Special tail gas desulfurization and dust removal equipment for tobacco drying and baking barn

A desulfurization and dust removal equipment, desulfurization and dust removal technology, applied in the direction of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of excessive combustion exhaust emissions, unfavorable energy saving and environmental protection, etc., and achieve the effect of low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

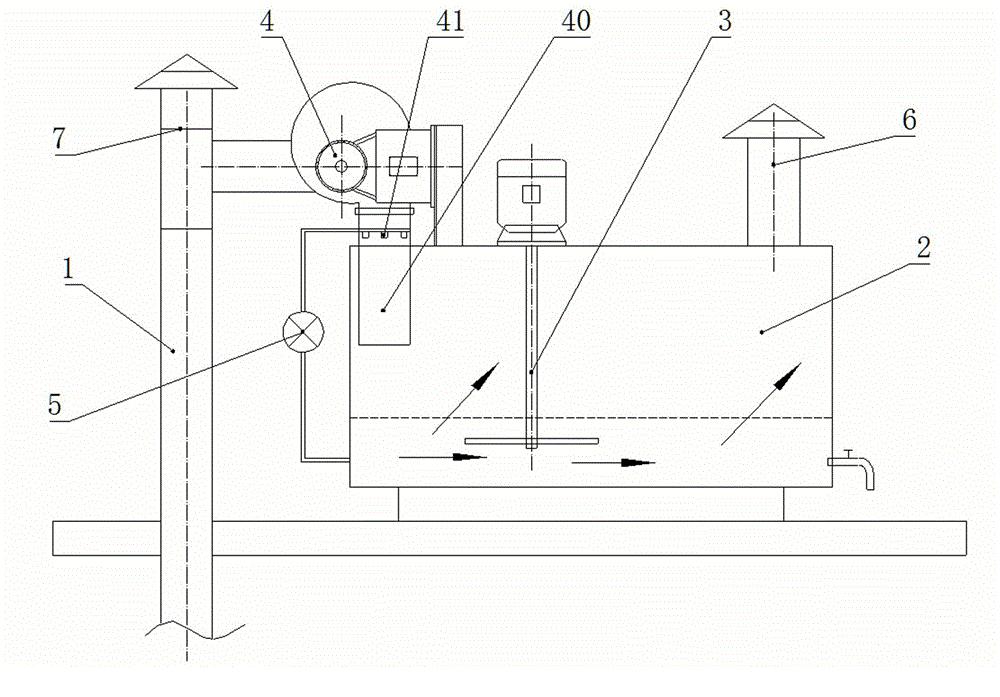

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] like figure 1 It can be seen that the exhaust gas desulfurization and dust removal equipment dedicated to tobacco drying and curing barns of the present invention includes a chimney 1, which is connected to the hot blast stove of the curing barn.

[0015] It also includes a desulfurization and dust removal box 2 and an agitator 3, the stirring paddle of the agitator 3 extends below the liquid level of the desulfurization and dust removal box 2; the desulfurization and dust removal box 2 should be filled with purified liquid, and in this embodiment, the purified liquid is lime water.

[0016] An induced draft fan 4 is arranged between the chimney 1 and the desulfurization and dust removal box 2, and a plurality of nozzles 41 are arranged in the outlet duct 40 of the induction fan 4, and between the described desulfurization and dust removal box 2 and the pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com