Absorption tower desulphurization duster device

A desulfurization dust collector and absorption tower technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as affecting the output value of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

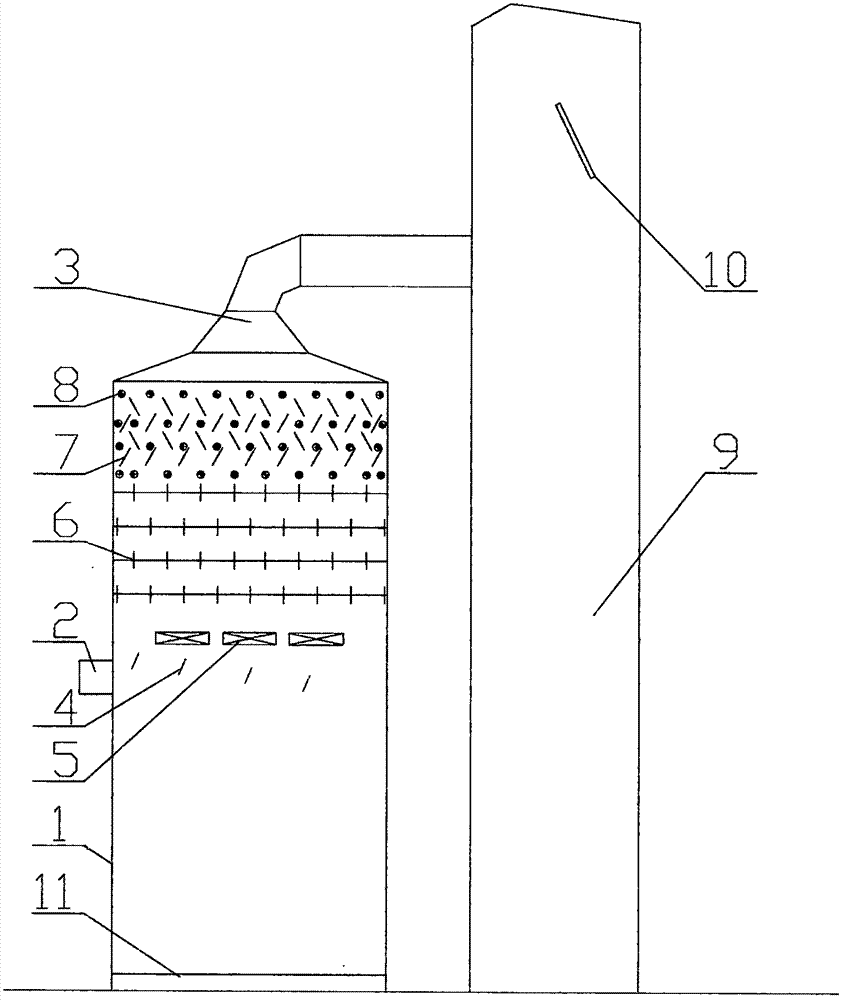

[0014] A kind of absorption tower desulfurization deduster device of the present invention is described further below in conjunction with accompanying drawing, as shown in accompanying drawing, it is made up of tower body (1), air inlet (2), air outlet (3) etc. Outline, tower The inside is composed of a guide plate (4), a guide impeller (5), a lime slurry spray layer (6), a plate type dust collector (7), a water pipe and a nozzle (8). ) into the fixed guide plate (4) to divert the gas, and the guide impeller (5) rotates to mix, so that the mixed gas of smoke and dust in the tower is evenly distributed, and the sulfur dioxide and lime slurry in the mixed gas of smoke and dust are fully allowed to spray the layer (6) A chemical reaction desulfurization occurs, and then the smoke and dust mixed gas enters the plate type dust collector (7) for dust removal. The smoke and dust mixed gas and the plate are fully rubbed and the dust is adsorbed on the plate. Under the action of water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com