System device and method for recycling sulfur dioxide from fume to prepare sulfur

A sulfur dioxide and system device technology, which is applied in the direction of sulfur preparation/purification, energy input, etc., can solve the problems of high sulfur dioxide content and incomplete sulfur recovery, and achieve low sulfur content in flue gas, reduced emissions, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

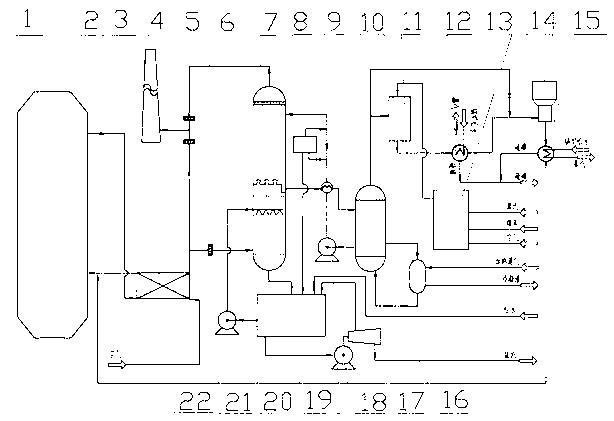

[0114] Taking the high-efficiency boiler of a large power plant as an example, a million-kilowatt generator set consumes 400t / h of thermal coal of 5500kcal / kg, and the flue gas volume is 3.2 million Nm3 / h. Based on the coal-fired sulfur content of 1.5%, and 80% of the flue gas entering the flue gas, the sulfur dioxide content of the flue gas is 9600kg / h, and the concentration is 3000mg / Nm3.

[0115] The device of the present invention reclaims sulfur dioxide from flue gas to produce the process and material data of sulfur as follows:

[0116] The high-temperature flue gas from the boiler 1 and the air entering the boiler 1 exchange heat in the air preheater 2 and cool down to 150°C, after being washed and cooled by the cooling tower 7, it enters the bottom of the absorption tower 8 at 60-65°C, and the flue gas When it flows upwards in the tower, it is fully contacted with the circulating absorption liquid for absorption. The sulfur dioxide in the flue gas reacts with the sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com