Regeneration method and regeneration equipment for waste salt produced in flue gas desulfurization

A technology for regenerating equipment and flue gas, which is applied in the direction of separation methods, ammonium sulfate, chemical instruments and methods, etc., and can solve problems such as high operating costs, inability to treat waste salt from flue gas desulfurization, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

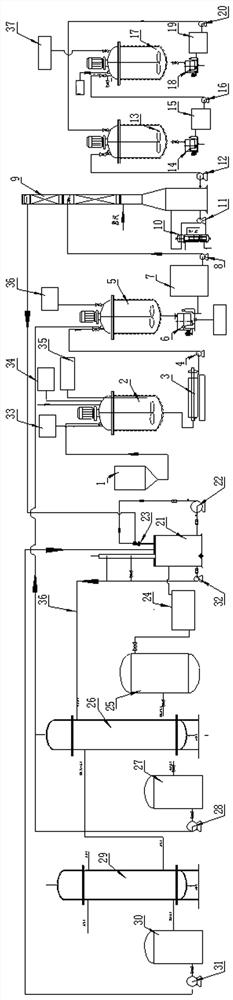

[0030] Such as figure 1 The flue gas desulfurization waste salt regeneration equipment shown includes a sodium bicarbonate generation device, an ammonium sulfate generation device, and an ammonium bicarbonate recovery device;

[0031] The sodium bicarbonate generation device comprises a desulfurization waste salt storage tank 1, a desulfurization waste salt pretreatment kettle 2, a plate and frame filter press 3, a sodium bicarbonate reaction kettle 5, and a sodium bicarbonate centrifuge 6 connected in sequence by pipelines , mother liquor storage tank I7; described ammonium sulfate generating device comprises ammonium bicarbonate decomposition tower 9, reboiler 10, sodium sulfate reaction still 13, sodium sulfate centrifuge 14, mother liquor storage tank II 15, sulfuric acid Ammonium reaction kettle 17, ammonium sulfate centrifuge 18, mother liquid storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com