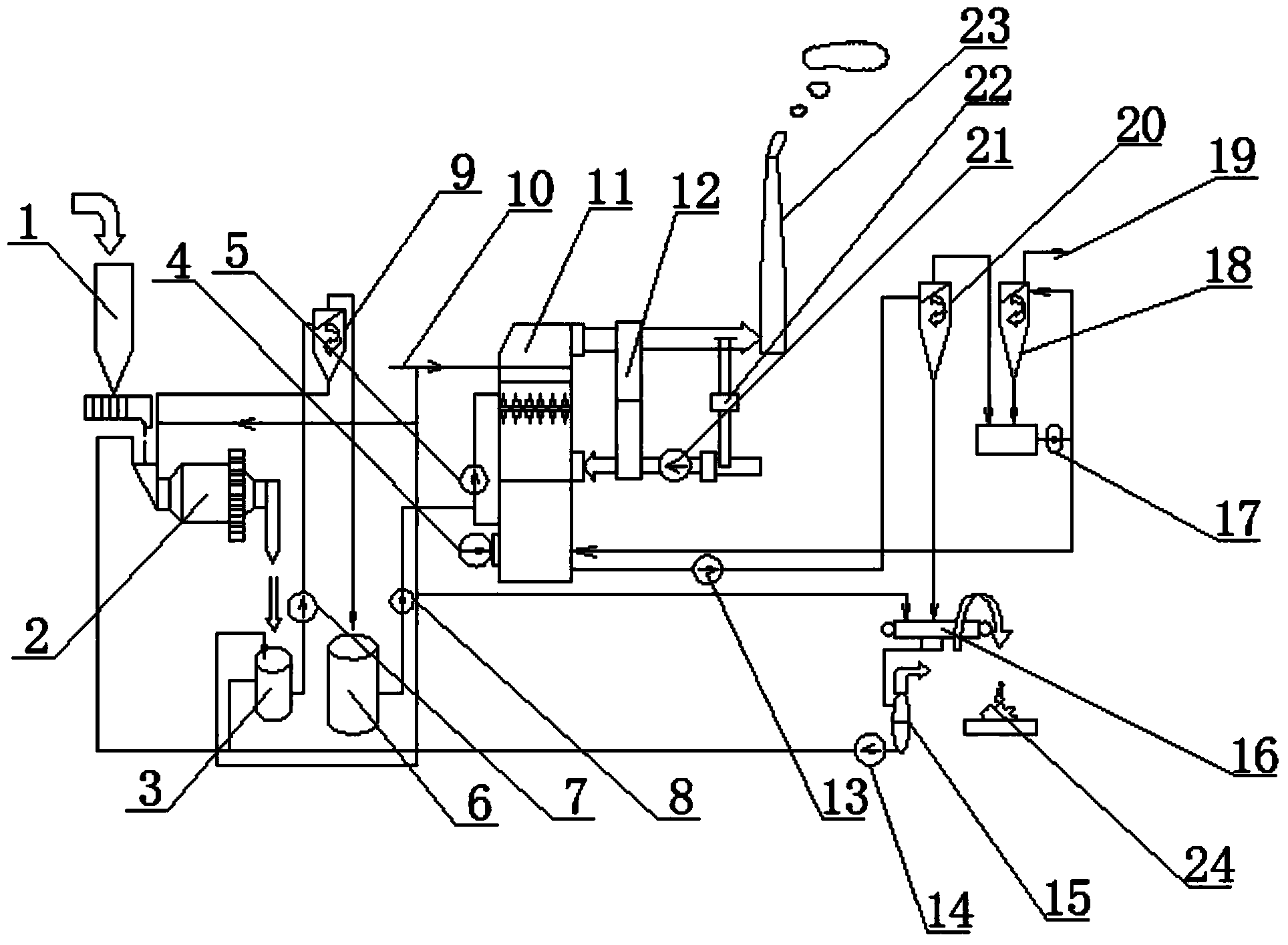

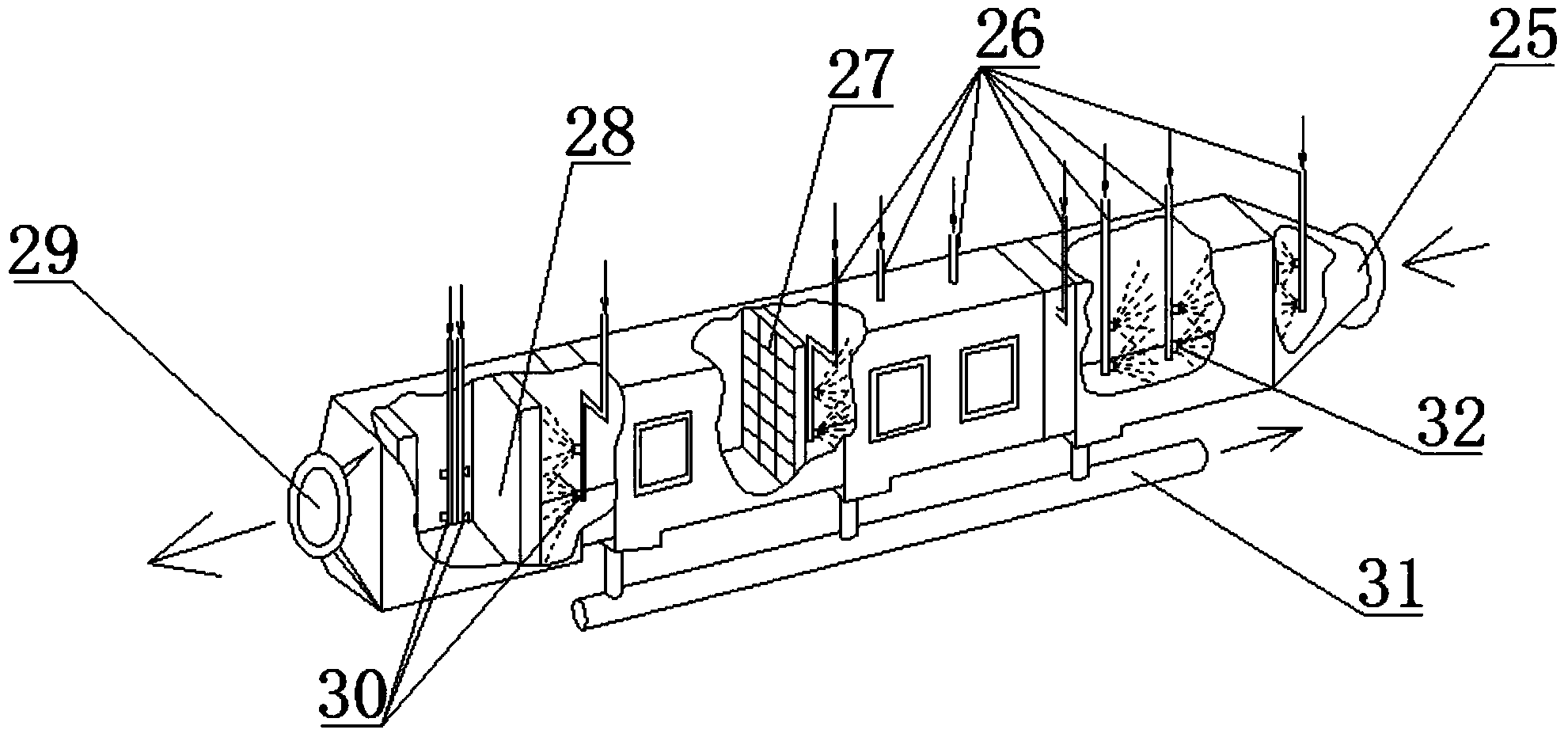

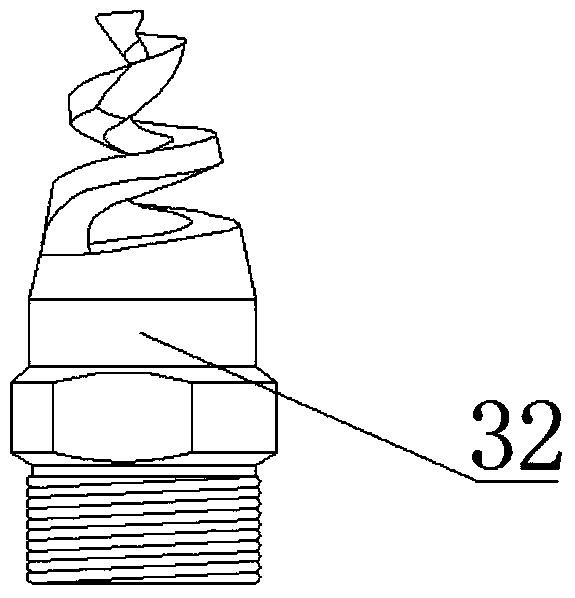

Horizontal spraying and desulfurizing device and method for aluminum electrolysis fume

A technology of spray desulfurization and aluminum electrolysis, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, can solve problems such as corrosion, low desulfurization efficiency, and high operation and maintenance costs, so as to improve safety performance, reduce investment costs, and reduce The effect of desulfurization operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment one: SO Three kinds of states formed after being dissolved in water (SO 3 2- 、HSO 3- and H 2 SO 3 ) and pH

[0034] SO 2 After being dissolved in water, a series of dissociation equilibriums will be produced:

[0035]

[0036]

[0037]

[0038]

[0039] From formula (3):

[0040] [H 2 SO 3 ]=[H + ]·[HSO 3 - ] / Ka 1 (5)

[0041] From formula (4):

[0042] [SO 3 2- ] = Ka 2 ·[HSO 3 - -] / [H + ] (6)

[0043] While the total concentration in the liquid phase [SO 2 ] is always:

[0044] [SO 2 ] Total=[SO 3 2- ]+[HSO 3 - ]+[H 2 SO 3 ] (7)

[0045] Substitute (5) and (6) into (7) to get:

[0046] [HSO 3 - ] / [SO 2 ] Total=Ka 1 [H + ] / ([H + ] 2+ Ka 2 ·Ka1+Ka 1 [H + ]) (8)

[0047] And by formula (5), formula (6) and formula (8):

[0048] [H 2 SO 3 ] / [SO 2 ] Total=[H + ] 2 / ([H + ] 2 +Ka 2 · Ka 1 +Ka 1 [H + ]) (9)

[0049] [SO 3 2- ] / [SO 2 ] Total=Ka 2 · Ka 1 / ([H + ] 2 +Ka 2 · Ka 1 +Ka...

Embodiment 2

[0051] Example 2: Reaction mechanism of lime wet desulfurization at different pH values

[0052] (a)pH>9

[0053] The sulfur anion in the liquid phase is mainly SO2-3, which interacts with Ca 2+ Combined as CaSO 3 1 / 2H 2 O:

[0054]

[0055] In addition, because the flue gas contains oxygen, a small amount of CaSO 3 oxidized to CaSO 4 2H 2 O. At the same time CO in the flue gas at high pH 2 Soluble in water, and with Ca 2+ bound as CaCO 3 :

[0056]

[0057] When the pH of milk of lime>12, the direct desulfurization process of milk of lime will generate CaSO according to the above reaction 3 1 / 2H 2 O, CaCO 3 and CaSO 4 2H 2 O, the solubility of these calcium salts is extremely low, and it is easy to reach supersaturated crystallization, which is the main reason for the easy scaling of lime wet desulfurization when pH>9. The crystallization forms a scale layer on the wall of the desulfurization tower and the internal parts of the tower, and in severe cases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com