, there are 56 inward blades 11 in total, which are divided into 7 layers obliquely in the form of a regular octagon. The elevation angle between the inward blades 11 and the horizontal plane is 40°, and the width is 120mm. The width is 120mm.

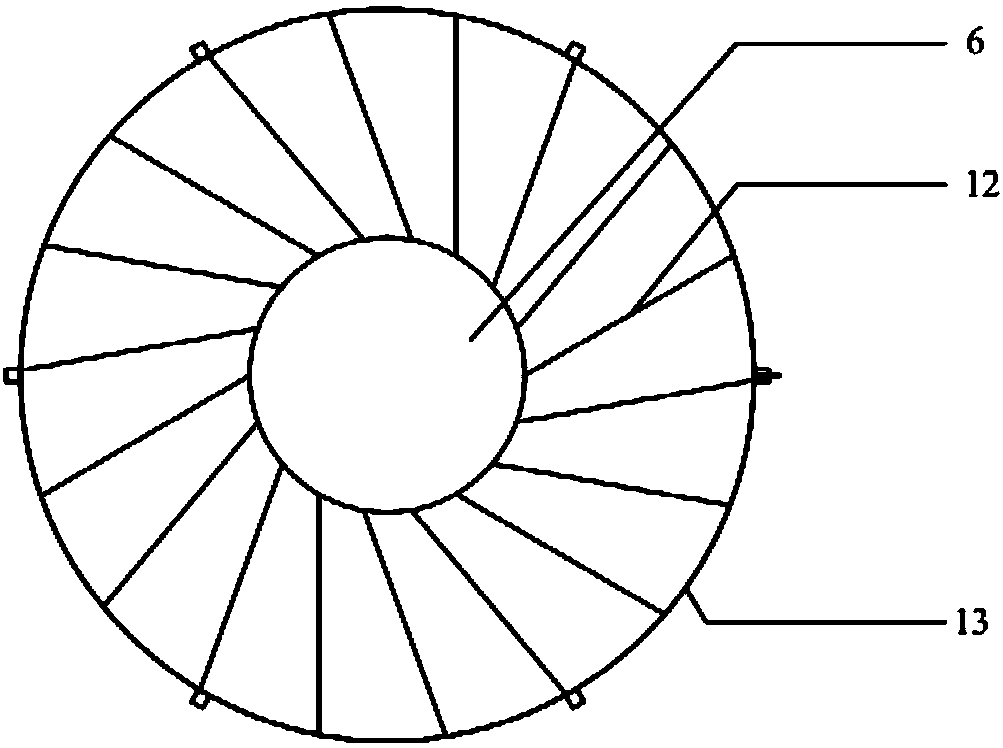

[0059] The plurality of injection blades 12 in the outward injection swirl plate 7 are fan-shaped and obliquely fixed one by one, and the line between the center of the injection blade 12 and the center of the circle of the second support rib 13 is 60° with the injection blade 12. And the elevation angle between the spray blade 12 and the horizontal plane is 40°. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com