Fiber cement product and production method thereof

A fiber cement and production method technology, applied in the field of fiber cement products, can solve problems such as increasing the cost of building materials, and achieve the effect of ensuring high-efficiency operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0067] Magnesium oxide powder is added to alkaline wastewater to make a desulfurizer, and sent to the desulfurization tower. The flue gas (with an oxygen content of 18vol%) enters the desulfurization tower from the flue gas inlet of the desulfurization tower, and after passing through three absorption spray layers, the sulfur dioxide gas is fully absorbed by the desulfurizer. After the desulfurizer absorbs sulfur dioxide, it forms an absorption product containing magnesium sulfate (at a temperature of 30°C and a density of 1.2t / m 3 ), is introduced into the slurry circulation tank in the lower part of the desulfurization tower by gravity. The slurry in the upper part of the slurry circulation tank in the tower is sent to the three absorption spray layers respectively, and the circulation volume of the three accounts for 50vt% of the total output. The pH of the slurry in the lower part of the slurry circulation tank in the tower reaches 6.5, and then it is discharged to the st...

Embodiment 1

[0073] The flue gas treatment slurry that Preparation Example 1 gained, the steel slag that collects from steel mill (specific surface area is 500m 2 / kg), fly ash from a coal-fired boiler, magnesium oxide, fibers and additives were mixed and stirred for 30 minutes to obtain a mixture. The mixture was made into a preform, maintained at a temperature of 30°C and a humidity of 60% for 10 hours, demolded and sanded to obtain a fiber cement product. See Table 3 for recipes. See Table 4 for performance test results.

[0074] Table 3. Formula of fiber cement products

[0075] Specification

Flue gas treatment slurry

magnesium oxide

additive

fiber

kg

60

15

15

10

1

10

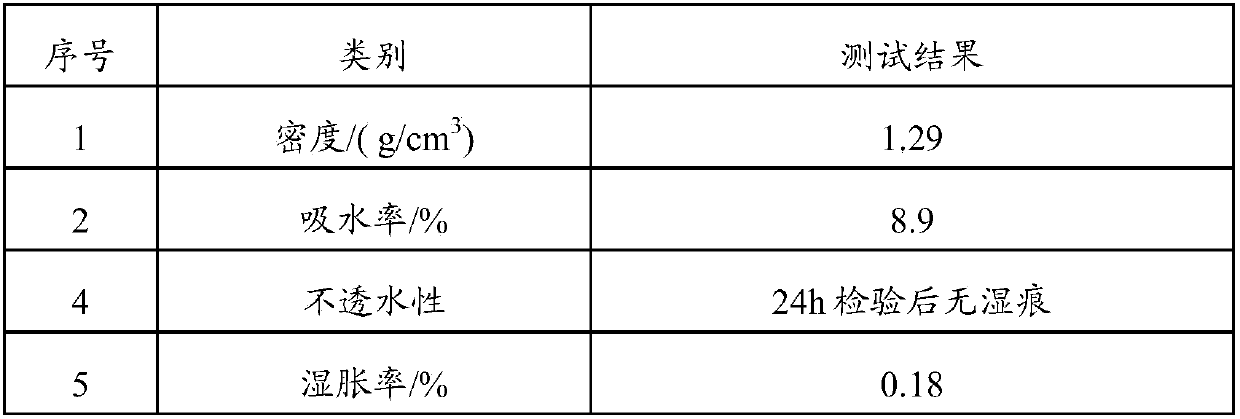

[0076] Table 4. Properties of fiber cement products

[0077]

[0078]

Embodiment 2

[0080] Except adopting the prescription of Table 5, all the other conditions are identical with embodiment 1. See Table 6 for performance test results.

[0081] Table 5. Formula of fiber cement products

[0082] Specification

Flue gas treatment slurry

magnesium oxide

additive

fiber

kg

65

15

20

10

1

5

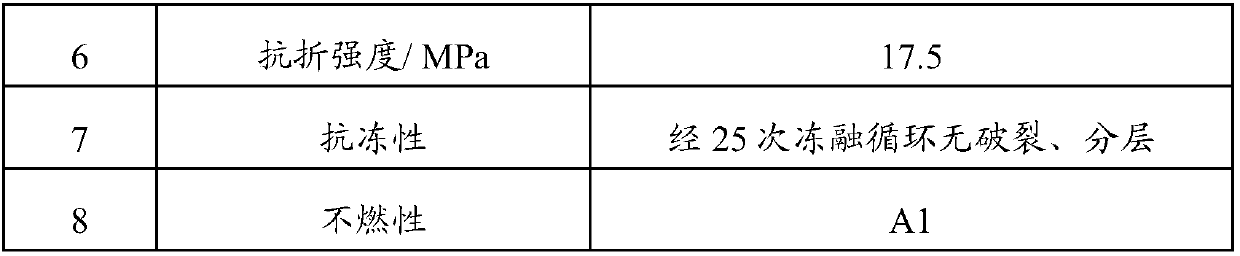

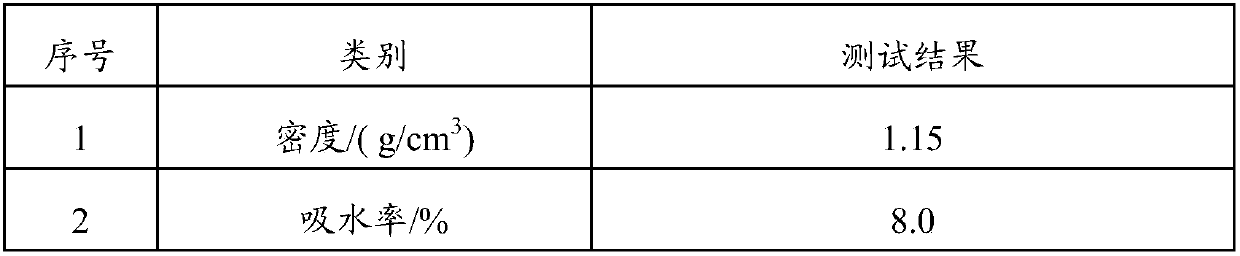

[0083] Table 6. Properties of fiber cement products

[0084] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com