Method for preparing fiber cement products based on flue gas desulfurization and denitrification of red mud

A technology for desulfurization, denitrification, and fiber manufacturing, which is applied in the field of fiber cement products. It can solve the problems of low waste utilization rate, difficult industrial production, and complex components, and achieve the effects of ensuring high-efficiency operation, low price, and overcoming high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] According to the formula in Table 1, mix the components uniformly to obtain a flue gas treatment agent, then add alkaline wastewater to make a flue gas desulfurization and denitrification agent slurry, and send it to the desulfurization tower. The flue gas (oxygen content is 18vol%) enters the desulfurization tower from the flue gas inlet of the desulfurization tower, and undergoes three layers of ozone oxidation (ozone comes from the ozone generator, and the ozone concentration of the ozone generator is 10wt%) and flue gas desulfurization and denitrification agent slurry After absorbing the spray layer, sulfur dioxide and nitrogen oxides are fully absorbed by the flue gas desulfurization and denitrification agent slurry. After the flue gas desulfurization and denitrification agent slurry absorbs sulfur dioxide and nitrogen oxides, it is introduced into the slurry circulation tank in the lower part of the desulfurization tower through the action of gravity. The slurry i...

Embodiment 2

[0071] Using the flue gas treatment agent formula in Table 6, the working conditions of flue gas desulfurization and denitrification are shown in Table 7 and Table 8 below. All the other conditions are the same as in Example 1. See Table 9 for the recipe. See Table 10 for performance test results.

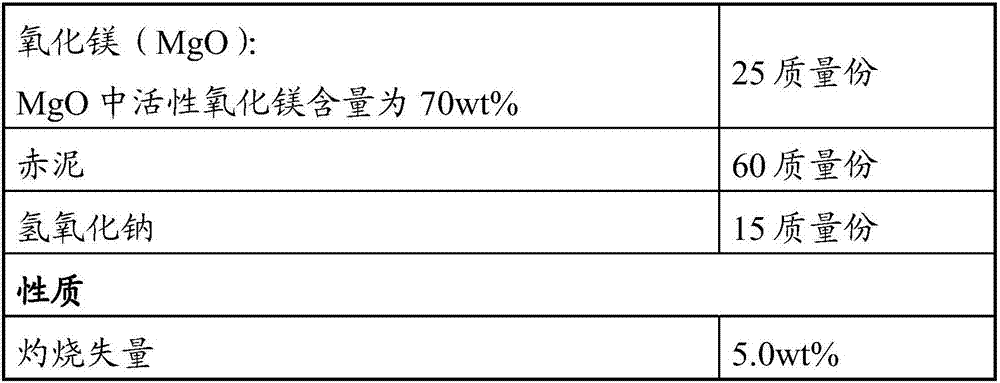

[0072] Table 6 Flue gas treatment agent formula

[0073]

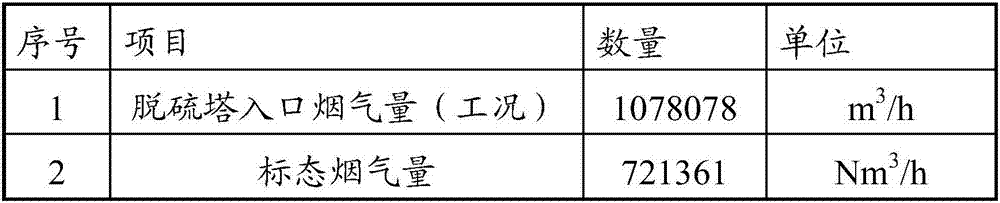

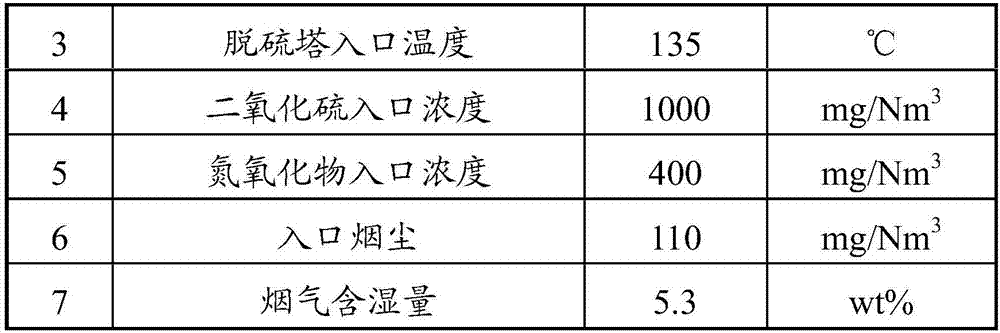

[0074] Table 7 Desulfurization and denitrification working condition parameters

[0075] serial number

project

quantity

unit

1

Flue gas volume at the inlet of desulfurization tower (working condition)

1037075

m 3 / h

2

Standard smoke volume

701364

N m 3 / h

3

Desulfurization tower inlet temperature

140

℃

4

SO2 inlet concentration

980

mg / Nm 3

5

NOx inlet concentration

410

mg / Nm 3

6

Inlet soot

100

mg / Nm 3

7

5.3

wt%

[0076] Table 8 Emissions fro...

Embodiment 3

[0083] The formulation of the flue gas treatment agent in Table 11 and the working conditions of flue gas desulfurization and denitrification are shown in Table 12 and Table 13 below. All the other conditions are the same as in Example 1. See Table 14 for the recipe. See Table 15 for performance test results.

[0084] Table 11 Flue gas treatment agent formula

[0085]

[0086] Table 12 Desulfurization and denitrification working condition parameters

[0087] serial number

project

quantity

unit

1

Flue gas volume at the inlet of desulfurization tower (working condition)

1092076

m 3 / h

2

Standard smoke volume

741361

N m 3 / h

3

Desulfurization tower inlet temperature

143

℃

4

SO2 inlet concentration

960

mg / Nm 3

5

NOx inlet concentration

392

mg / Nm 3

6

Inlet soot

113

mg / Nm 3

7

5.8

wt%

[0088] Table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com