Desulfurization, denitration, dust removal and white smoke removal integrated intelligent system and desulfurization, dust removal and white smoke removal method thereof

A technology of desulfurization and dust removal, intelligent system, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of large consumption of raw materials, complicated operation, and inability to achieve dewhitening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the following, the present invention will be described in more detail through specific embodiments, so as to facilitate the understanding of the technical solution of the present invention, but it is not used to limit the protection scope of the present invention.

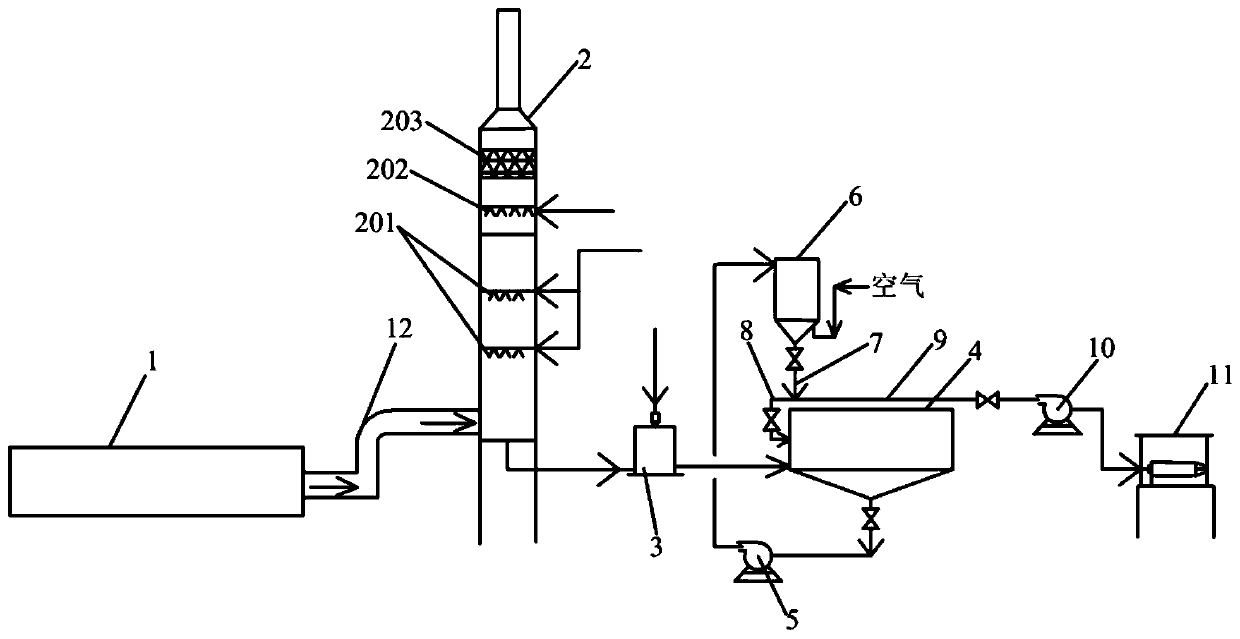

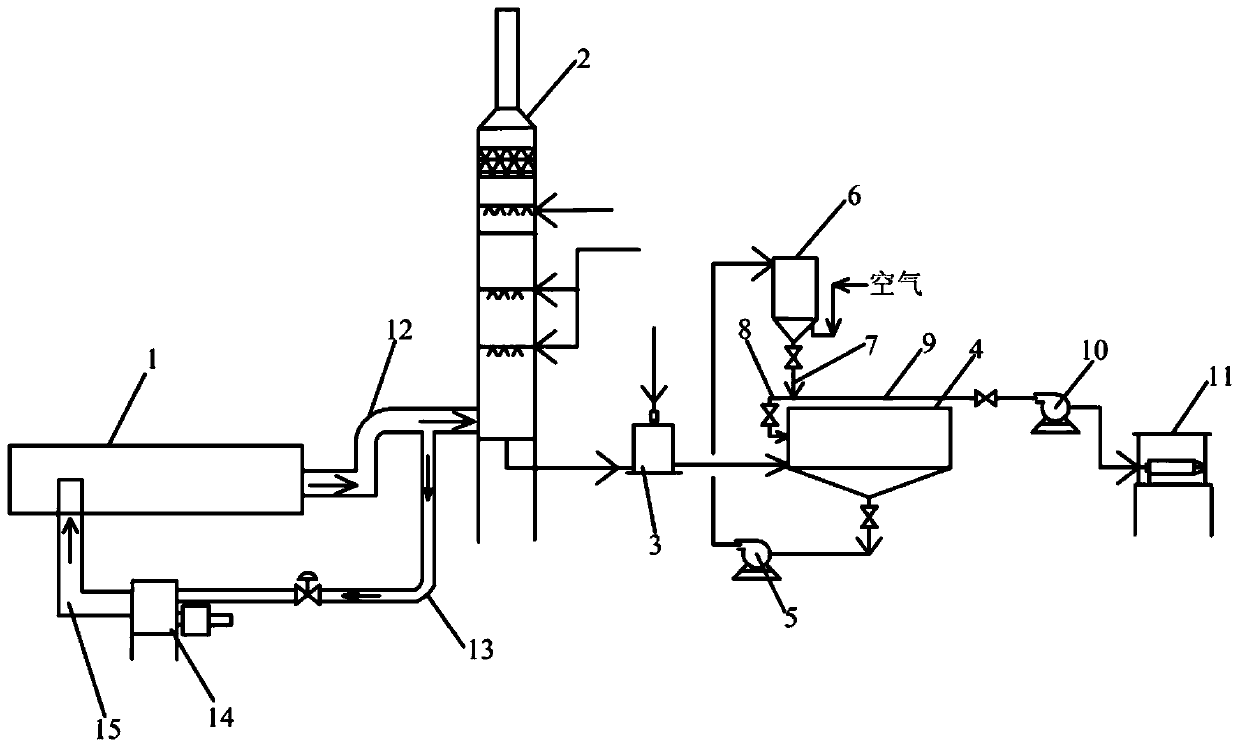

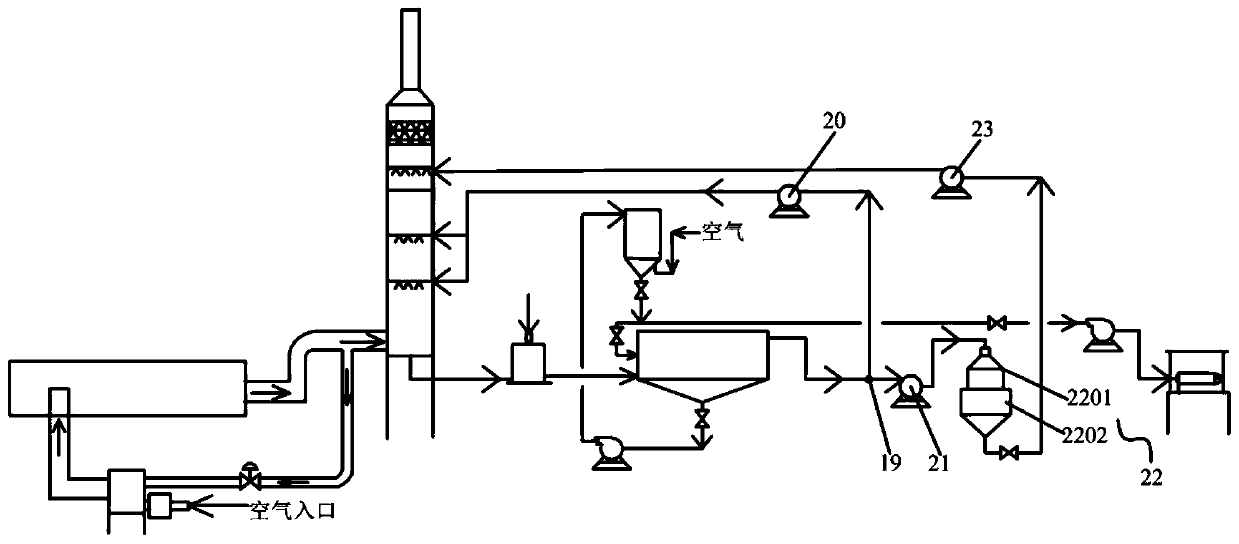

[0040] The invention provides an integrated intelligent system for desulfurization, dust removal and whitening, such as figure 1 As shown, the system includes a tail gas generation system, a desulfurization, dust removal and whitening system connected to the tail gas generation system through the first gas pipeline, a reactor connected to the desulfurization, dust removal and whitening system, and a sedimentation tank connected to the reactor; The bottom of the tank is connected with the oxidation tank through the first slurry pump and pipeline. The oxidation tank is connected with the sedimentation tank through the material pipeline supervisor and the first branch pipe. The oxidation tank is also connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com