Dust removal and desulphurization device of roasting kiln

A desulfurization device and kiln technology, applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of short collision time, insufficient affinity, unfavorable promotion, etc., and achieve convenient maintenance and easy The effect of less damage parts and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

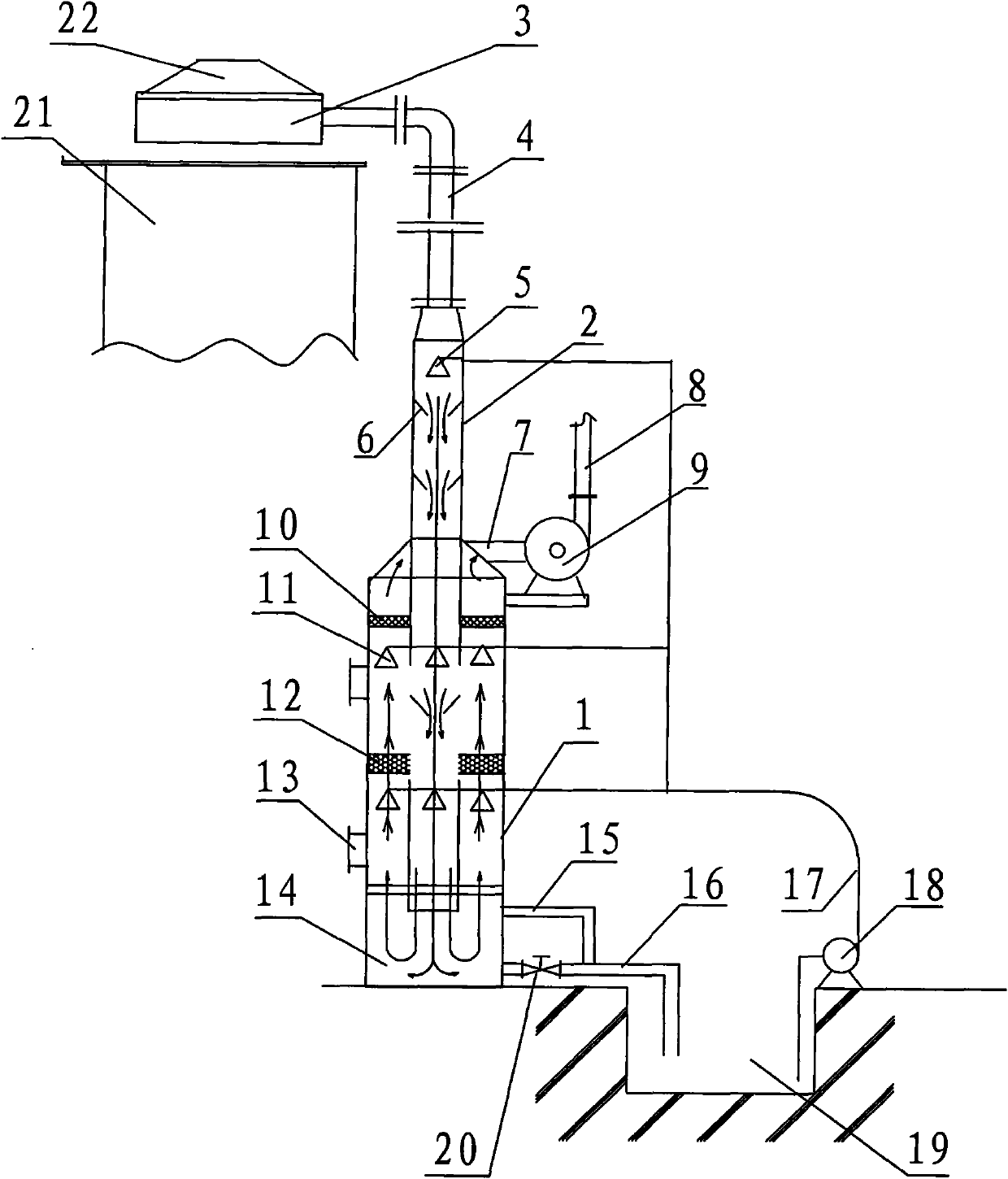

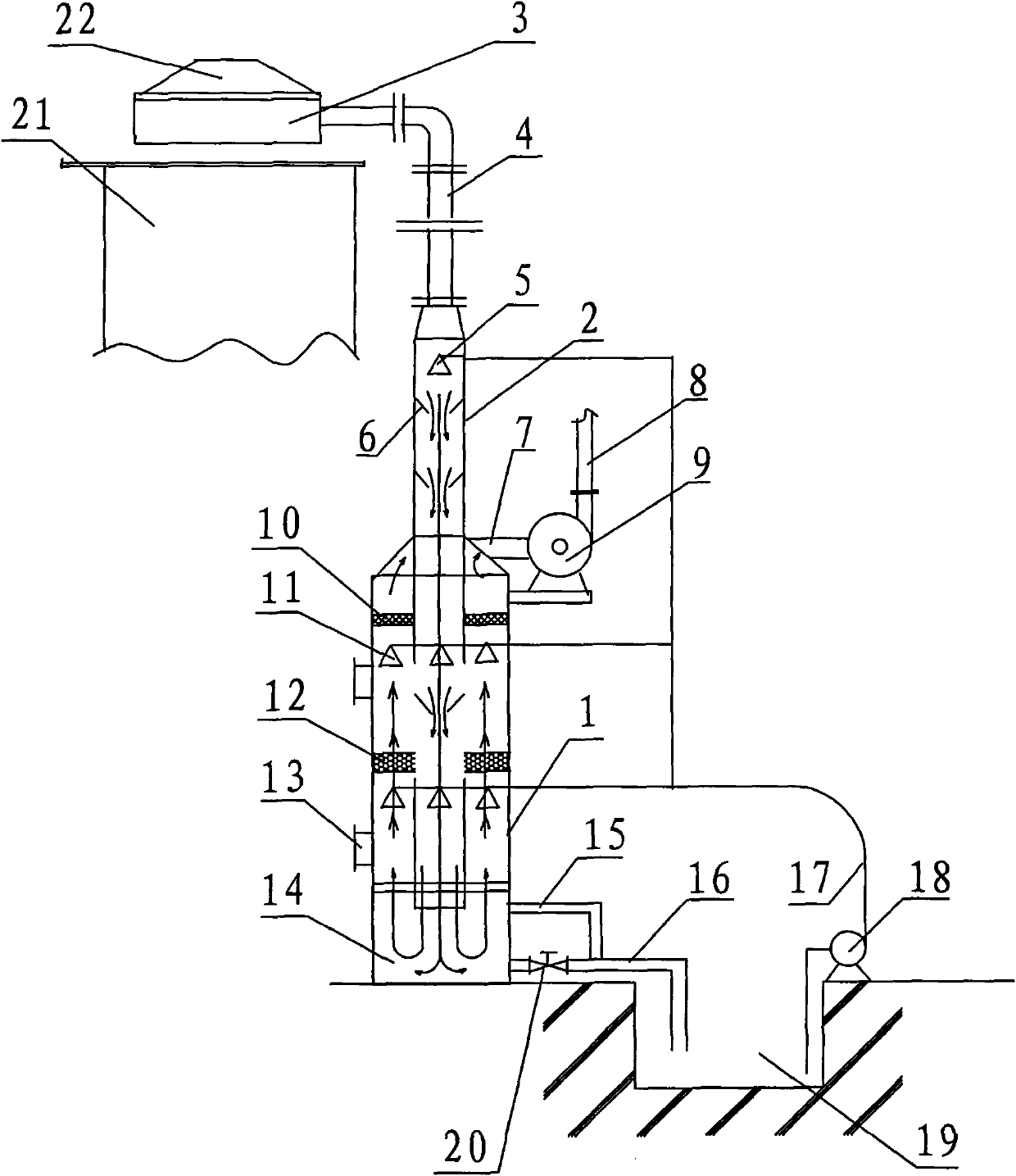

[0010] The dedusting and desulfurization device of the roasting kiln includes a flue gas dust removal tower 2, a desulfurization tower 1, a circulation neutralization tank 19, an overflow pipe 15, a slag discharge pipe 16, a fan 9, a high-pressure circulation pump 18 and an annular dust collection hood 3. The upper part of the desulfurization tower 1 is provided with a net gas discharge port 7, and the outer wall is provided with a maintenance hole 13, and the lower part of the desulfurization tower 1 is provided with an impact water bath 14. The upper part of the flue gas dedusting tower 2 is provided with a central spray head 5, and three inverted conical liquid collecting plates 6 are provided in the tower. Shock water bath 14 inside. The upper and lower parts between the inner wall of the desulfurization tower 1 and the outer wall of the flue gas dedusting tower 2 are respectively equipped with a liquid-gas separator 10 and a packing layer 12, and an outer circular spray h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com