Fire coal gasfication atmospheric water heating horizontal boiler

A horizontal boiler, atmospheric pressure technology, applied in the field of boilers, can solve problems such as low combustion efficiency and air pollution, and achieve the effects of improving efficiency, eliminating hidden dangers and achieving obvious effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

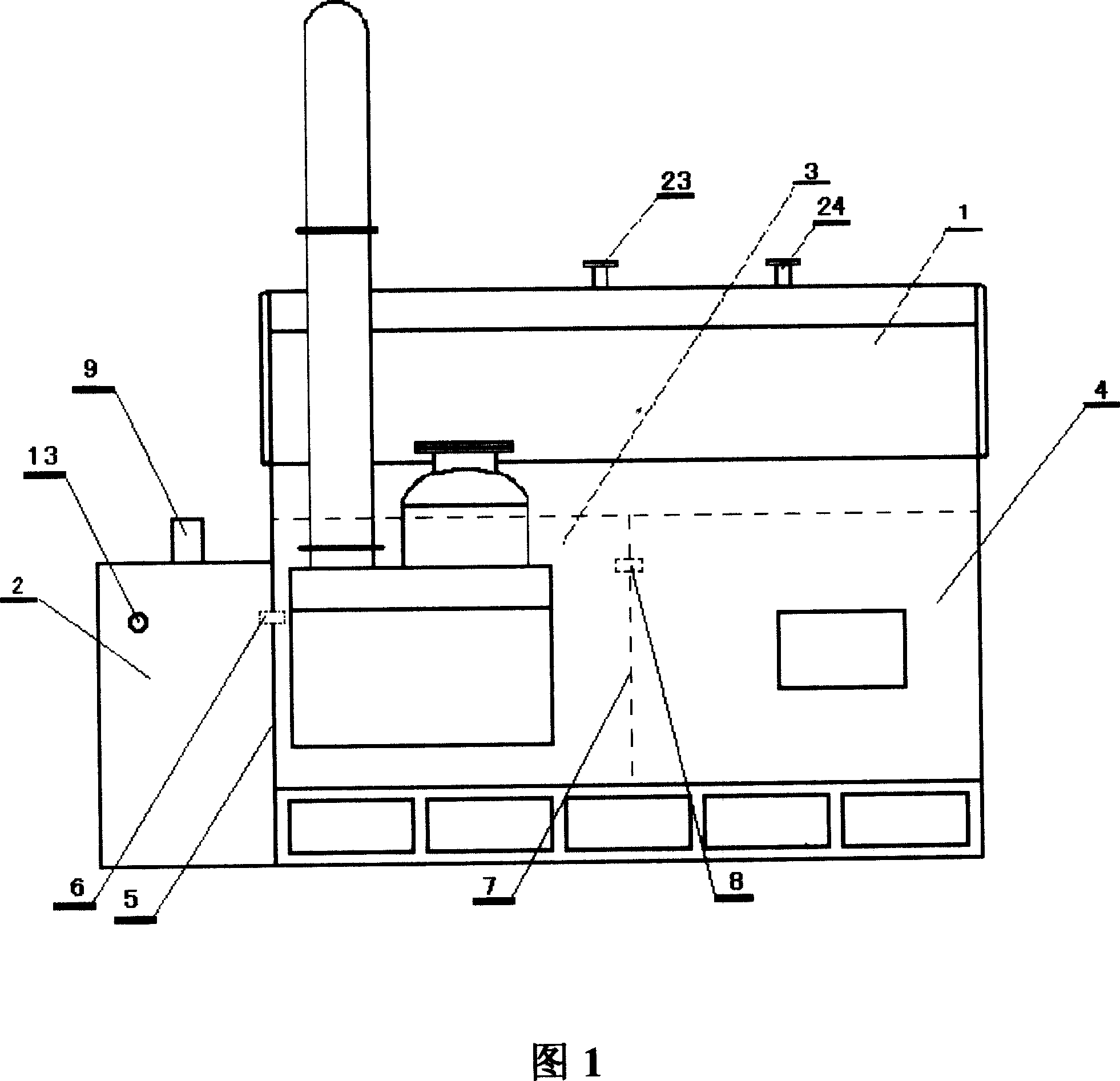

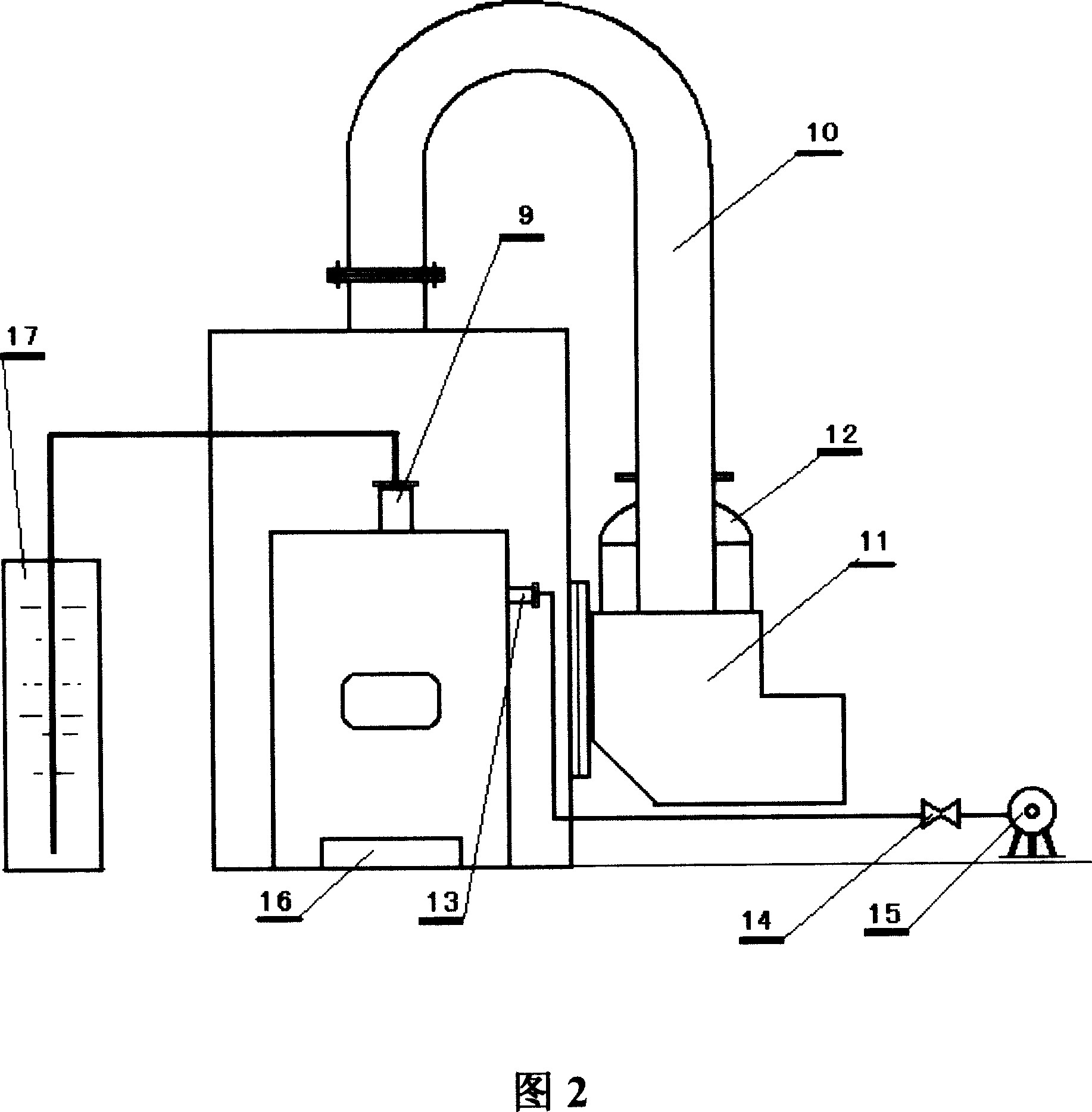

[0016] Coal-fired gasification atmospheric pressure hot water horizontal boiler, including furnace body 1, gas generation area 2, open flame ignition area 3, anti-explosion device, air induction device, blast device, desulfurization and dust removal device. The top of the furnace body 1 is equipped with a water outlet 23 and an air communication port 24, and a water-sealed closed slag cleaning pool 16 is arranged at the bottom of the furnace body. The front part outside the furnace body 1 is provided with a gas generating area 2, and an open flame ignition area 3 is provided in the hearth of the furnace body 1, and a closed isolation arch 5 is installed in the middle of them, and one or two smoke combustion holes are arranged on it. 6. The coal gas generated in the gas generation area 2 is sent to the open flame ignition area 3 through the combustion hole 6 . The open flame ignition area 3 is placed on the furnace front and is isolated from the combustion chamber 4 by an isola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com