Desulphurizing tower for desulphurizing with seawater soda-residue emulsion

A desulfurization tower and seawater technology, applied in the field of desulfurization towers, can solve the problems of being unsuitable for desulfurization of seawater white mud emulsion, there is no integrated production device, and there are many desulfurization devices. Small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

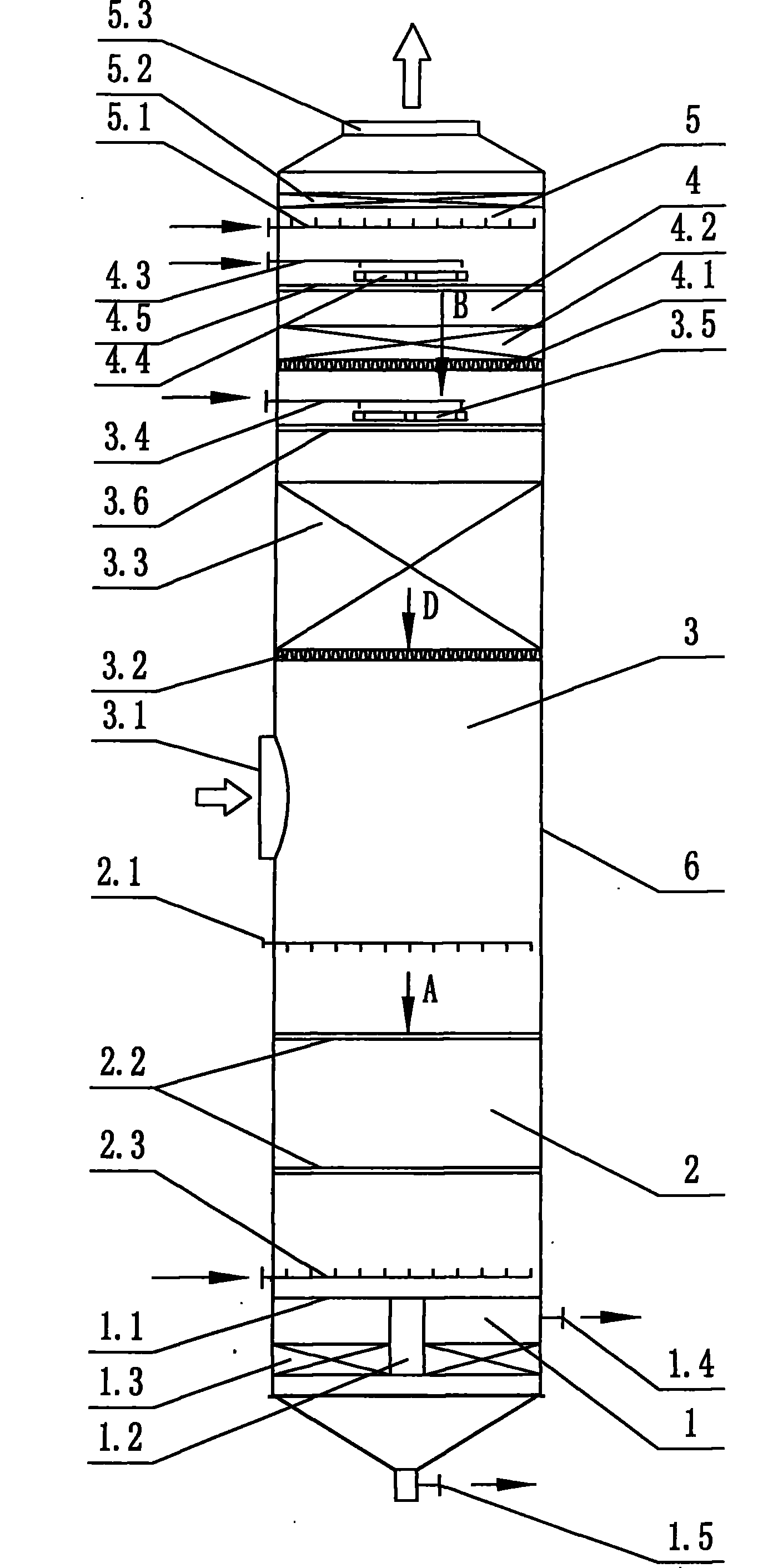

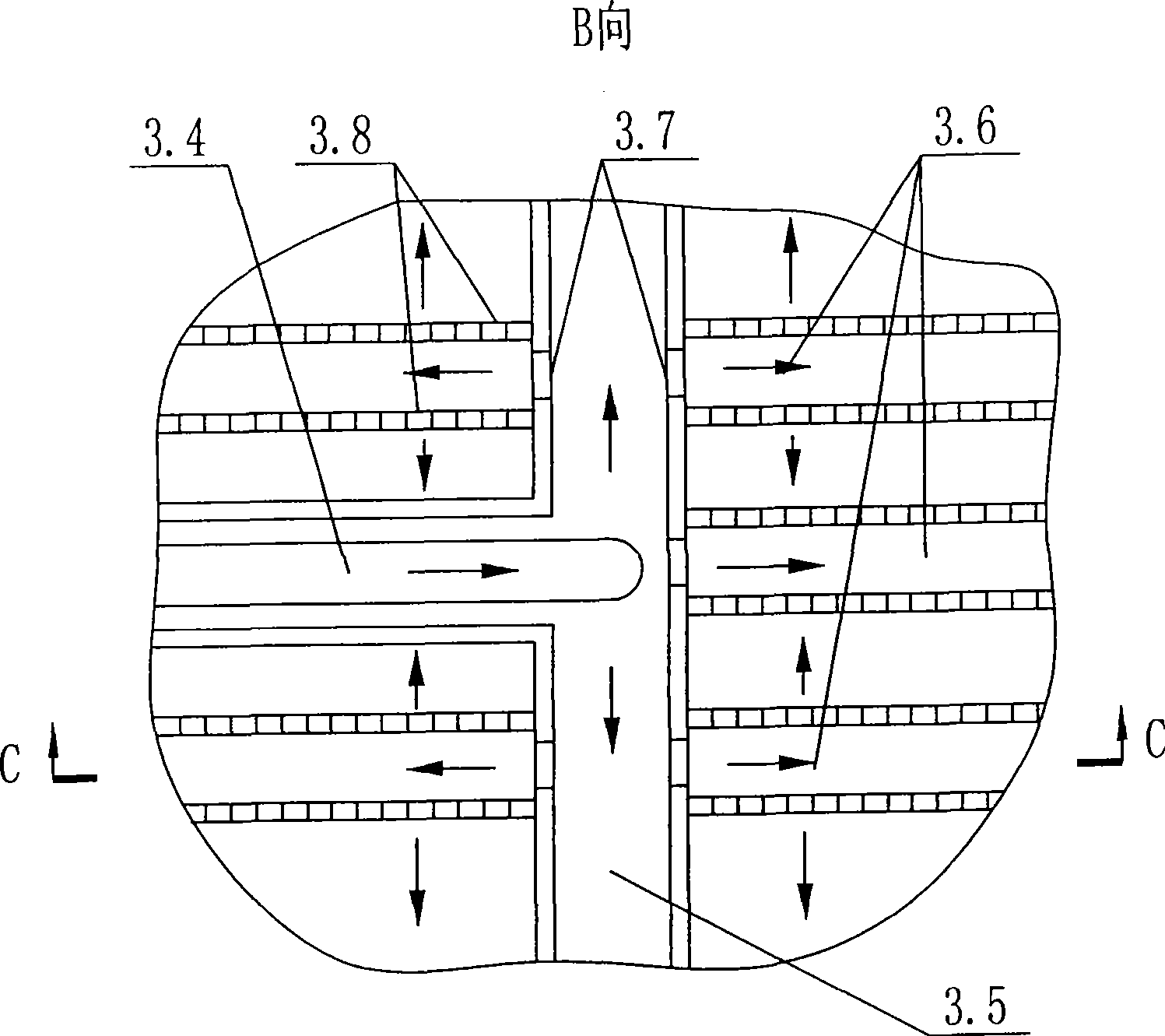

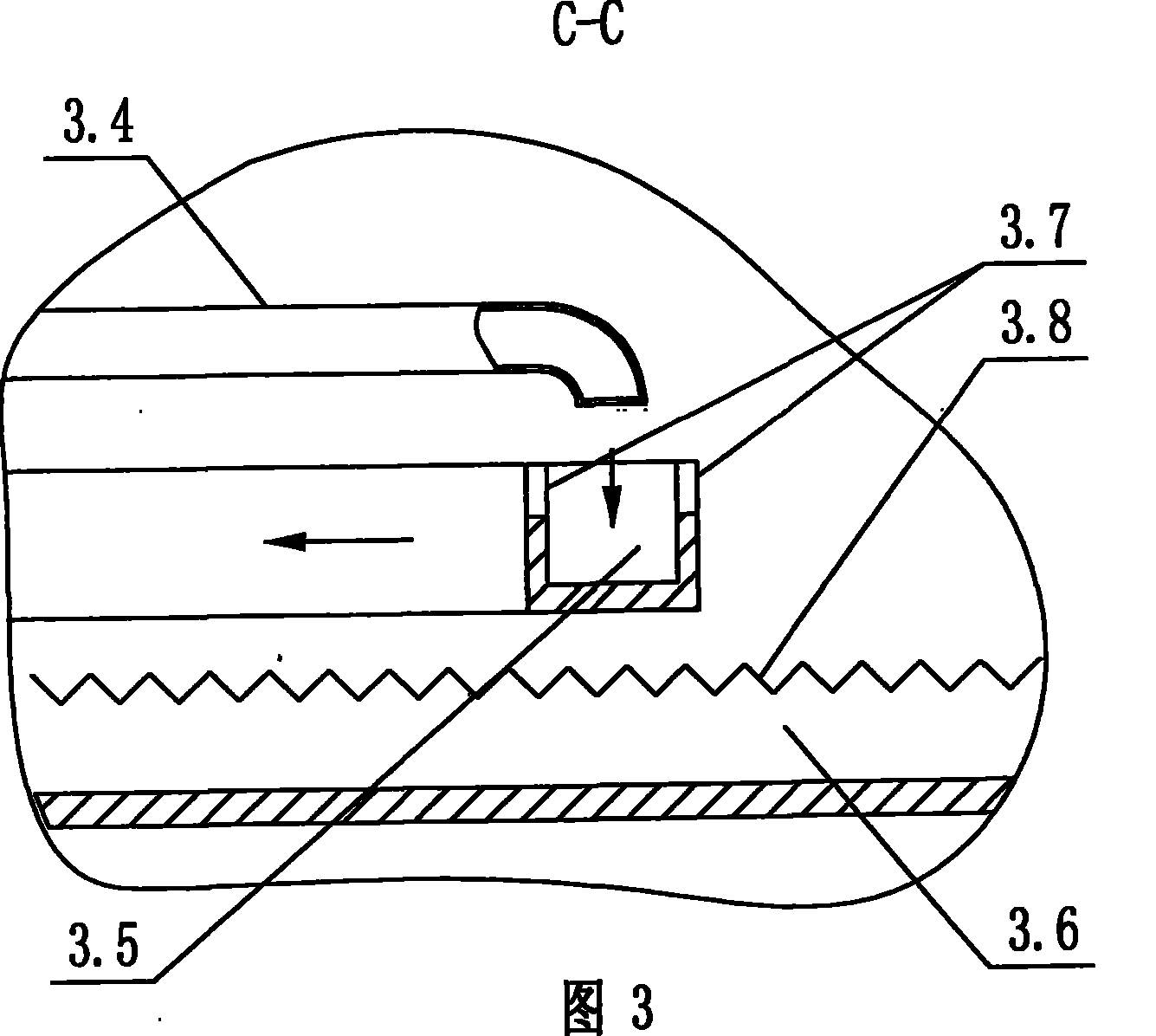

[0018] figure 1 It is shown that there are five functional sections in the tower body 6 from top to bottom: defogging section 5, seawater absorption section 4, seawater white mud milk absorption section 3, oxidation section 2 and clarification section 1. The demister 5.2 in the defogging section 5 can be a wire mesh corrugated packing, or a corrugated plate mist eliminator, and this embodiment uses a wire mesh corrugated packing. There is a cleaning pipe 5.1 below the mist eliminator 5.2, and the cleaning pipe 5.1 has a plurality of branch pipes on both sides of the tower, and a plurality of nozzles are arranged above the pipe, which can clean the entire mist eliminator 5.2. Seawater white mud milk absorption section 3 is the main functional section of the tower, and water distribution tank 3.5 is a general overflow tank type liquid distribution device, such as "King" type, "H" type and other strip water tanks. This embodiment adopts Wang "character" type strip water tank, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com