Metal-smelting desulfurizing and dedusting technology for environmentally friendly deduster

A technology for metal smelting, desulfurization and dust removal, which is applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve the problems of recovery and utilization of products that cannot be desulfurized, reduce process configuration, and low economic benefits, so as to achieve good economic benefits and simplify Technological process, the effect of considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

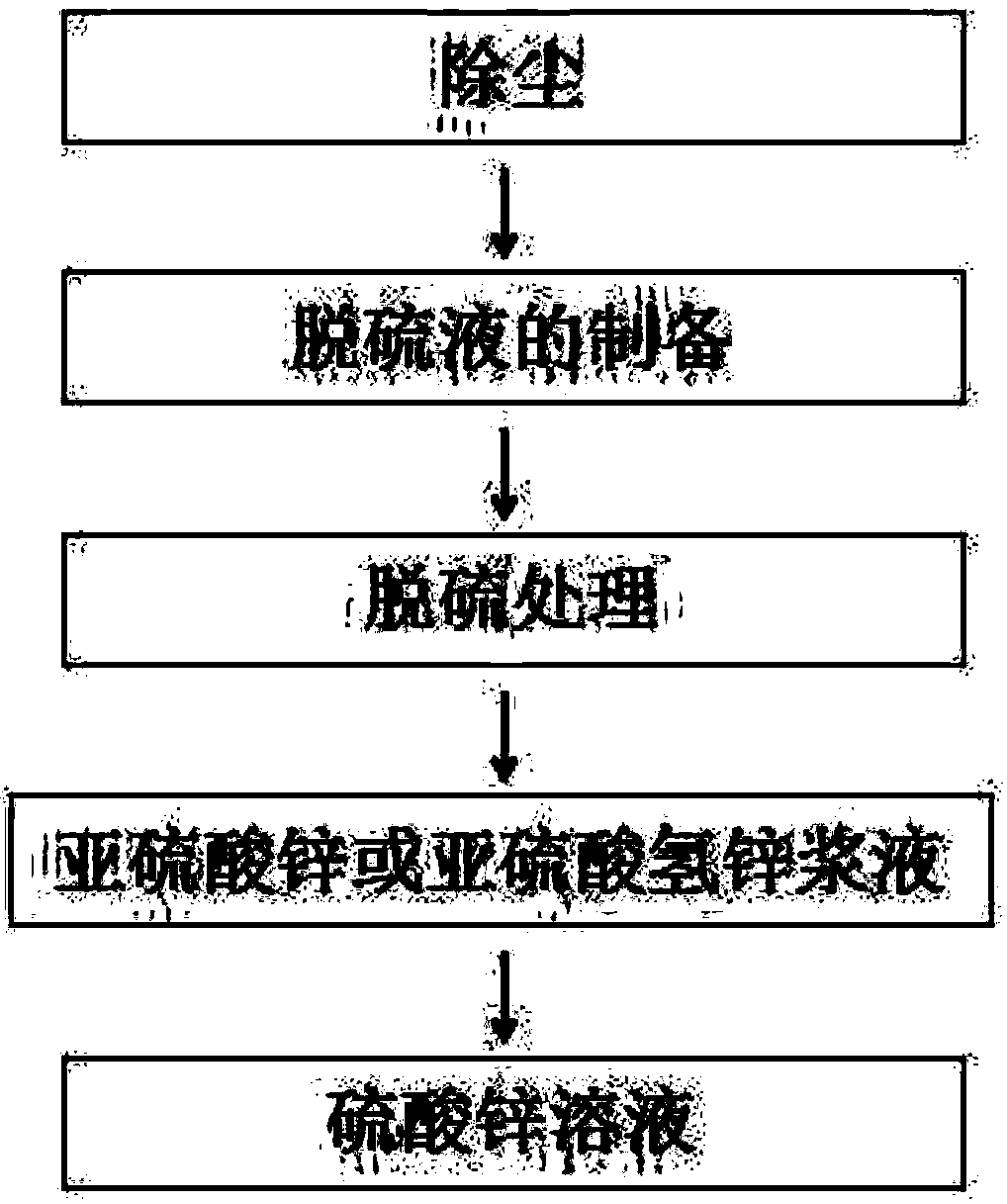

Image

Examples

Embodiment 1

[0024] A metal smelting desulfurization and dedusting process for an environmental protection dust collector, comprising the following steps:

[0025] (1) Dust removal: introduce the flue gas produced in the smelting production process into the cyclone dust collector for dust removal treatment;

[0026] (2) Preparation of desulfurization liquid;

[0027] (3) Desulfurization treatment: The flue gas after dust removal by the cyclone dust collector is pressurized by the booster fan and then sent to the desulfurization tower, and the desulfurization liquid in the circulation pool is supplied to the nozzle in the desulfurization tower through the circulation pump, and is sprayed by the atomization nozzle. The flue gas is sprayed, the desulfurization liquid is in countercurrent contact with the smelting flue gas, and the zinc sulfite or zinc bisulfite slurry reacted with the smelting flue gas falls into the circulating pool;

Embodiment 2

[0036] A metal smelting desulfurization and dedusting process for an environmental protection dust collector, comprising the following steps:

[0037] (1) Dust removal: introduce the flue gas produced in the smelting production process into the cyclone dust collector for dust removal treatment;

[0038] (2) Preparation of desulfurization liquid;

[0039] (3) Desulfurization treatment: The flue gas after dust removal by the cyclone dust collector is pressurized by the booster fan and then sent to the desulfurization tower, and the desulfurization liquid in the circulation pool is supplied to the nozzle in the desulfurization tower through the circulation pump, and is sprayed by the atomization nozzle. The flue gas is sprayed, the desulfurization liquid is in countercurrent contact with the smelting flue gas, and the zinc sulfite or zinc bisulfite slurry reacted with the smelting flue gas falls into the circulating pool;

[0040] (4) Zinc sulfite or zinc bisulfite slurry: Use a...

Embodiment 3

[0048] A metal smelting desulfurization and dedusting process for an environmental protection dust collector, comprising the following steps:

[0049] (1) Dust removal: introduce the flue gas produced in the smelting production process into the cyclone dust collector for dust removal treatment;

[0050] (2) Preparation of desulfurization liquid;

[0051] (3) Desulfurization treatment: The flue gas after dust removal by the cyclone dust collector is pressurized by the booster fan and then sent to the desulfurization tower, and the desulfurization liquid in the circulation pool is supplied to the nozzle in the desulfurization tower through the circulation pump, and is sprayed by the atomization nozzle. The flue gas is sprayed, the desulfurization liquid is in countercurrent contact with the smelting flue gas, and the zinc sulfite or zinc bisulfite slurry reacted with the smelting flue gas falls into the circulating pool;

[0052](4) Zinc sulfite or zinc bisulfite slurry: Use a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com