Magnesium sulfate production device and method by flue gas desulfurization

A magnesium sulfate and flue gas technology, applied in the direction of magnesium sulfate, etc., can solve the problems of high production cost per ton of ore, high desulfurization operation cost, and high steam consumption of magnesium sulfate, so as to reduce operating costs, ensure desulfurization efficiency and by-product quality, Effect of reducing steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

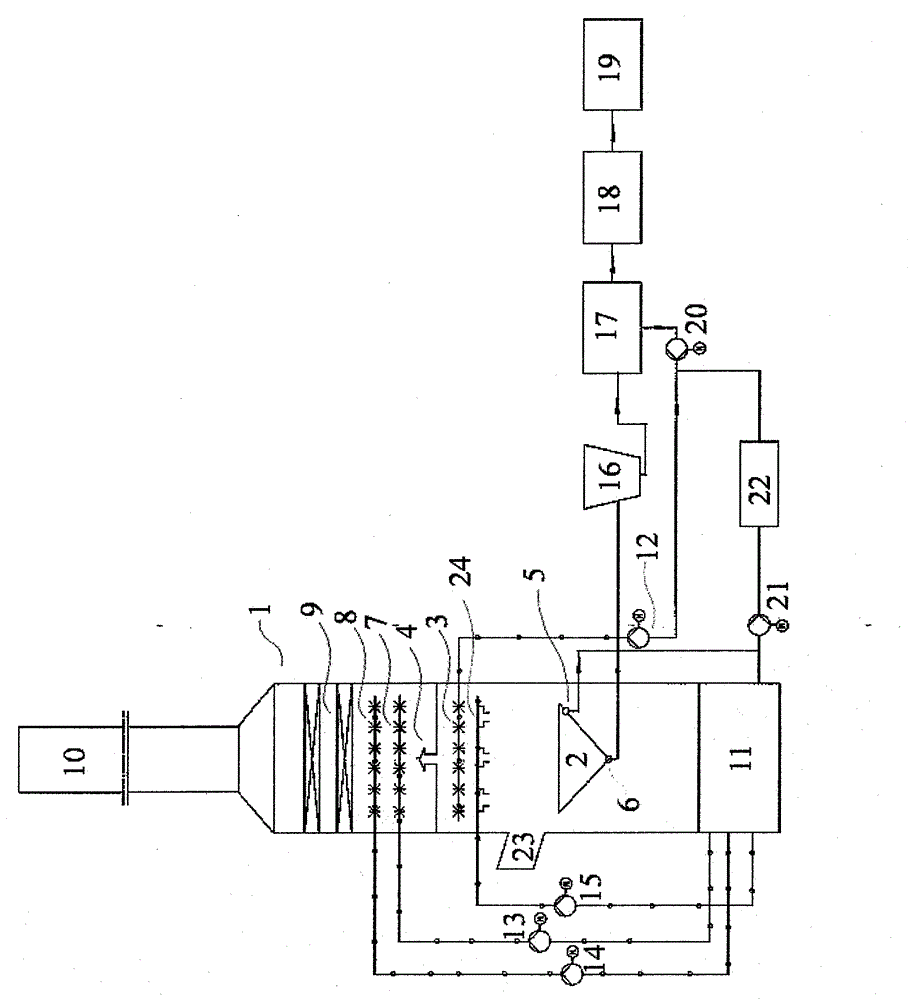

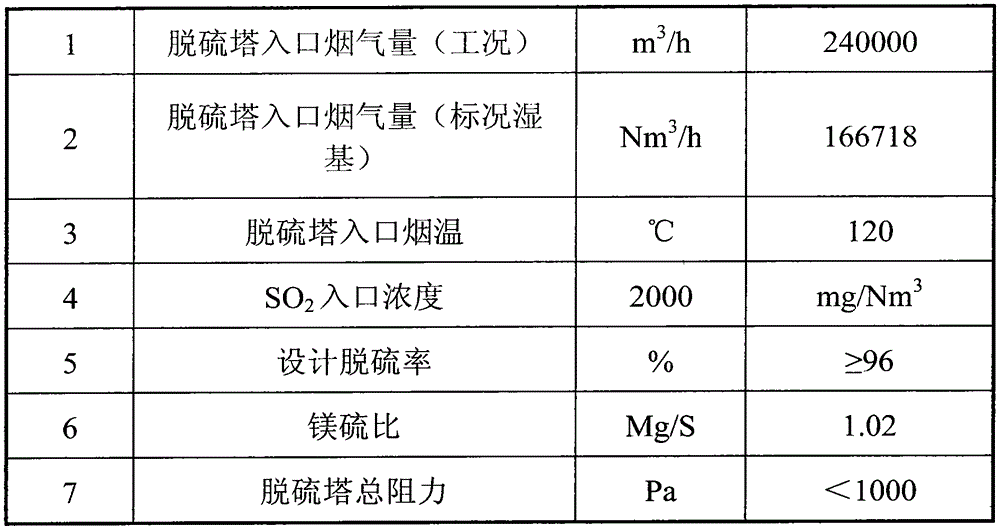

[0068] figure 1 It is a schematic diagram of the device of the present embodiment 1, and the device includes a desulfurization tower 1. The middle and lower part of the desulfurization tower 1 is provided with a flue gas inlet 23 and the top is provided with a flue gas outlet 10 . An over-temperature emergency cooling device 24 is arranged above the flue gas inlet 23 to solve the occurrence of flue gas temperature over-temperature after the bypass flue is cancelled. When the temperature exceeds the limit temperature 180, the slurry in the upper part of the slurry circulation tank 11 is sent to the accident area determined by the over-temperature emergency cooling device 24 through the circulation pump 15 of the over-temperature emergency cooling device 24 for emergency cooling of the desulfurization tower 1. An evaporative concentration spray layer 3 is arranged above the overtemperature emergency cooling device 24, and a liquid accumulator 4 is arranged above the evaporative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com