Multistage rotation impact wet desulfurizing and dust-removing equipment

A wet desulfurization and dust collector technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of low desulfurization and dust removal efficiency, and achieve the effects of simple maintenance, good effect and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

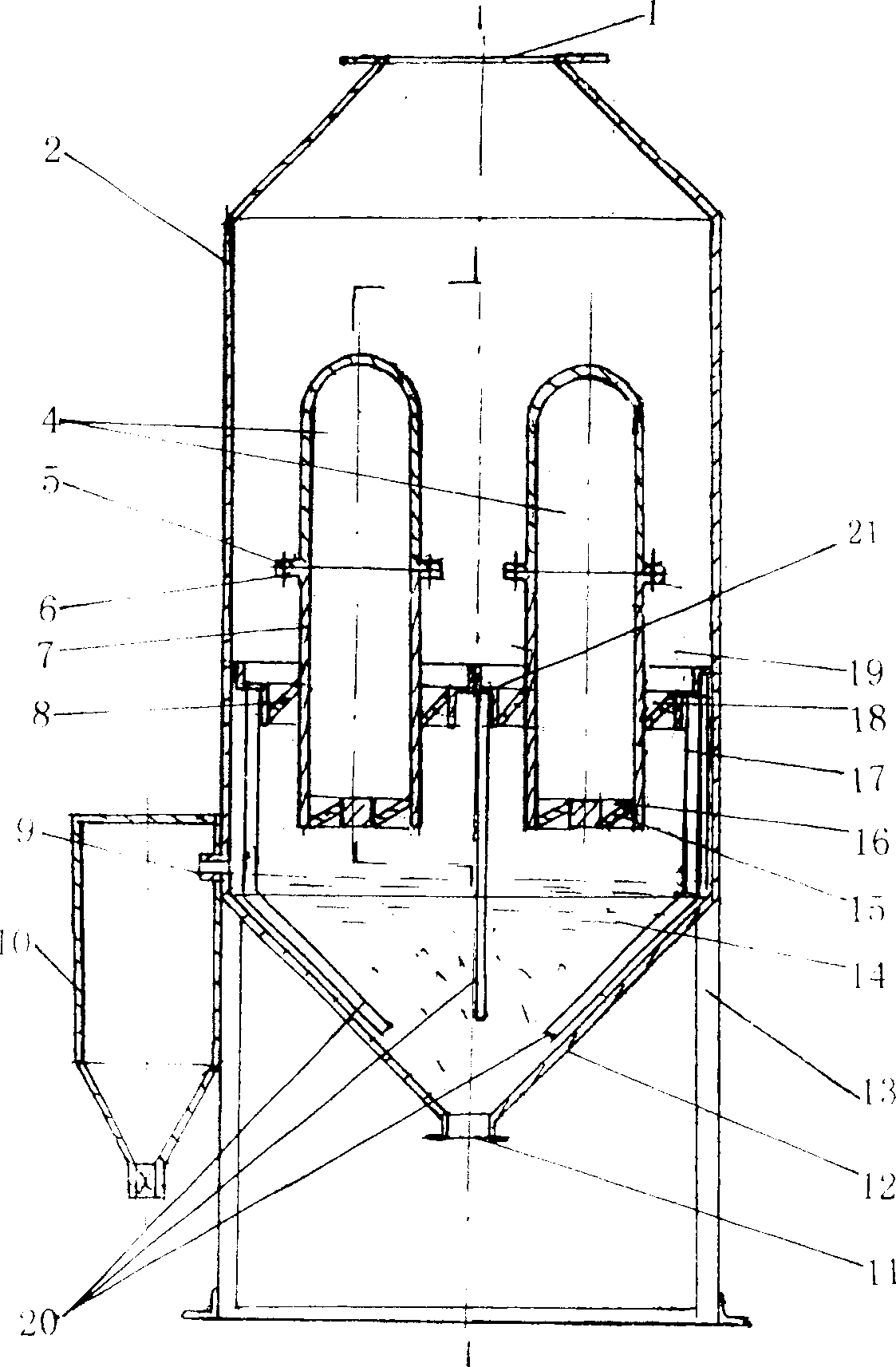

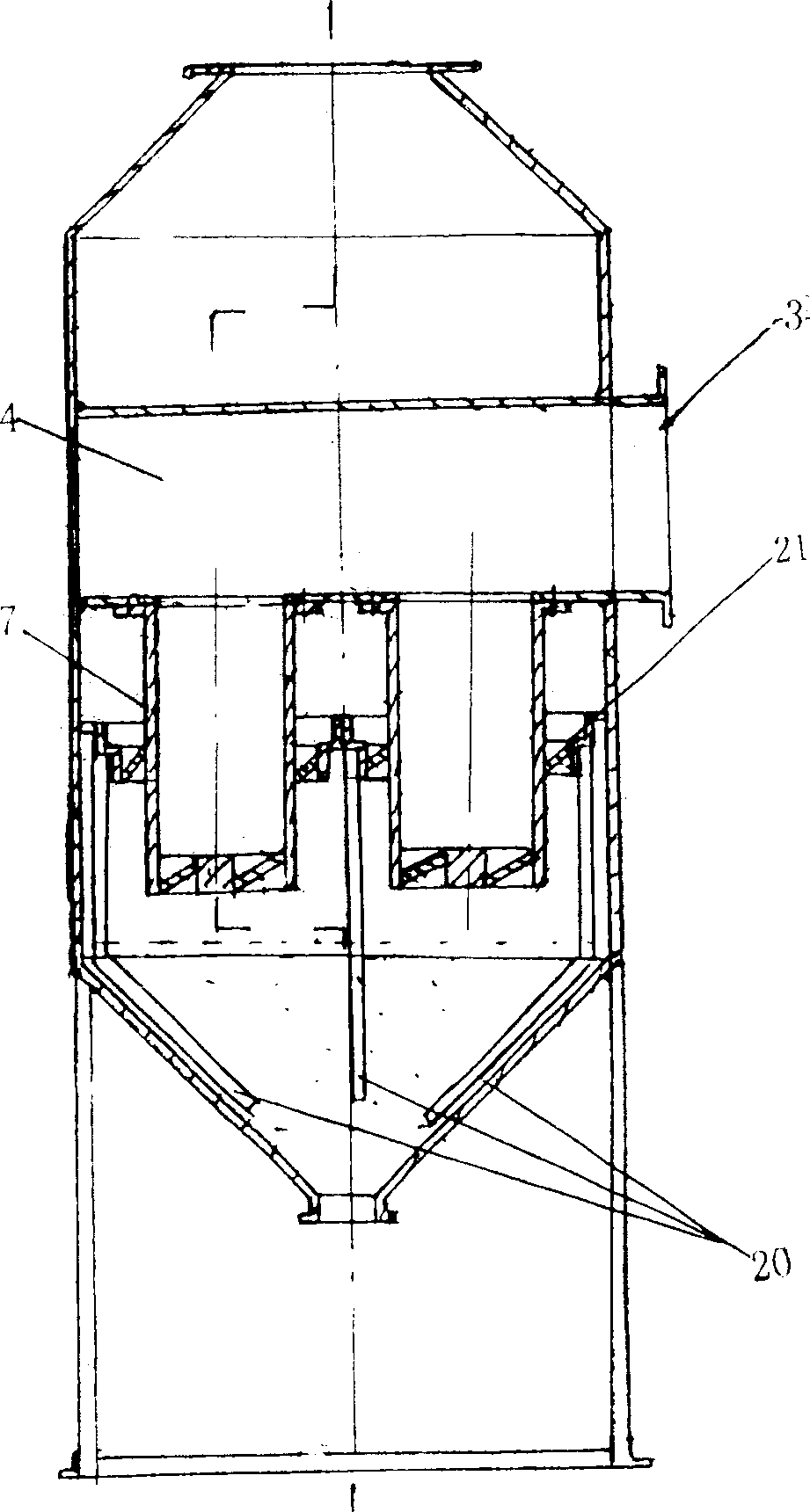

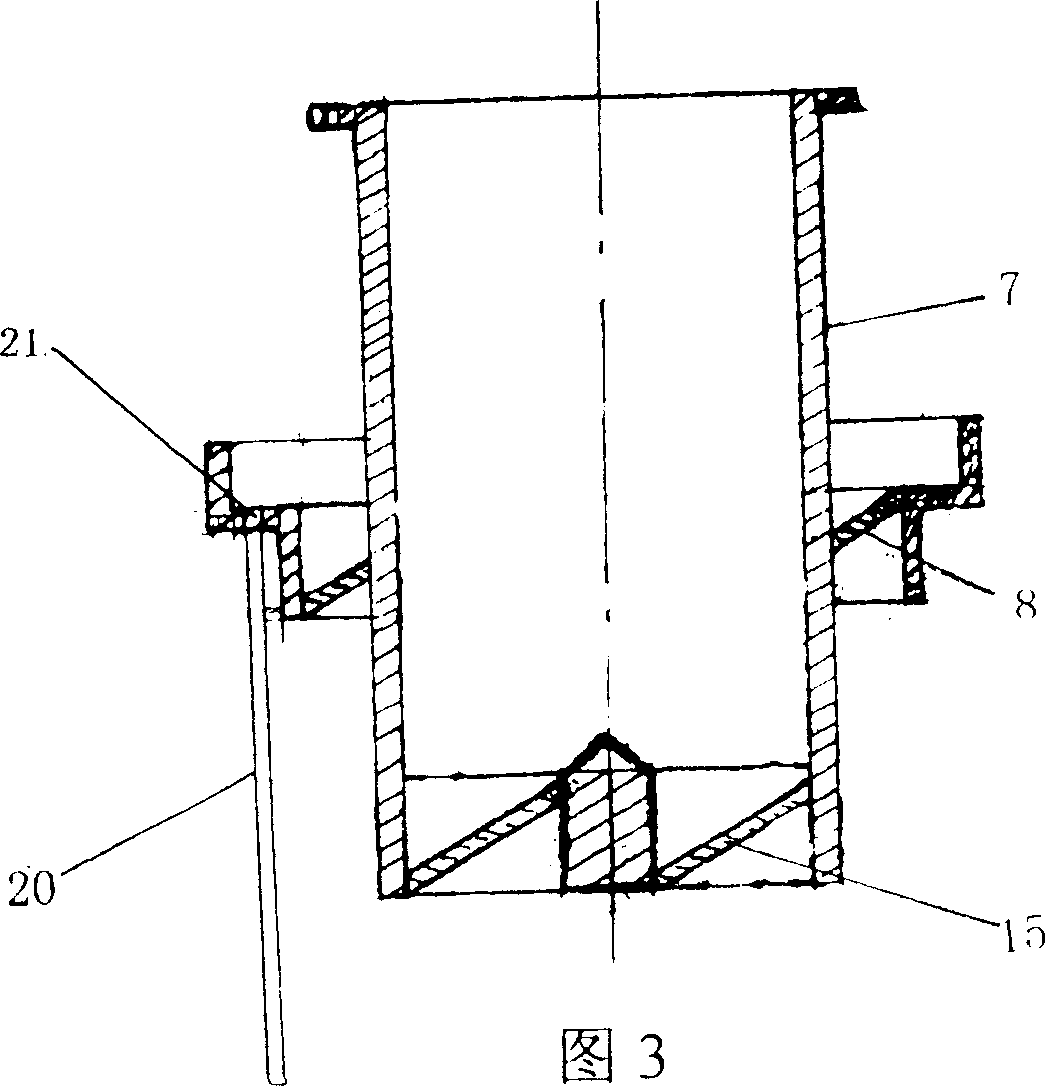

[0010] Such as figure 1 As shown, the multi-stage rotary impact wet desulfurization dust collector of the present invention includes a housing 2, a bracket 13, a flue gas inlet 3, a flue gas channel 4, a multi-stage cyclone pipe 7, and a dust gas diffusion rotary outlet 16. Clean gas diffusion Rotary outlet 18, ash hopper 12 and overflow box 10. The housing 2 is square. The casing 2 is installed on the bracket 13 . The lower part of the housing 2 is equipped with an ash hopper 12 . The bottom of the ash hopper 12 is provided with a sewage outlet 11 . The upper part of the housing 2 is the clean air outlet 1 of the dust collector. Two flue gas passages 4 are horizontally and parallelly installed on the upper part of the housing 2 , and their two ends are fixed on the housing 2 . One end of the flue gas channel 4 is blocked by the casing 2, and the other end communicates with the flue gas inlet 3 equipped with a flange. The bottom of the flue gas passage 4 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com