Patents

Literature

65results about "Magnesium sulfites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

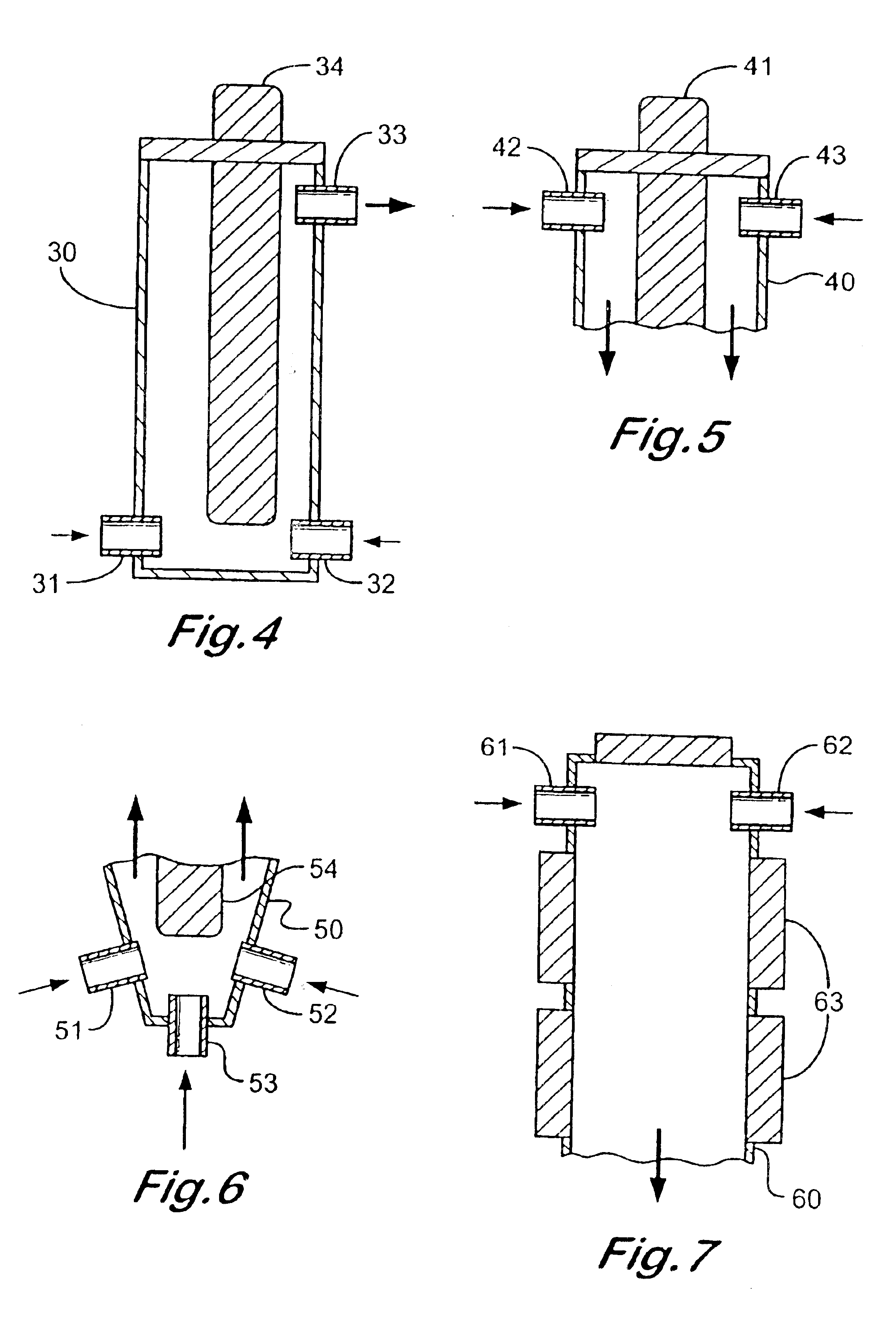

Multiple stream high pressure mixer/reactor

InactiveUS6221332B1Improve reliabilityFew and less partCalcium/strontium/barium carbonatesPressurized chemical processStream flowLow density

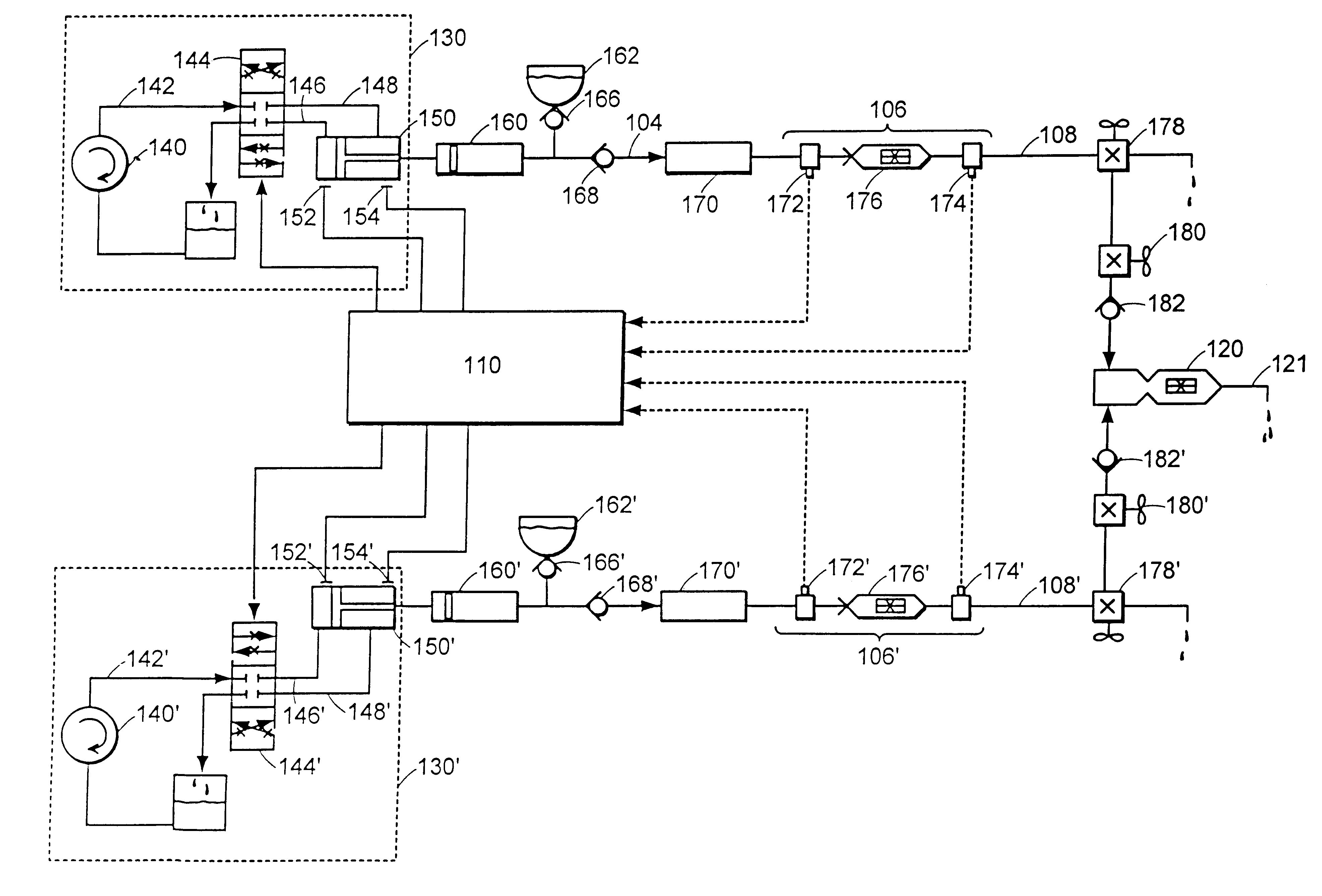

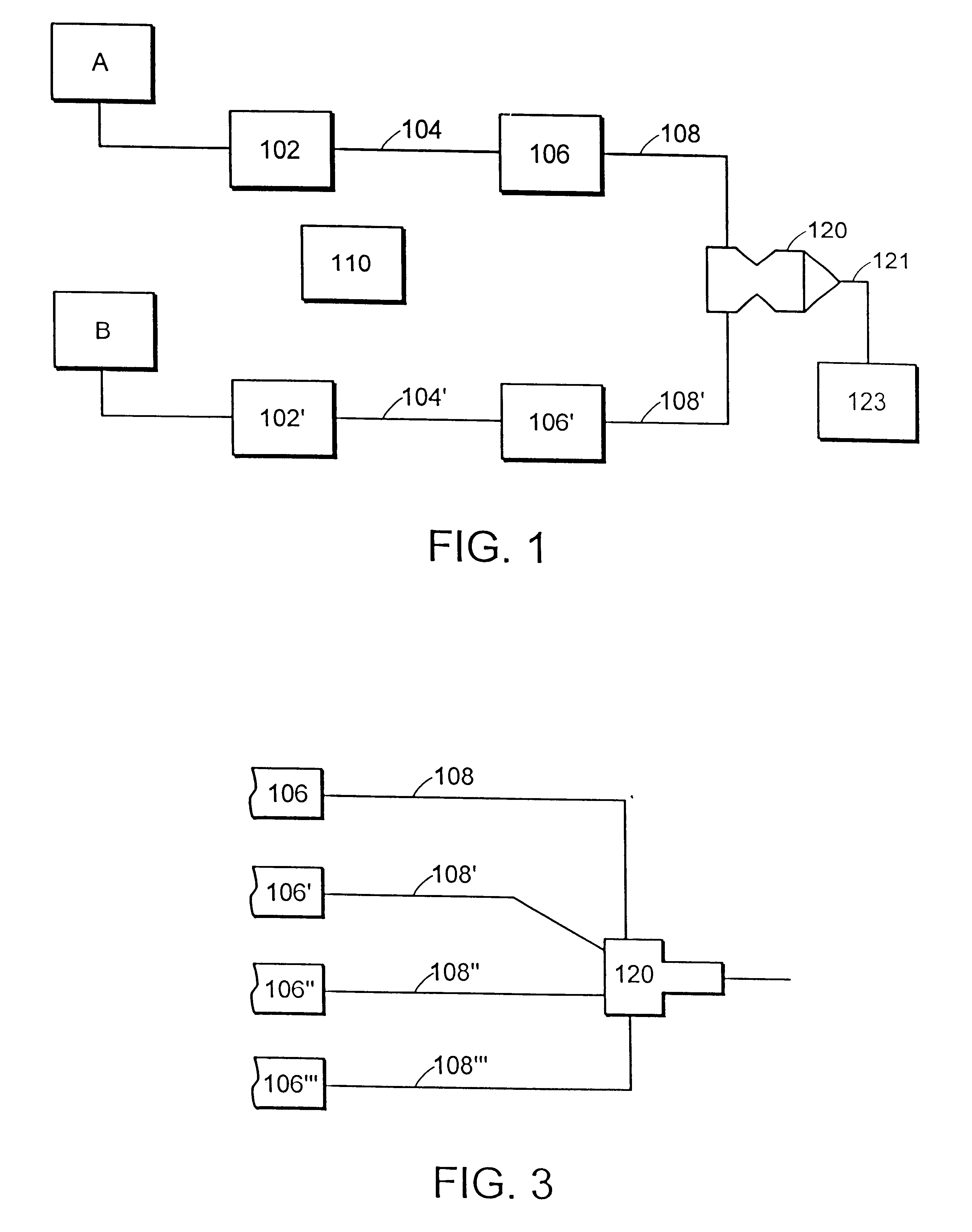

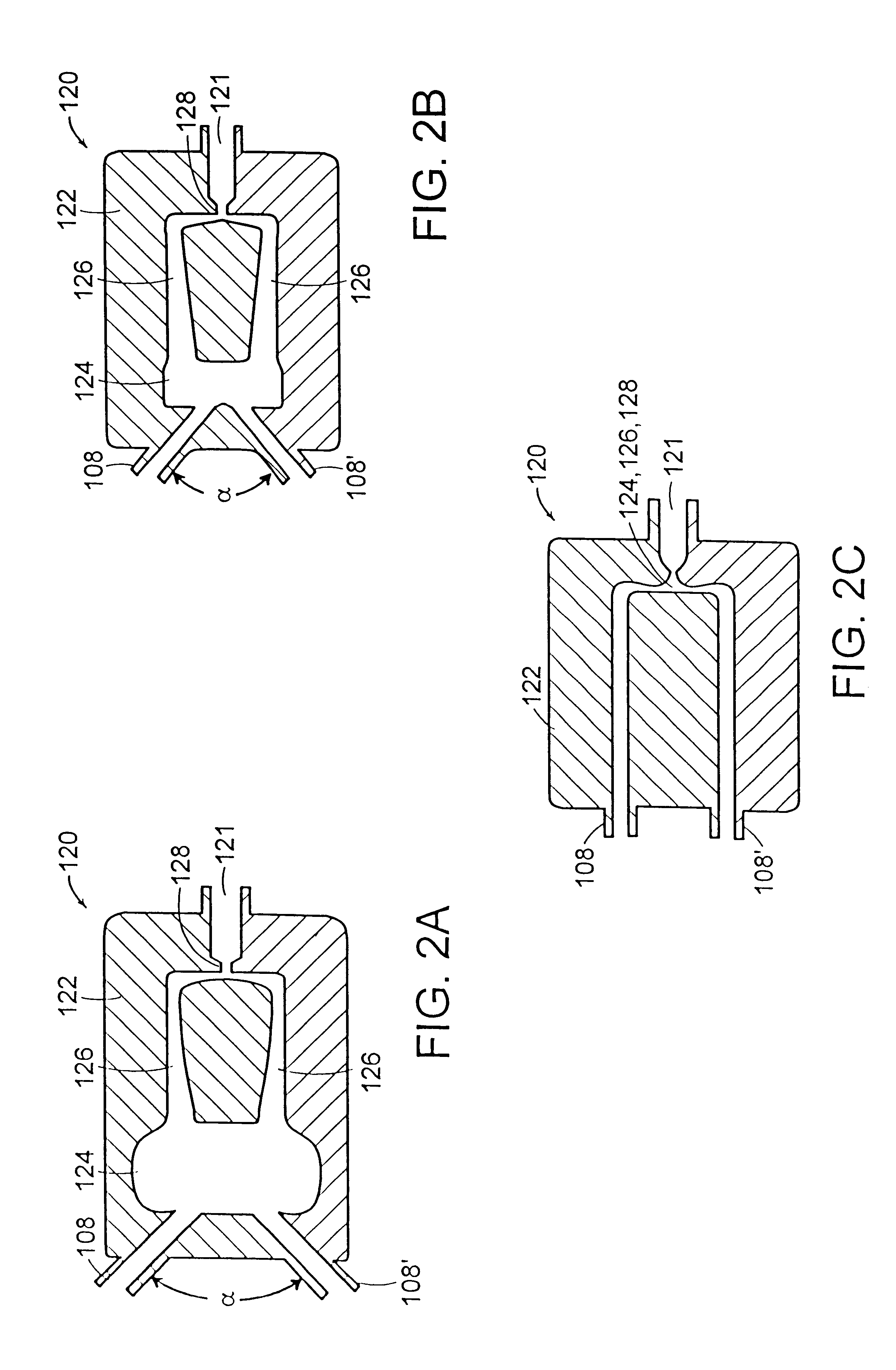

Enhanced macromixing, mesomixing, and micromixing of multiple discrete reactant streams, particularly for precipitation reactions of low density pumpable fluids, are obtained by controlled continuous high pressure multiple reactant streams flowing into a chemical mixer / reactor. Individual reactant streams are pressurized to about 8,000 to 50,000 psi and achieve velocities up to about 250 meters / second in the final stage of the chemical mixer / reactor. Reactant flows are controlled by a combination of a fixed restriction and a variable driving pump.

Owner:MICROFLUIDICS INT

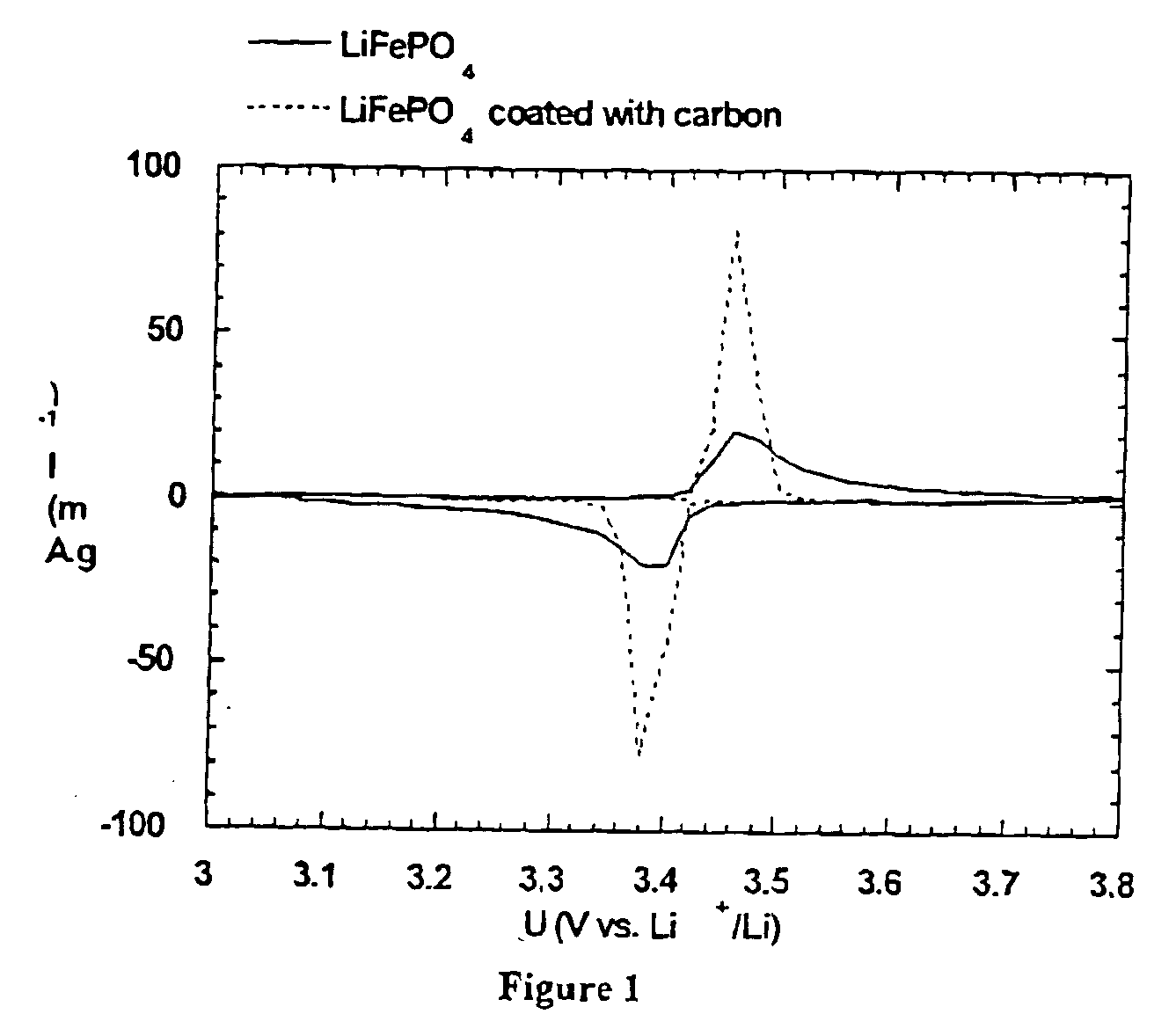

Synthesis method for carbon material based on lixm1-ym'(xo4)n

InactiveUS20040086445A1Improve performanceLow costHybrid capacitorsElectrolytic capacitorsElectrical conductorSynthesis methods

Method of synthesis for a material made of particles having a core and a coating and / or being connected to each other by carbon cross-linking, the core of these particles containing at least one compound of formula LixM1-yM'y(XO4)n, in which x,y and n are numbers such as 0<=x<=2, 0<=y<=0.6 and 1<=n<=1.5, M is a transition metal, M' is an element with fixed valency, and the synthesis is carried out by reaction and bringing into equilibrium the mixture of precursors, with a reducing gaseous atmosphere, in such a way as to bring the transition metal or metals to the desired valency level, the synthesis being carried out in the presence of a source of carbon called carbon conductor, which is subjected to pyrolysis. The materials obtained have excellent electrical conductivity as well as very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

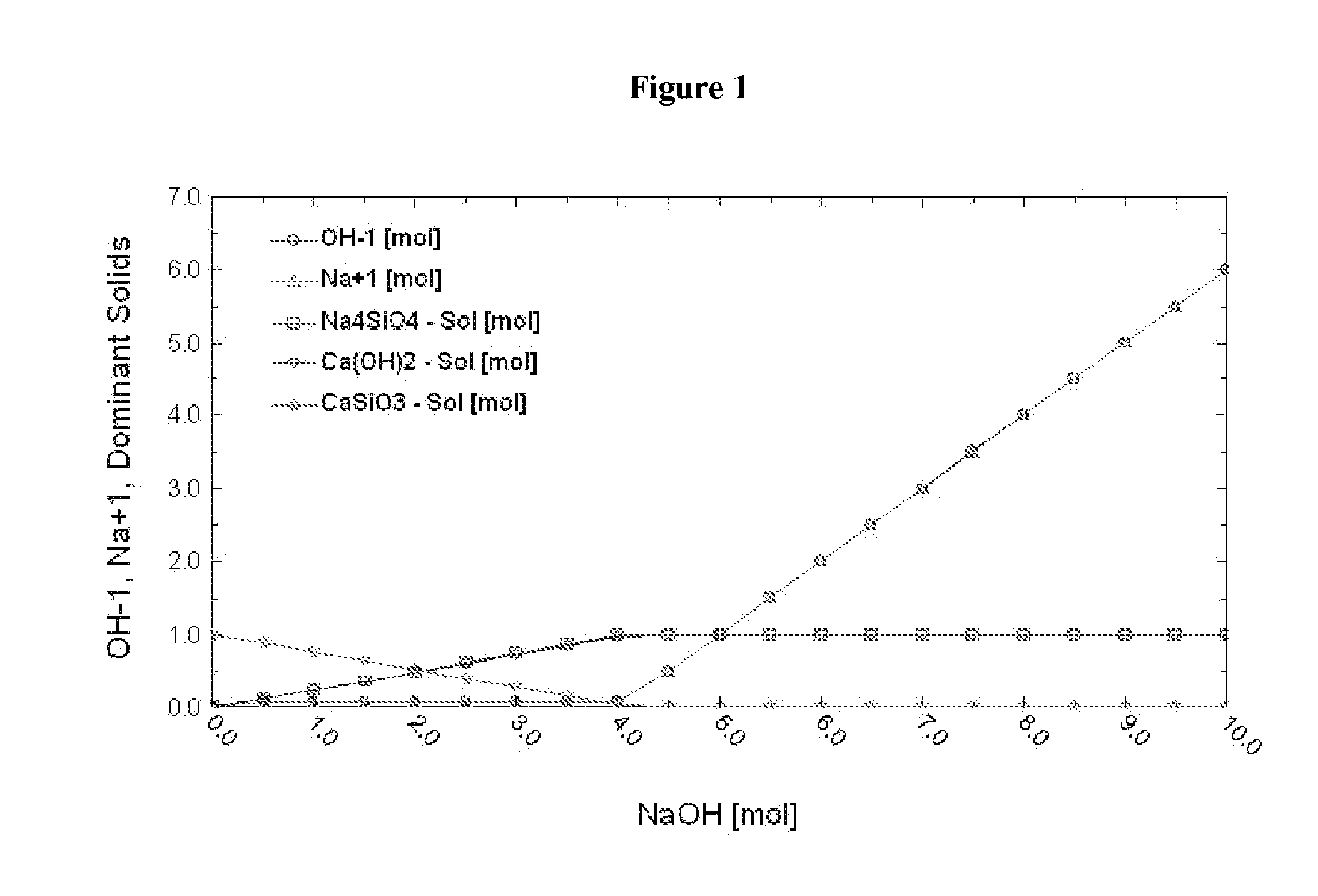

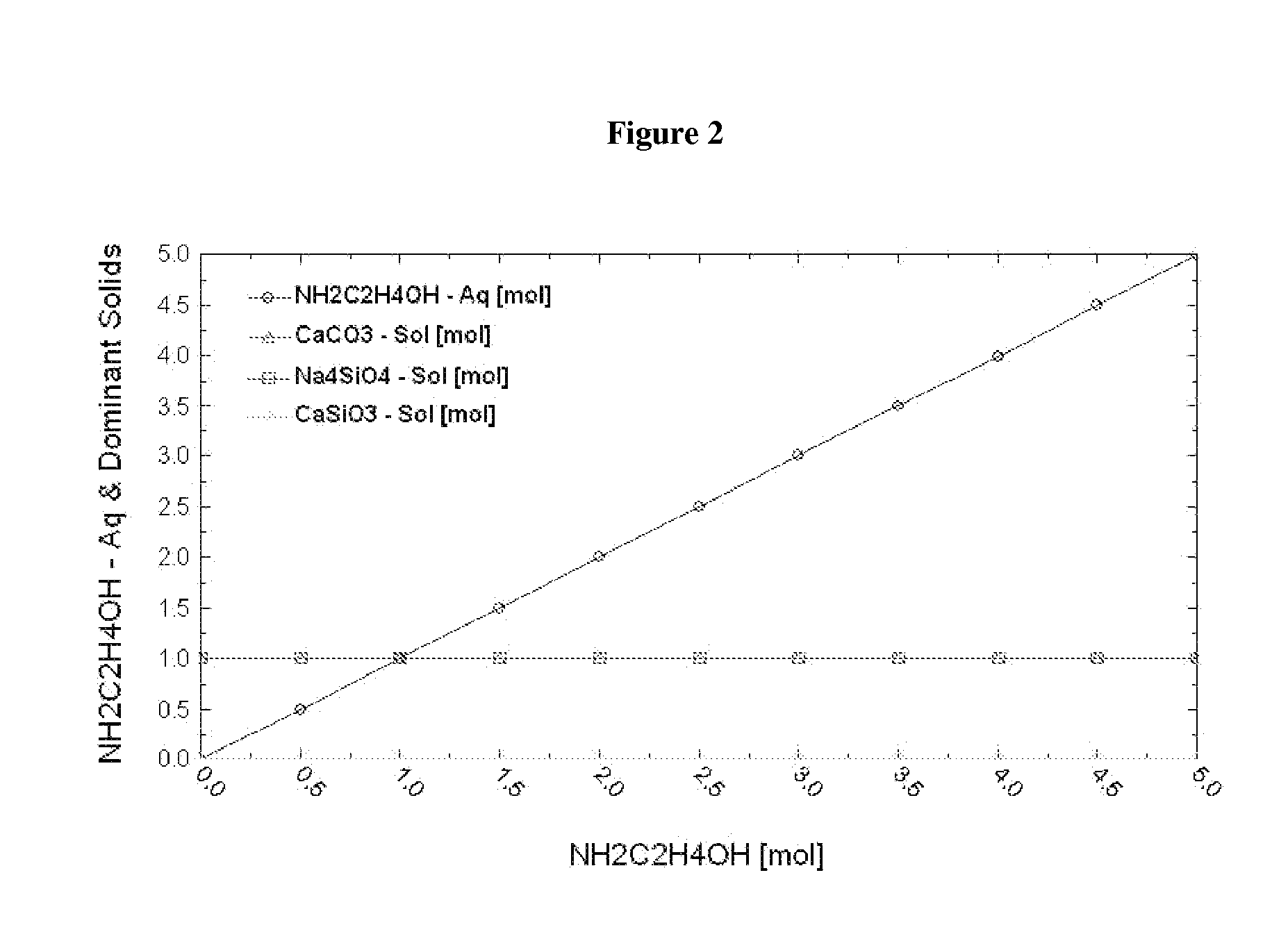

Sequestration of a gas emitted by an industrial plant

InactiveUS20110182799A1Eliminate needCalcium/strontium/barium carbonatesAmmonium nitratesNitrogenNitrogen gas

A method of sequestering a multi-element gas emitted by an industrial plant is described herein, the method comprising: contacting a solution, including a first reactant comprising a multi-element gas emitted by an industrial plant and at least one gas absorber comprising nitrogen, for example ammonia or an amine, with a solid, including a second reactant, under conditions that promote a reaction between the first reactant and the second reactant to provide a first product, which incorporates one or more elements of the multi-element gas, thereby sequestering the multi-element gas.

Owner:RUTGERS THE STATE UNIV

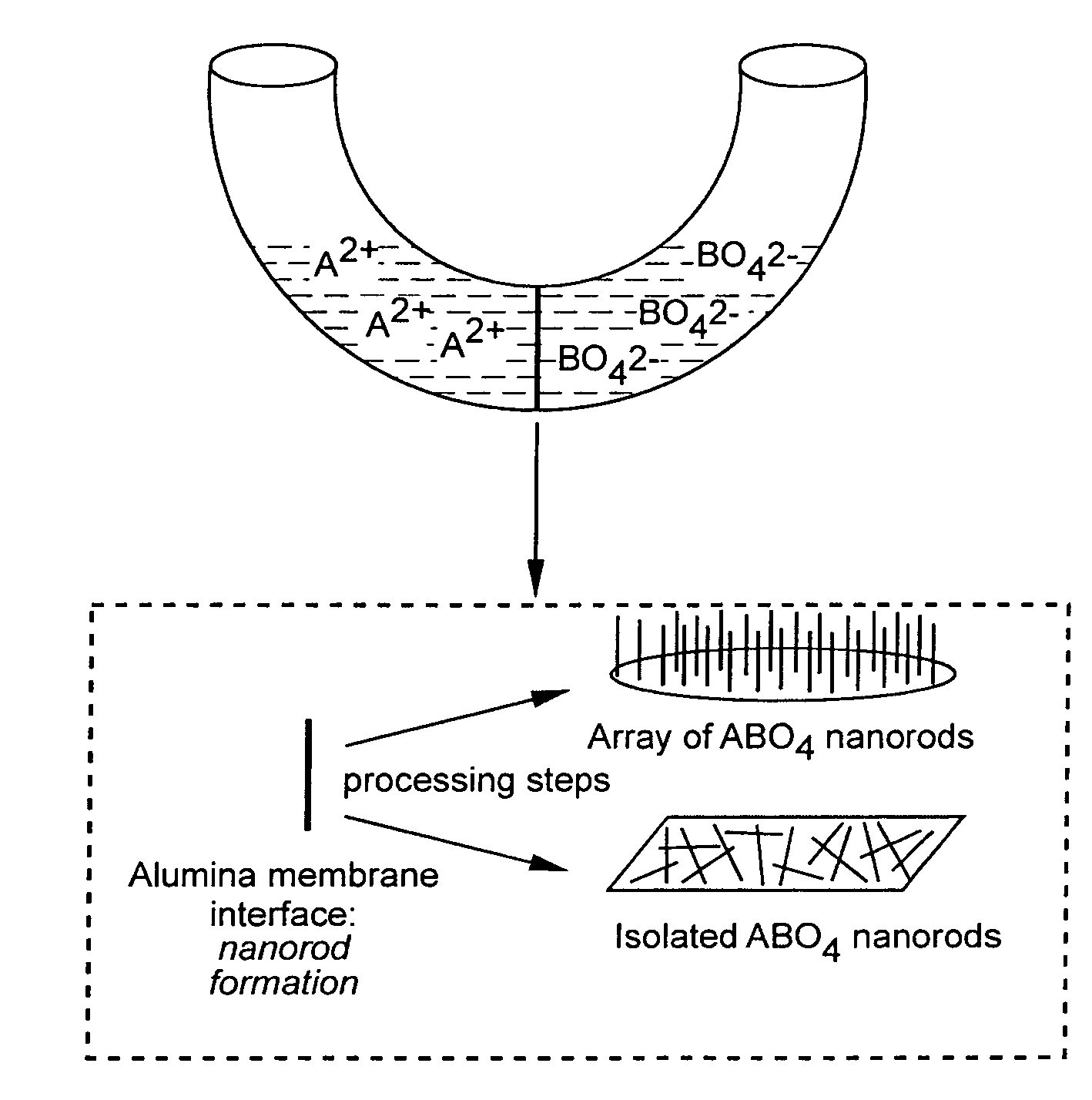

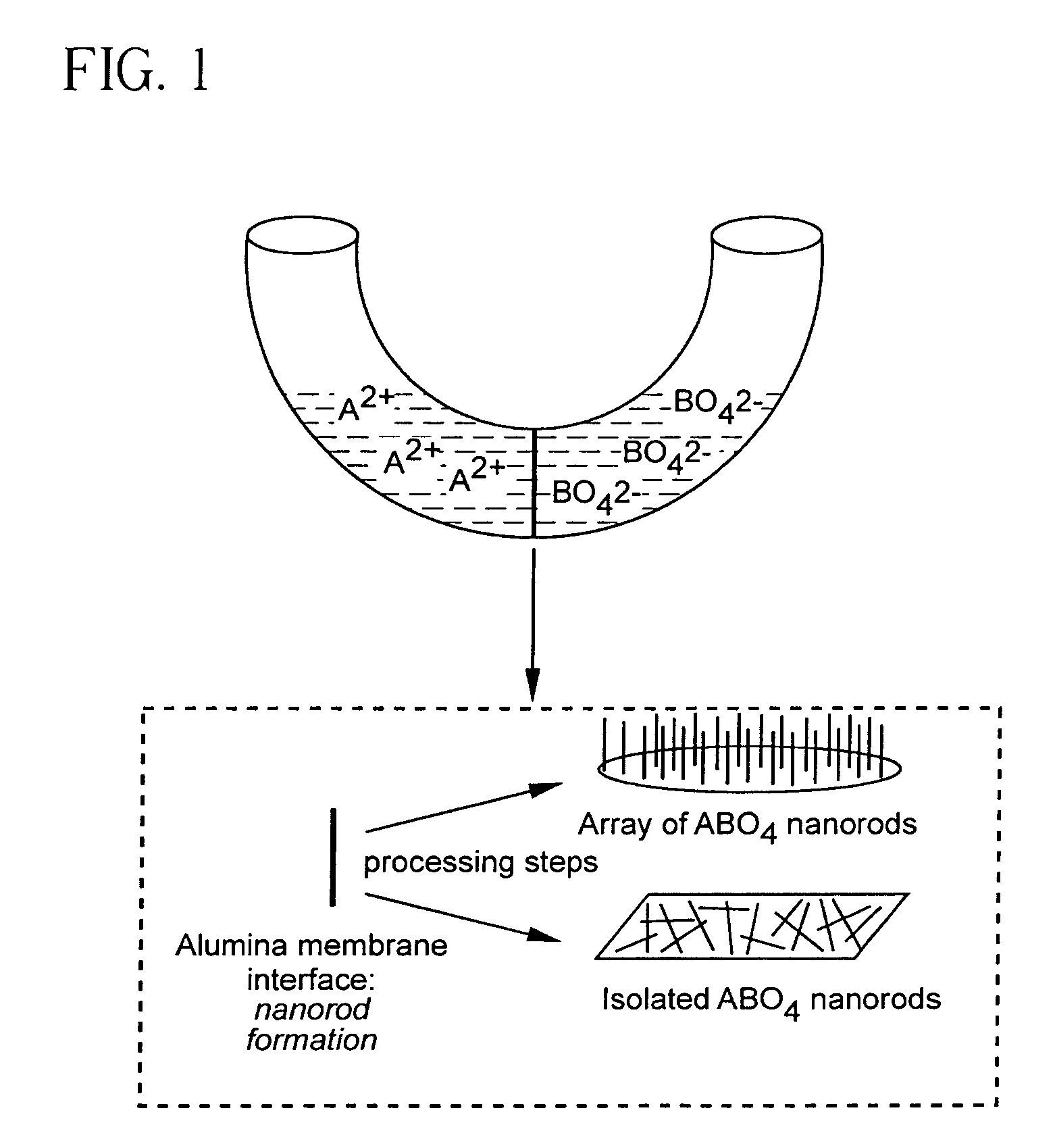

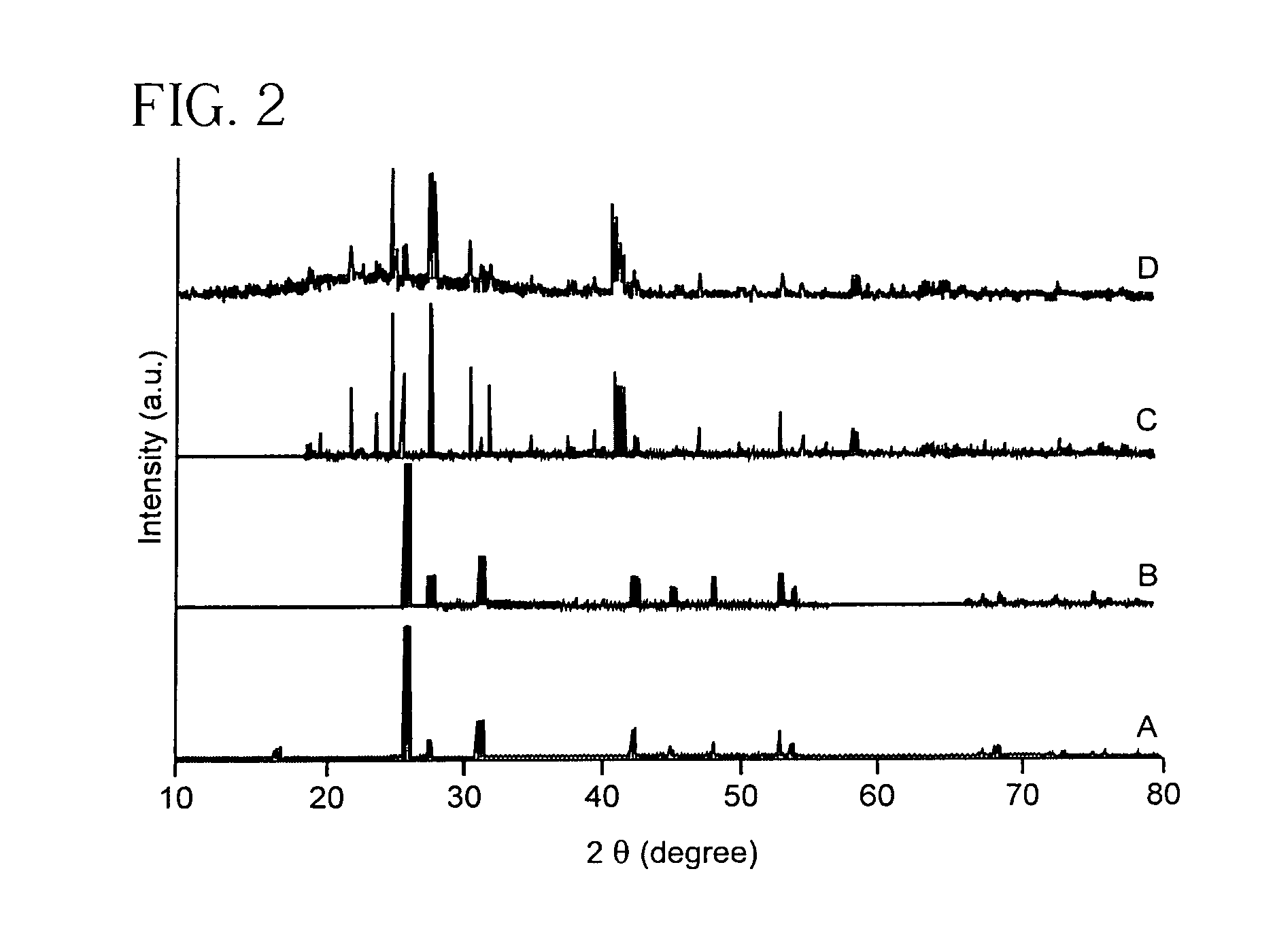

Metal oxide and metal fluoride nanostructures and methods of making same

InactiveUS20070113779A1Easy to controlOvercomes shortcomingMercury oxidesAlkali metal oxides/hydroxidesSingle crystalNanostructure

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

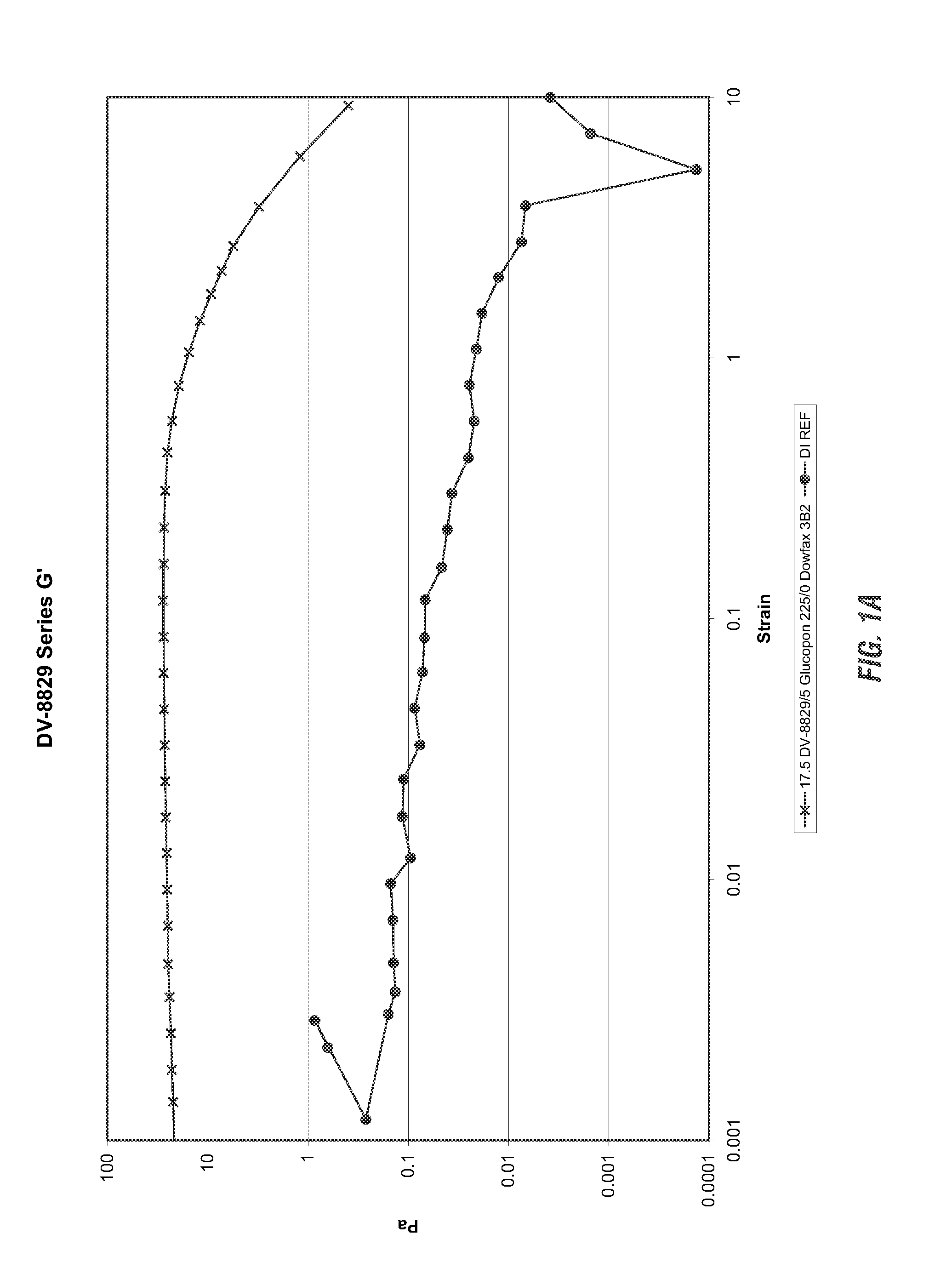

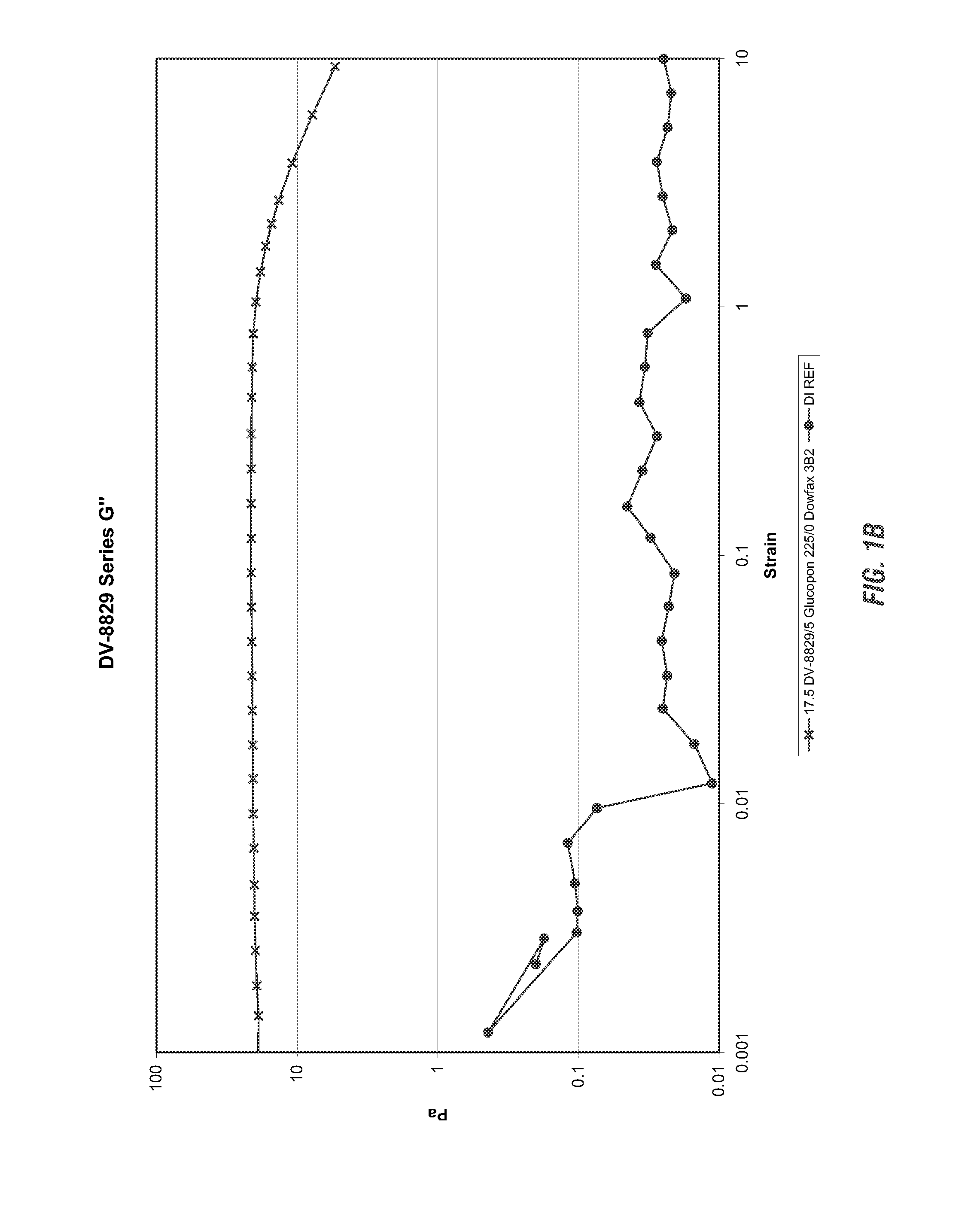

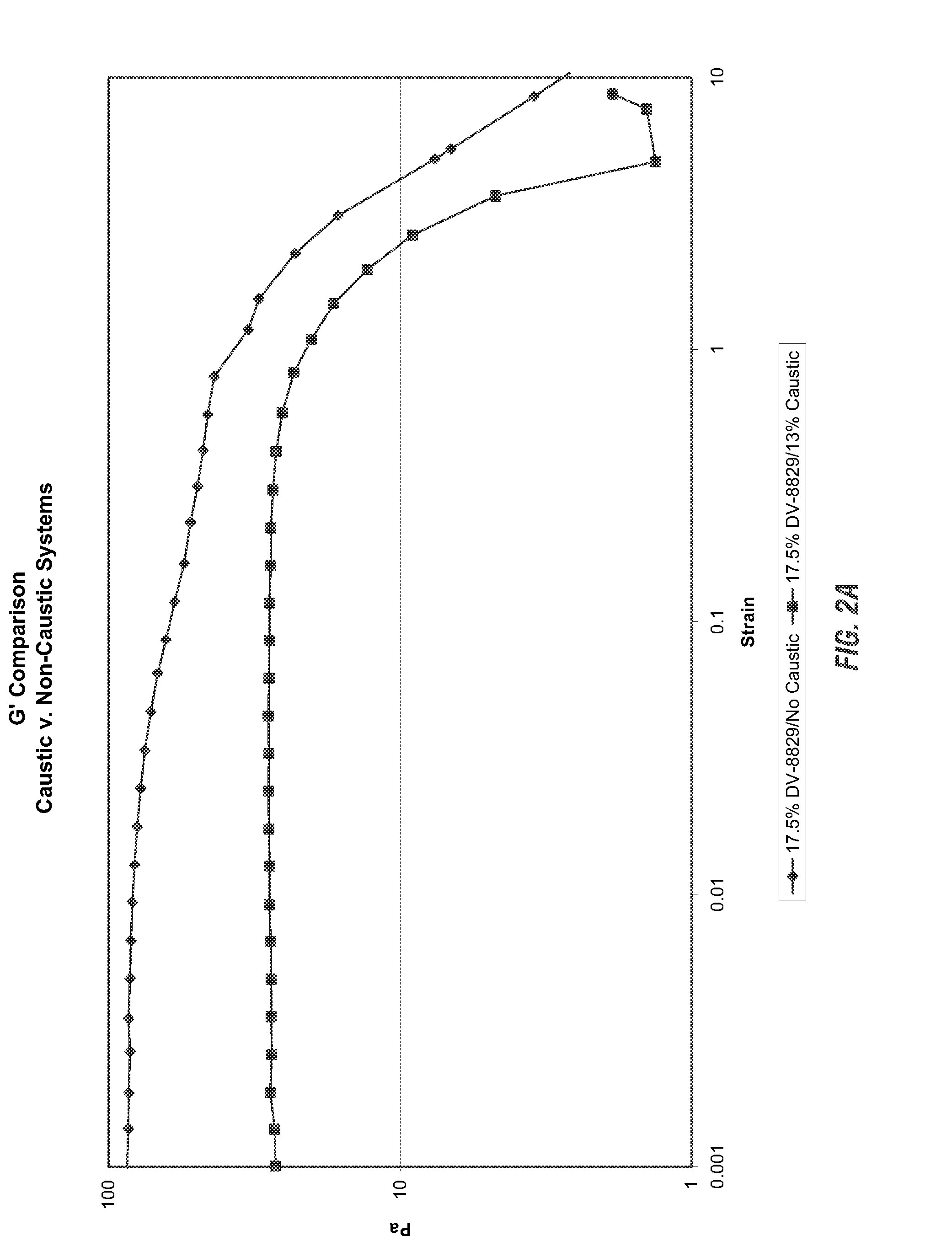

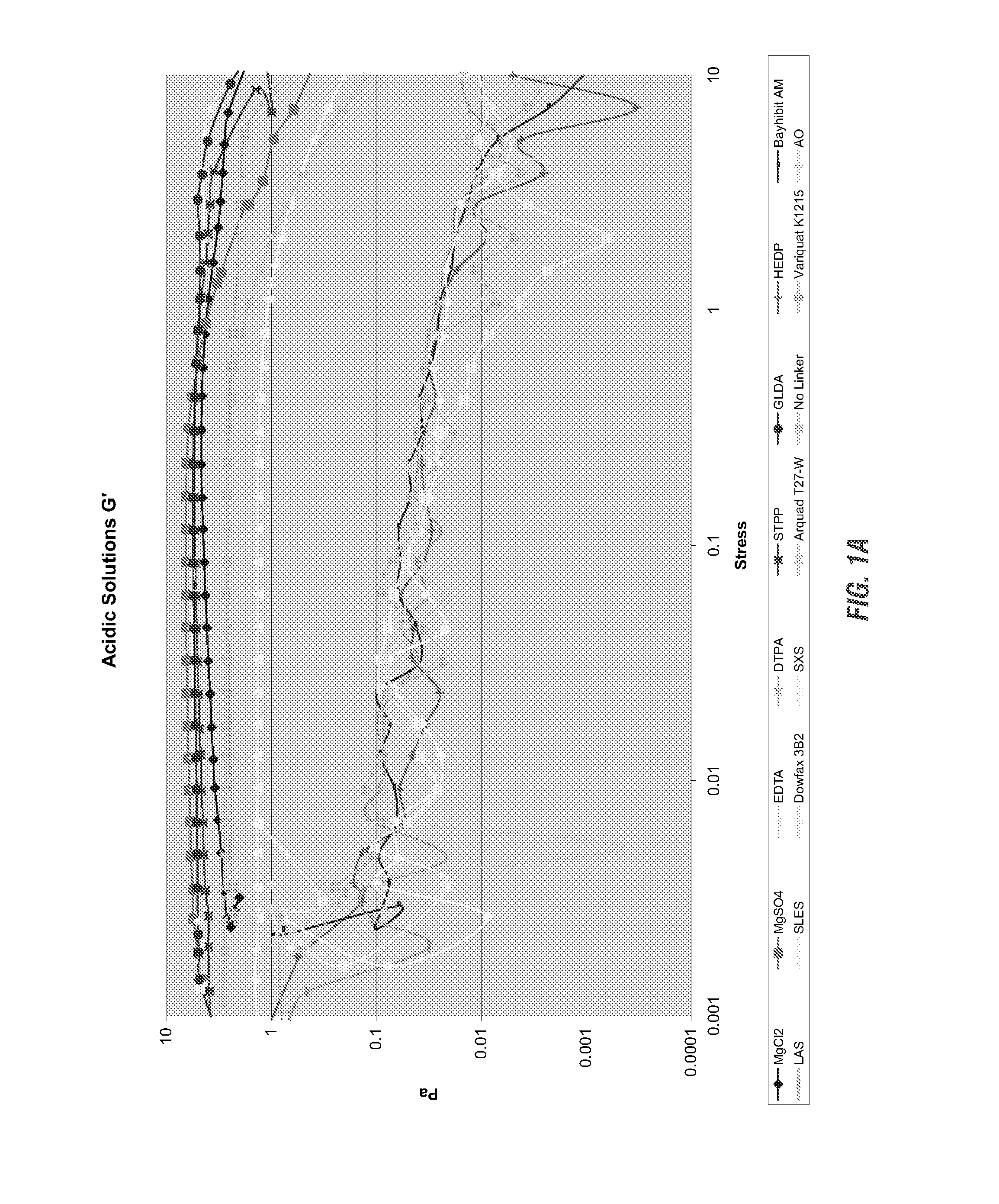

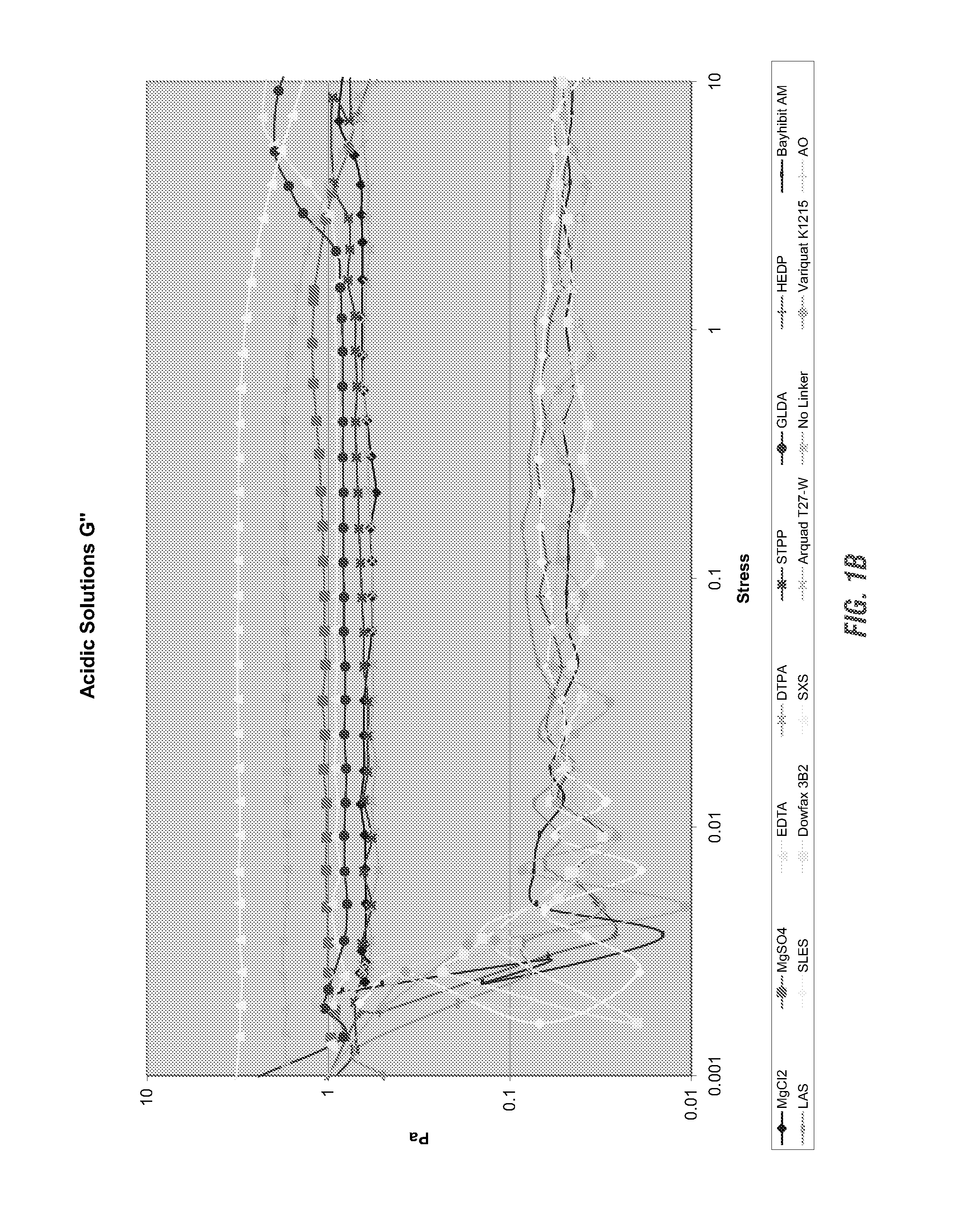

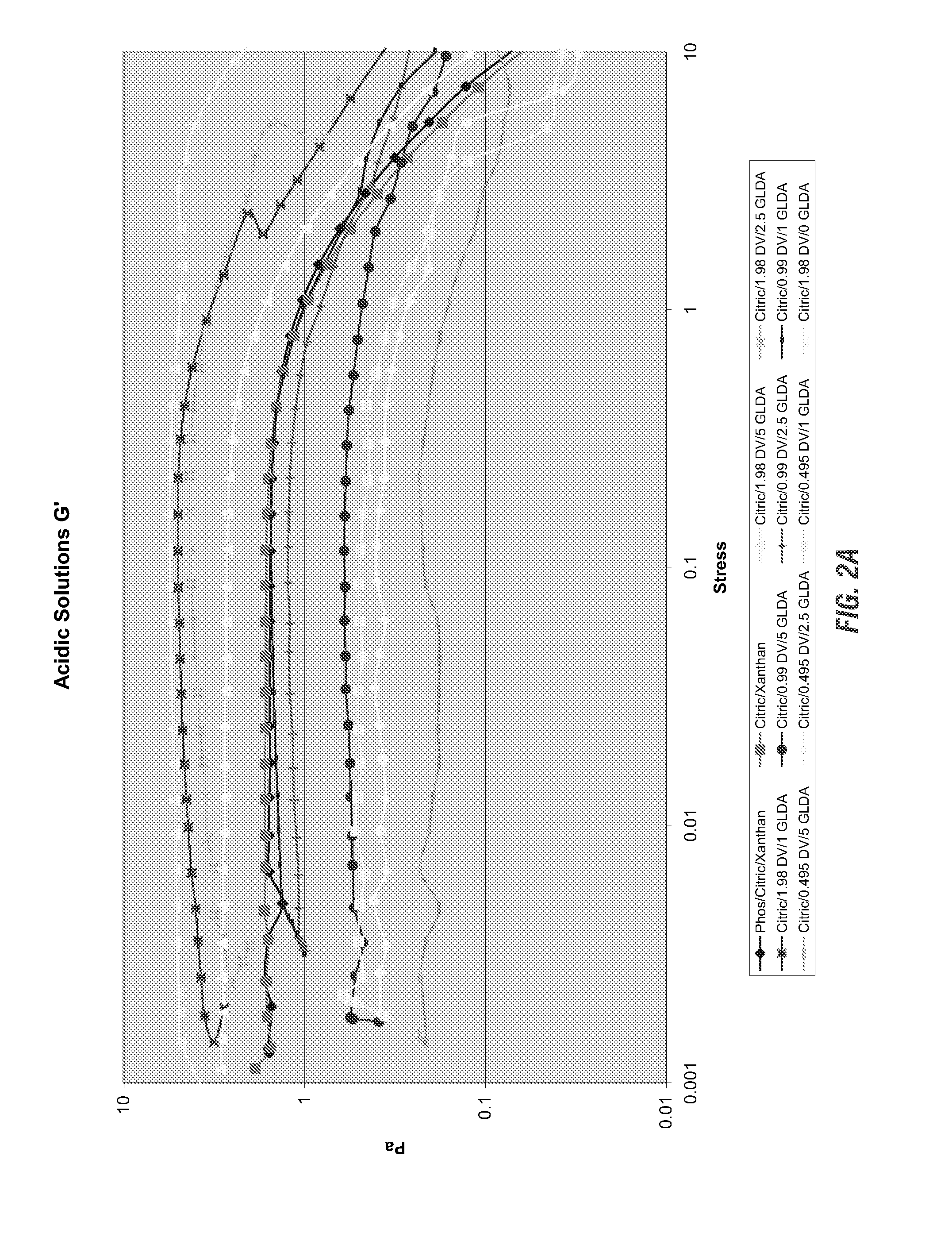

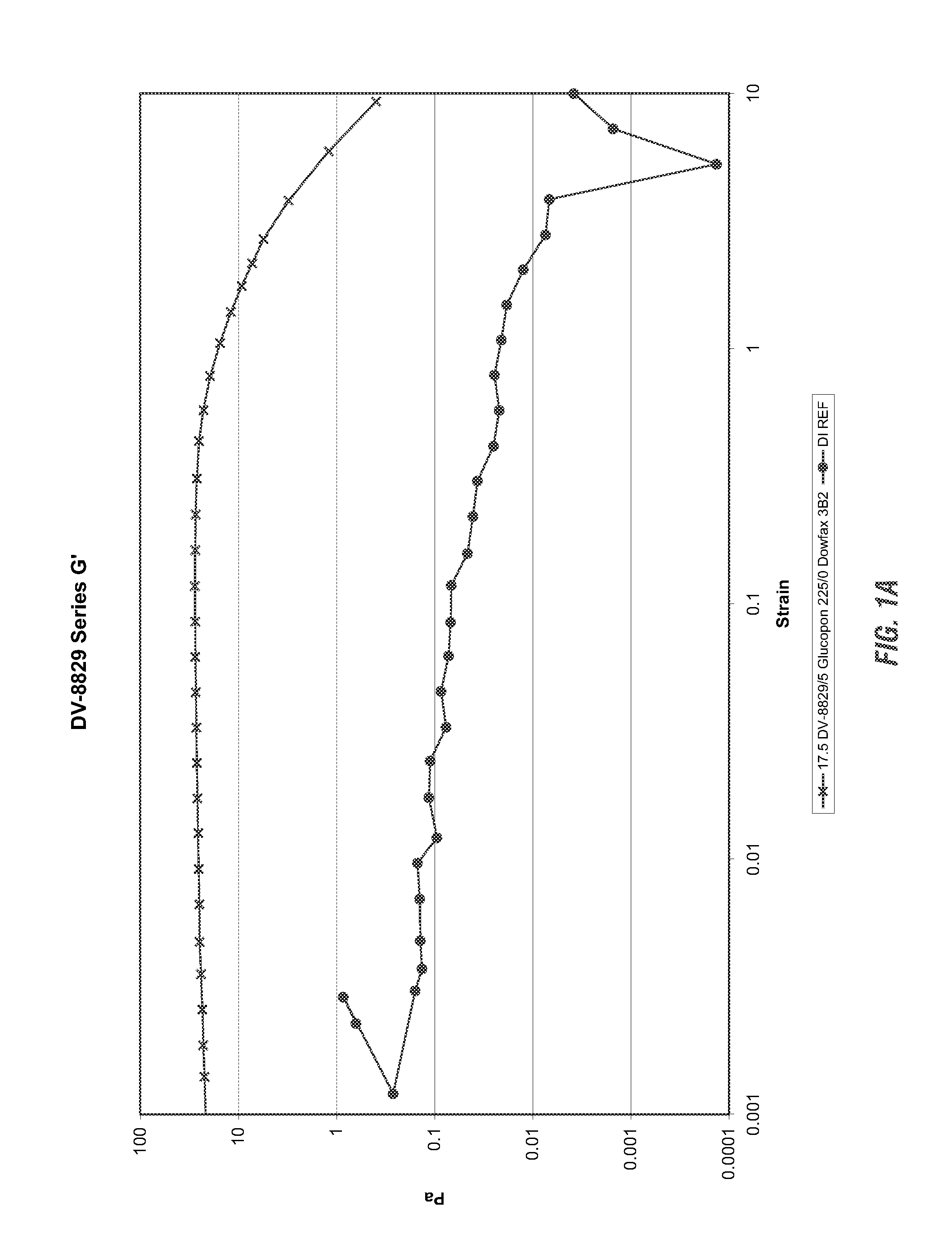

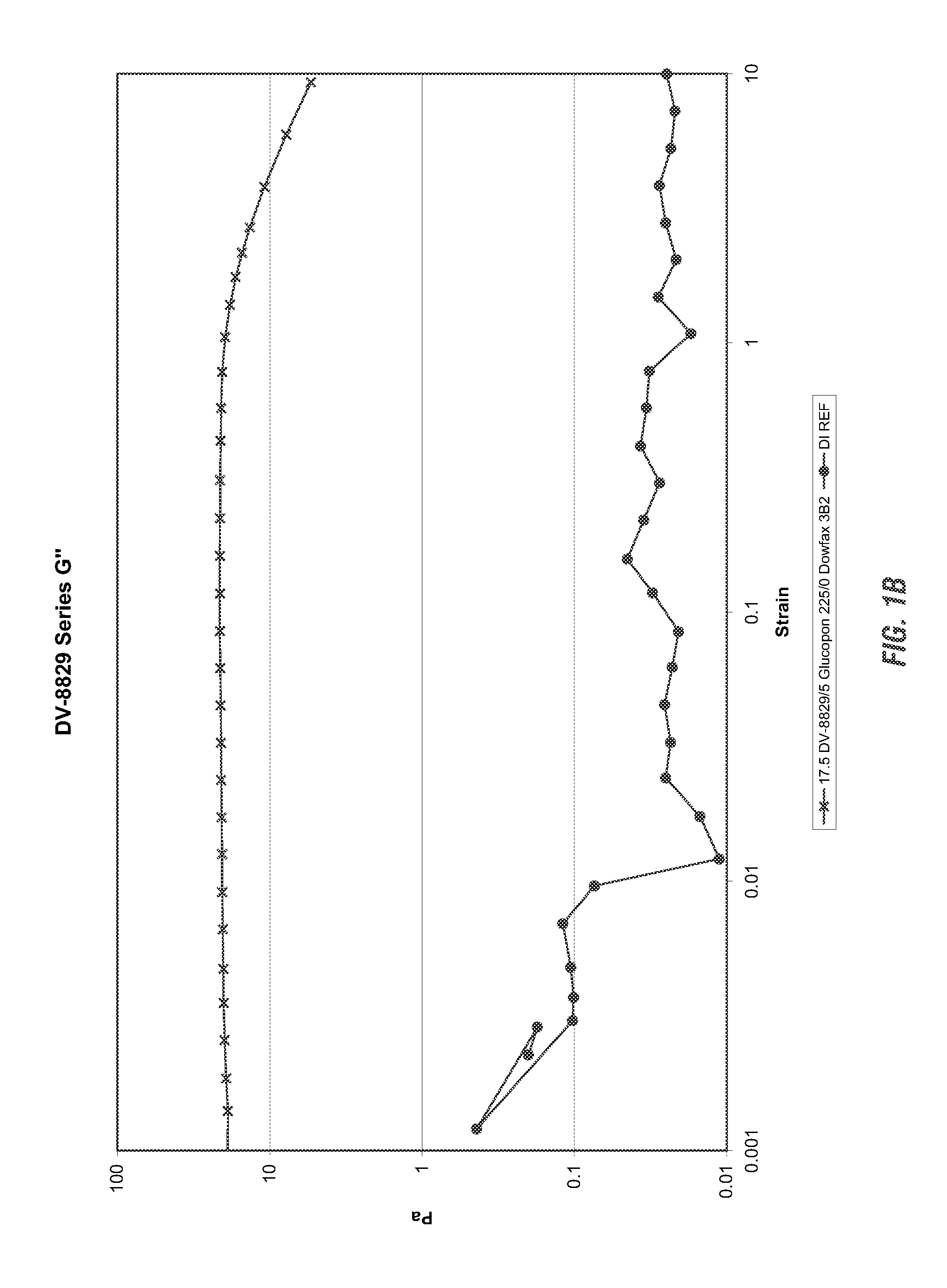

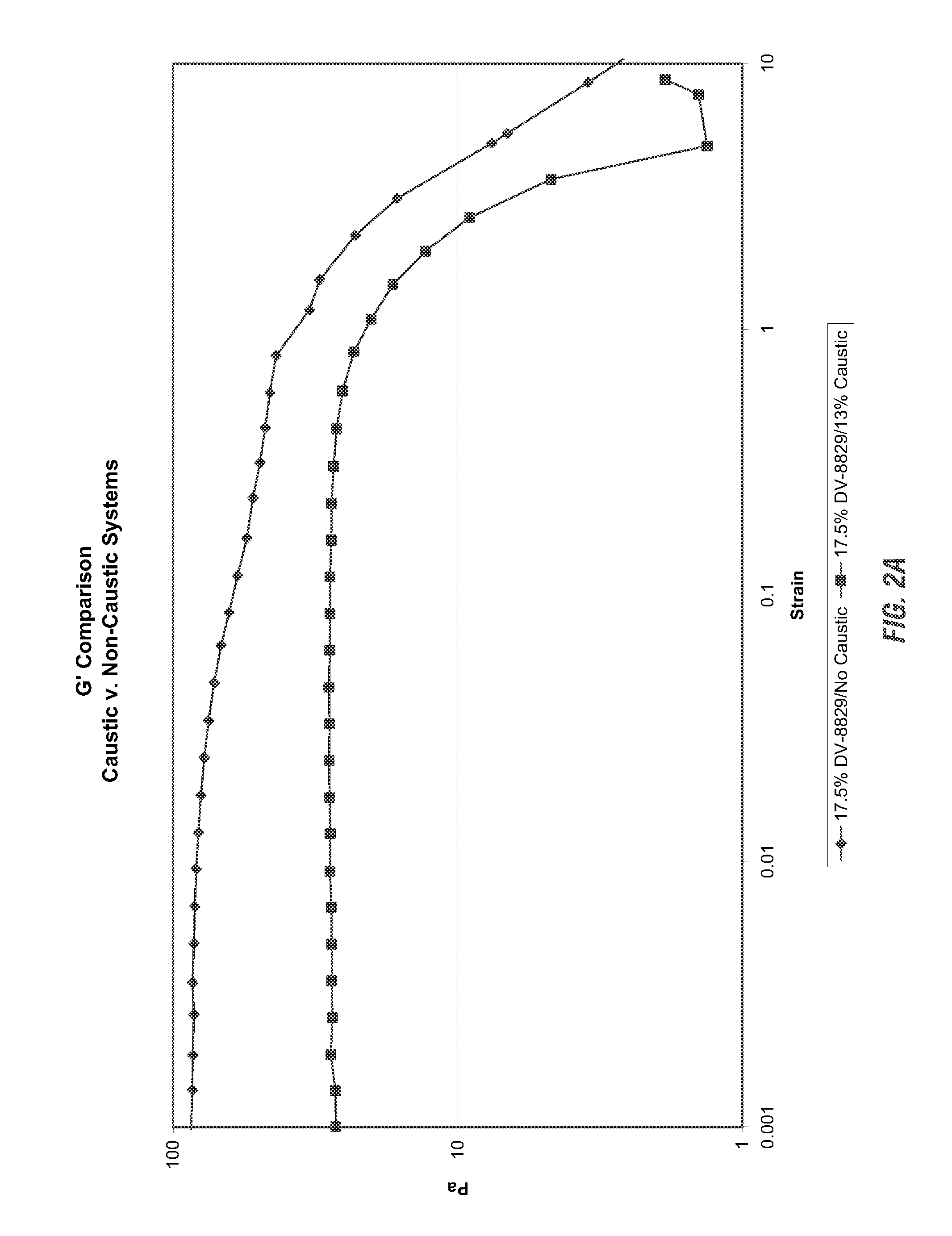

Viscoelastic surfactant based cleaning compositions

ActiveUS20140148371A1Improve performanceAdditional componentInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsViscoelasticitySURFACTANT BLEND

Alkaline or neutral viscoelastic cleaning compositions are disclosed which use non polymer thickening agents. According to the invention, cleaning compositions have been developed using viscoelastic surfactants in a neutral, acidic or alkaline cleaning formulations. These provide the dual benefit of thickening as well as an additional cleaning, thereby improving performance. Applicants have also identified several pseudo linking agents which when, used with viscoelastic surfactants provide viscoelasticity in alkaline cleaning compositions.

Owner:ECOLAB USA INC

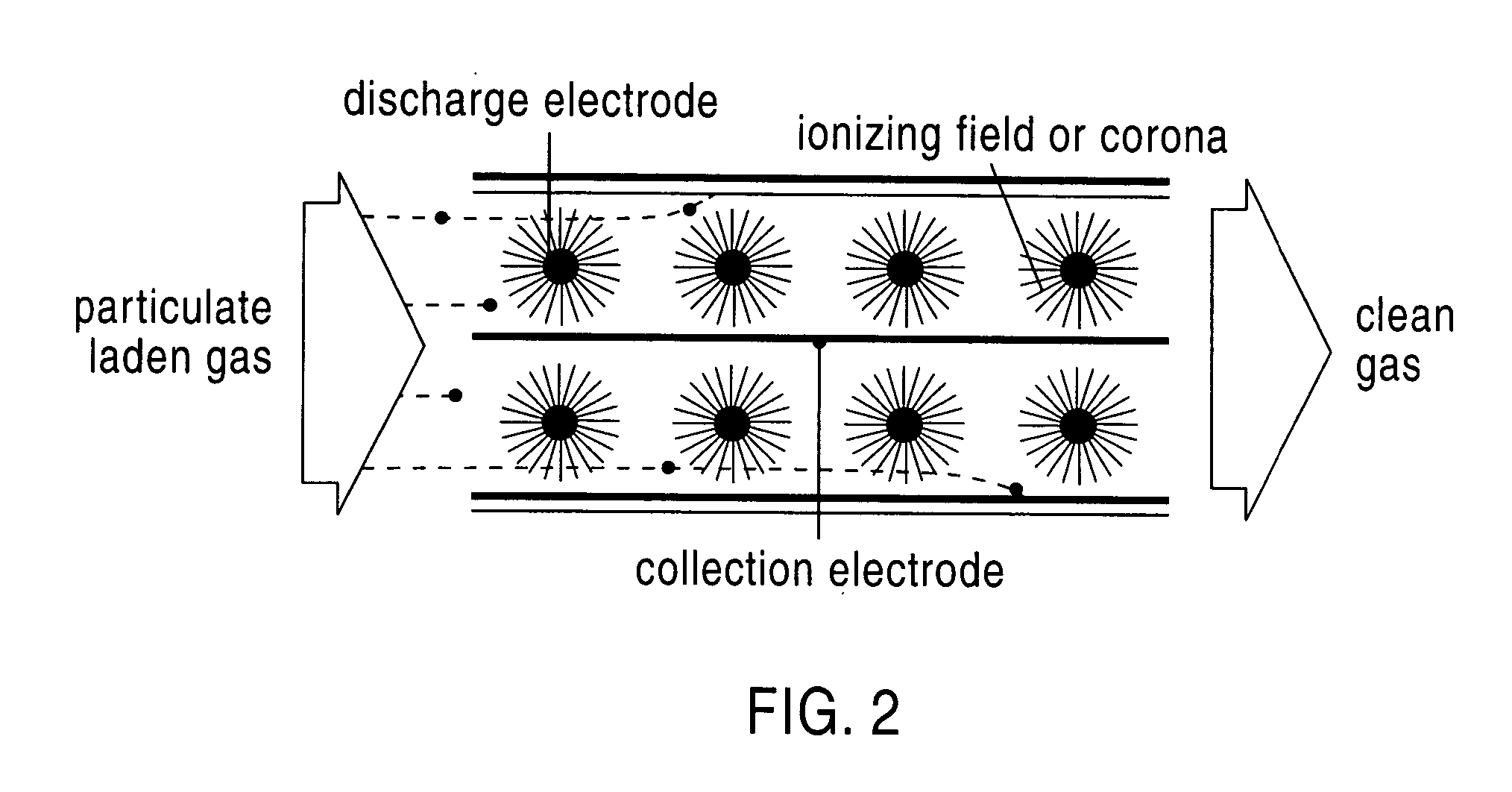

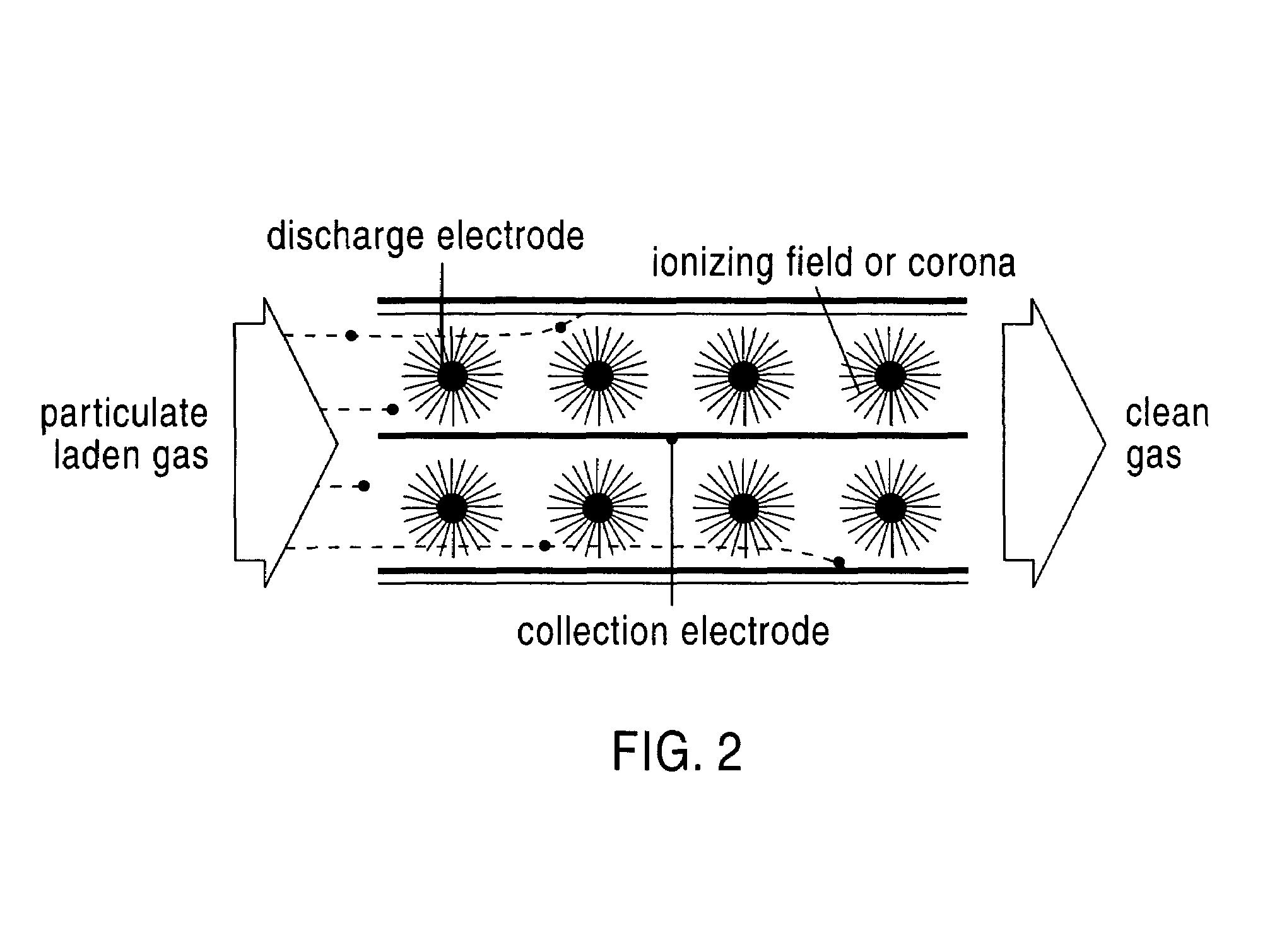

Sorbents for Removal of Mercury From Flue Gas Cross Reference To Related Applications

Systems are disclosed for making and using micro-porous particulates at least partially composed of metal sulfides, particularly alkaline earth metal and transition metal sulfides, as sorbents for removal of mercury from flue gas. Calcium sulfide micro-porous powders derived from the high temperature reduction of calcium sulfate and calcium sulfite are disclosed to be reactive substrates for a group of sorbents for adsorption of mercury from coal combustion flue gases produced by the utilities industry, as well as from natural gas and gaseous and liquid hydrocarbons. The sorbents are useful for cost-effectively adsorbing elemental mercury and oxidized mercury species such as mercuric chloride from flue gases, including those containing acid gases (e.g., SO.sub.2, NO and NO.sub.2, and HCl), over a wide range of temperatures.

Owner:CHEM PROD CORP

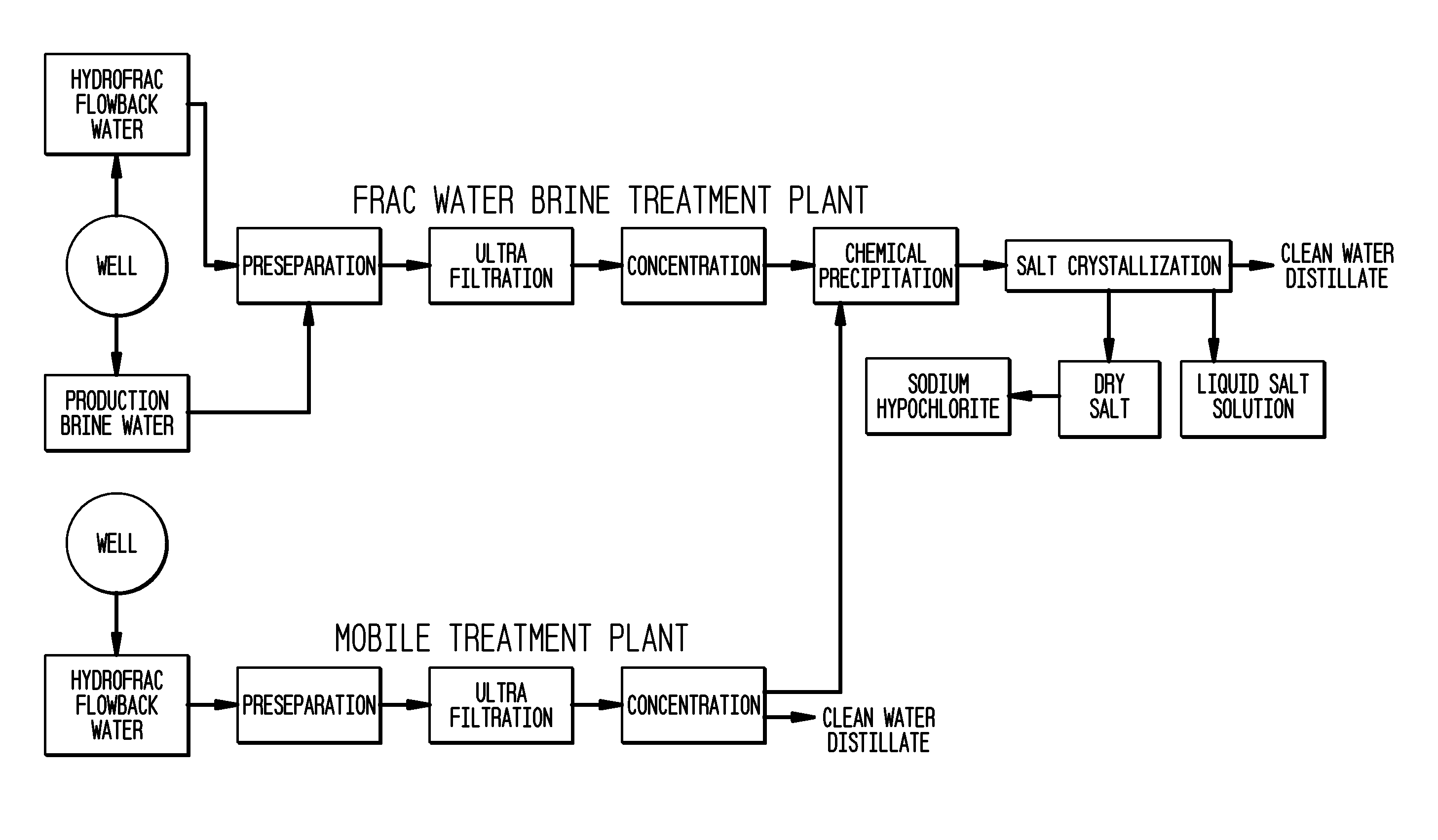

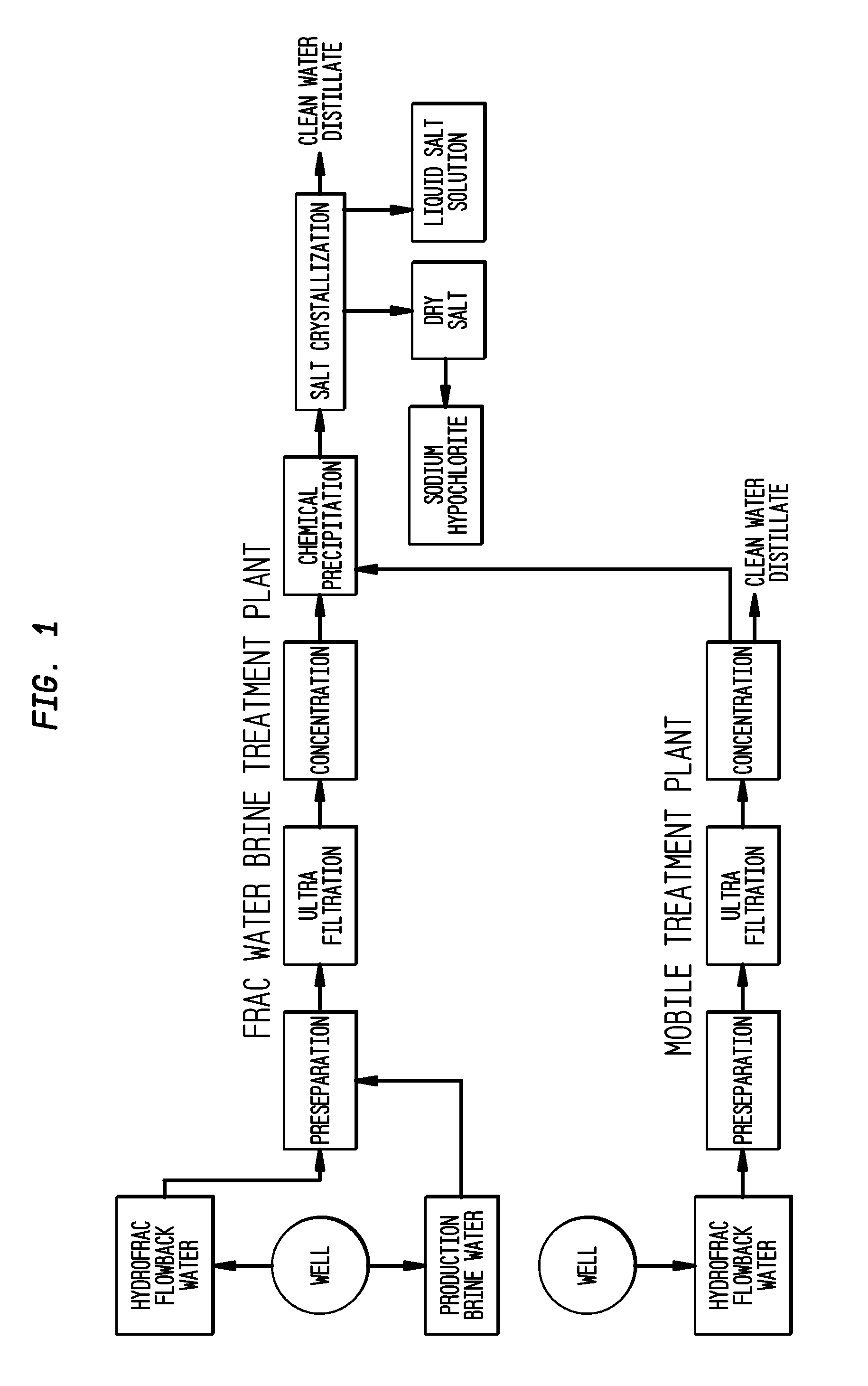

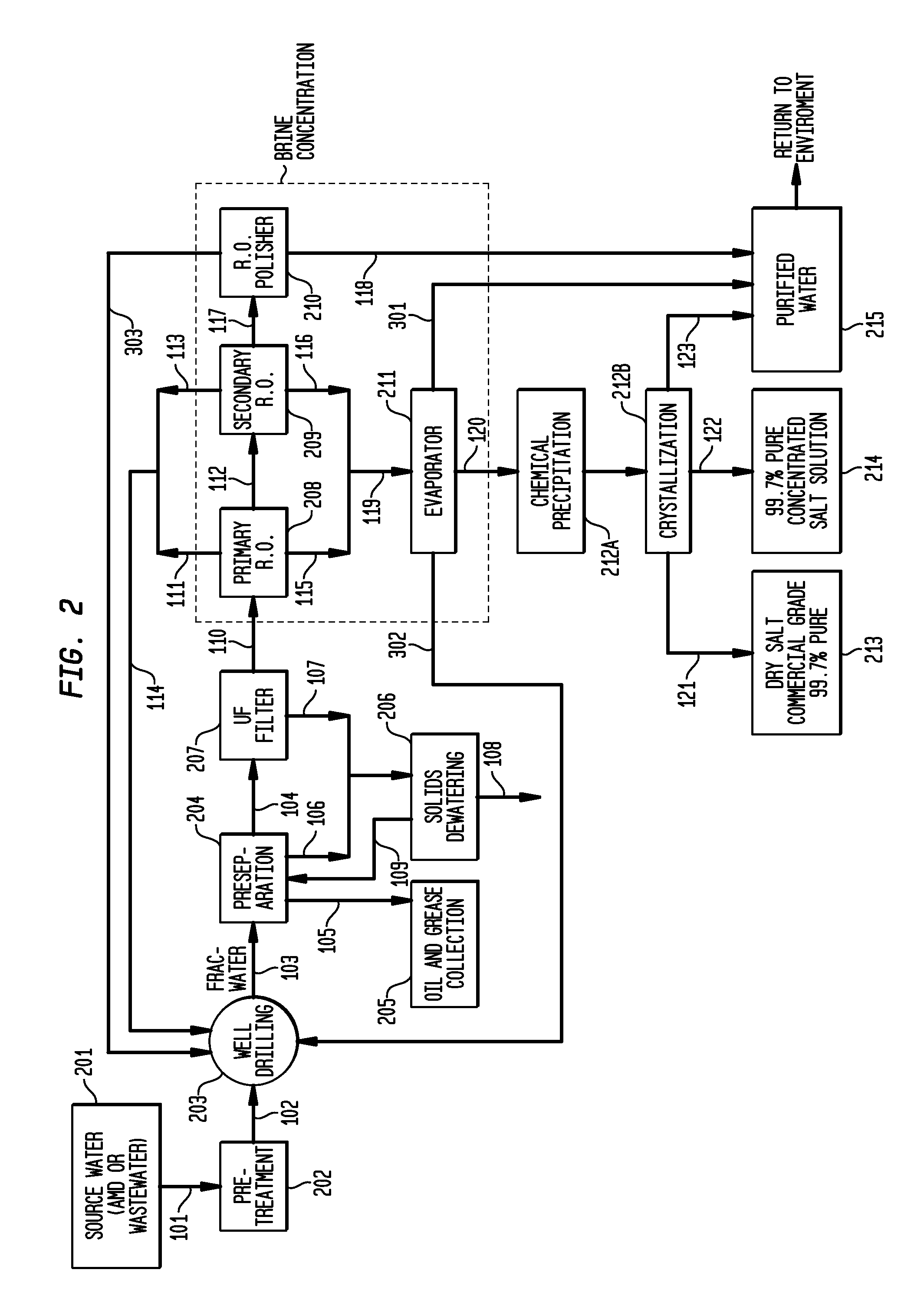

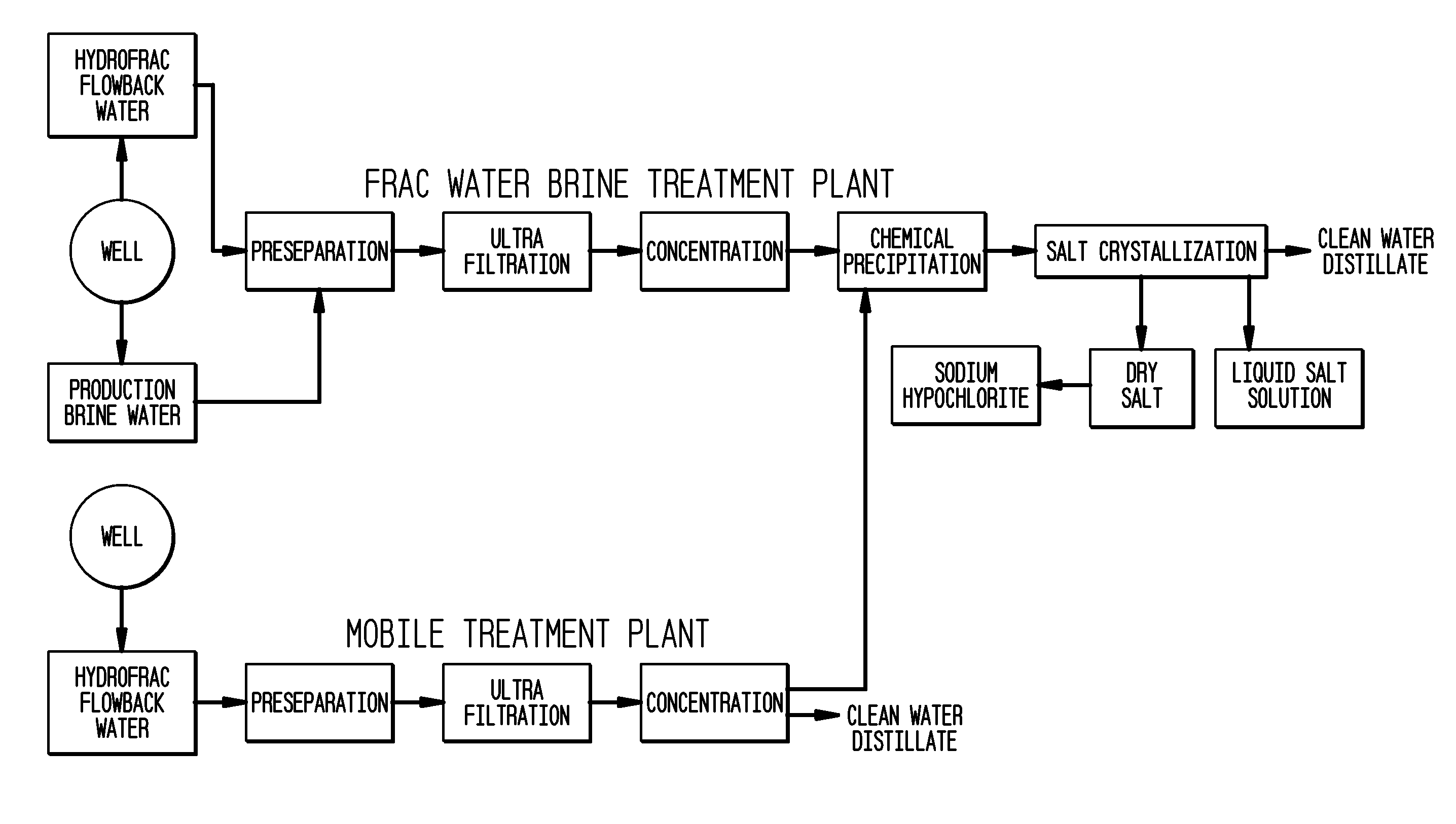

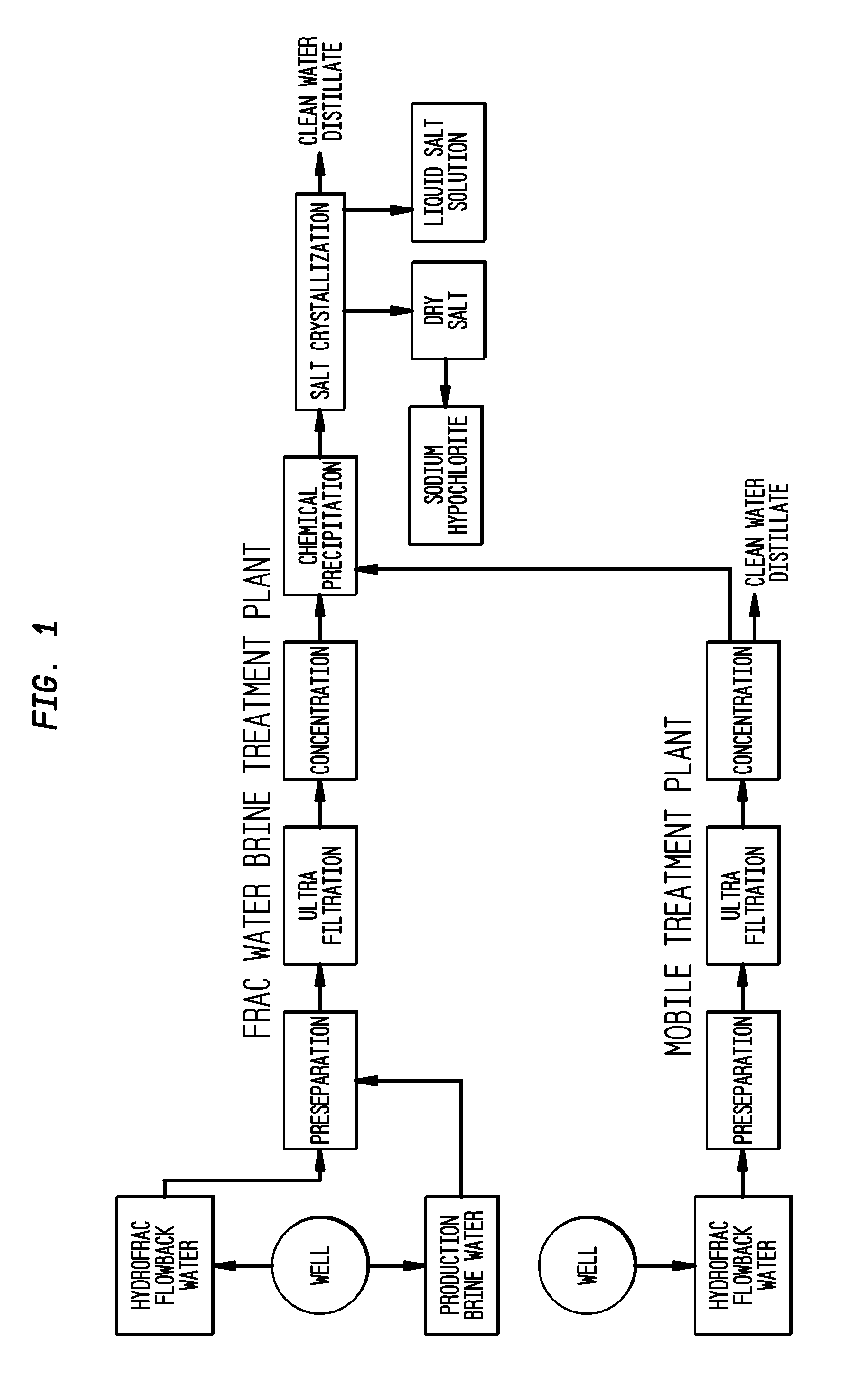

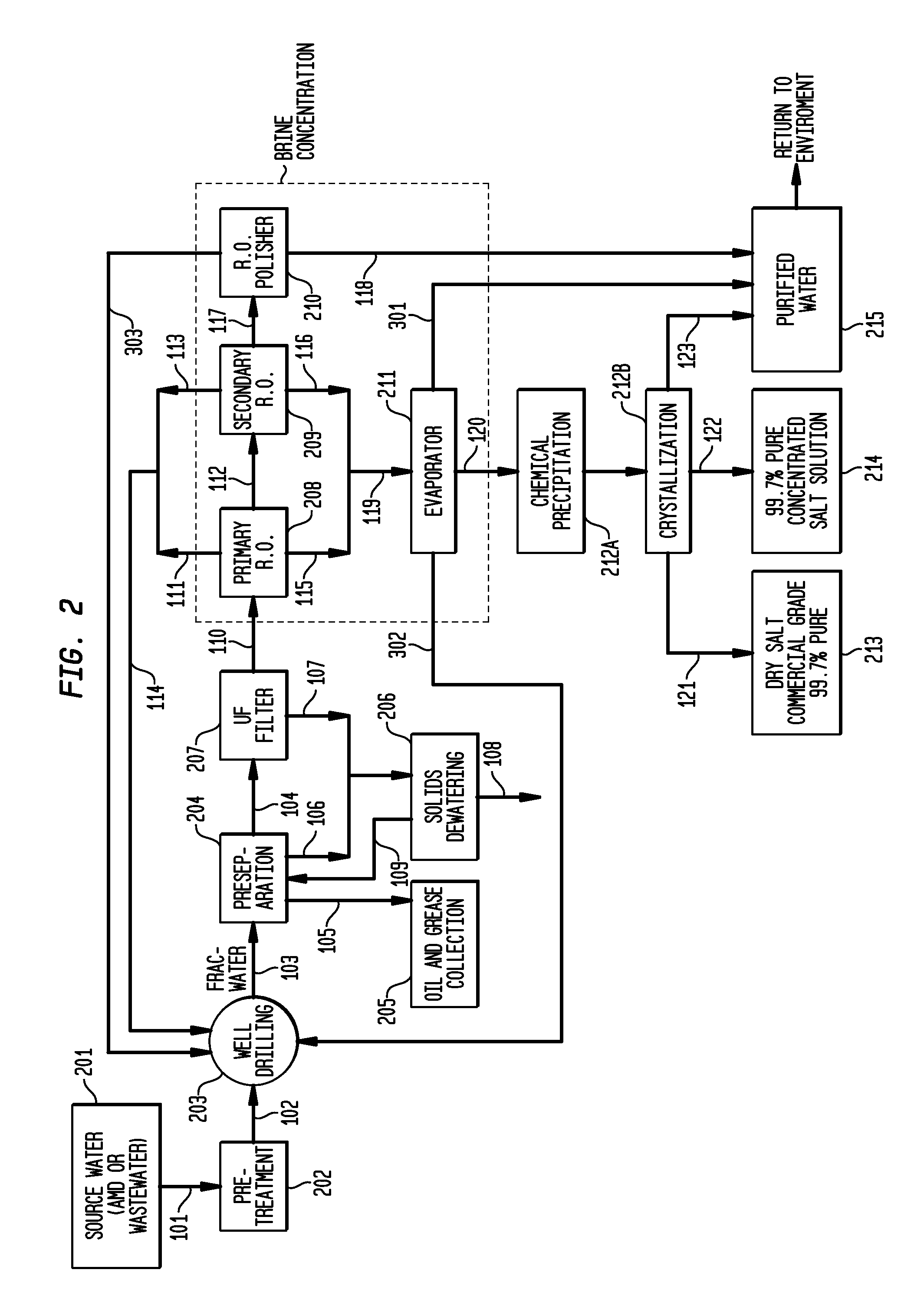

Method of making pure salt from FRAC-water/wastewater

ActiveUS8158097B2Yield maximizationQuality improvementCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesWater useParticulates

The present invention relates to a method for making pure salt comprises recapturing post-drilling flowback water from hydro-fracturing; removing oil from the flowback water; filtering the flowback water using an ultra filter with a pore size of about 0.1 microns or less to remove solid particulates and large organic molecules, such as benzene, ethylbenzene, toluene, and xylene, from the water; concentrating the flowback water to produce a brine that contains from about 15 wt % to about 40 wt % of salt relative to the total weight of the flowback brine; performing one or more chemical precipitation process using an effective amount of reagents to precipitate out the desired high quality commercial products, such as, barium sulfate, strontium carbonate, calcium carbonate; and crystallizing the chemically treated and concentrated flowback brine to produce greater than 99.5% pure salt products, such as sodium and calcium chloride.

Owner:FRACPURE HLDG

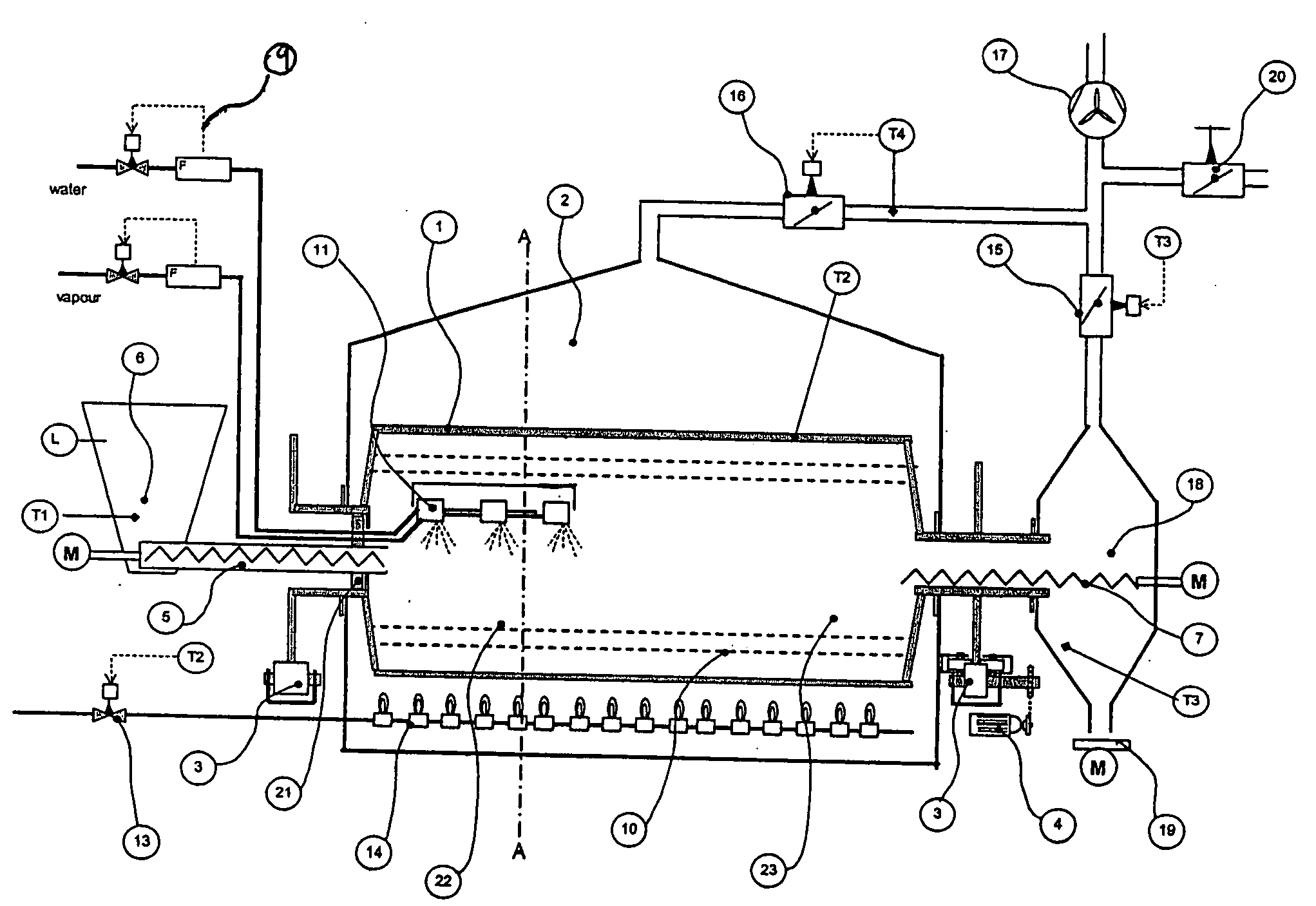

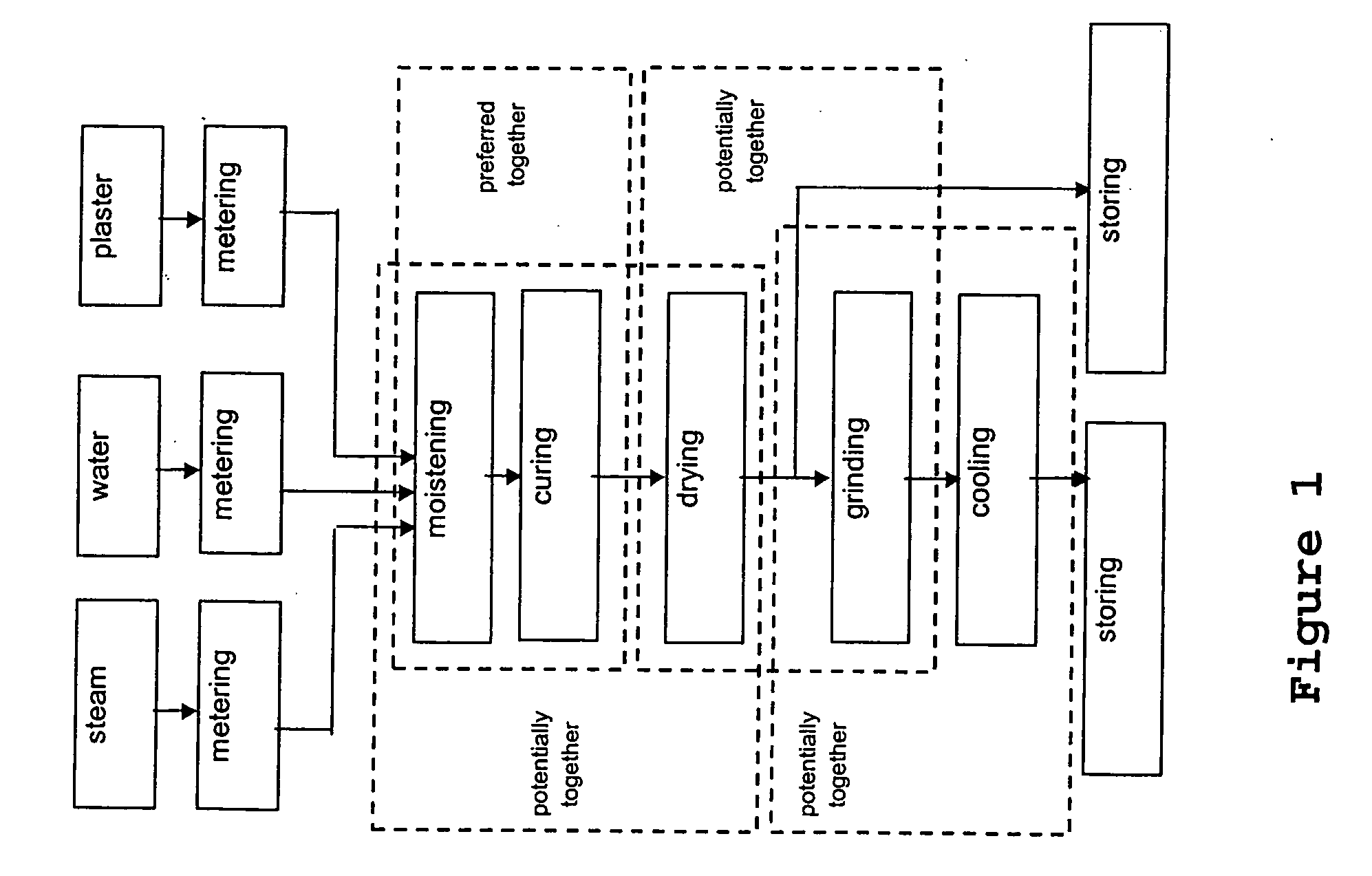

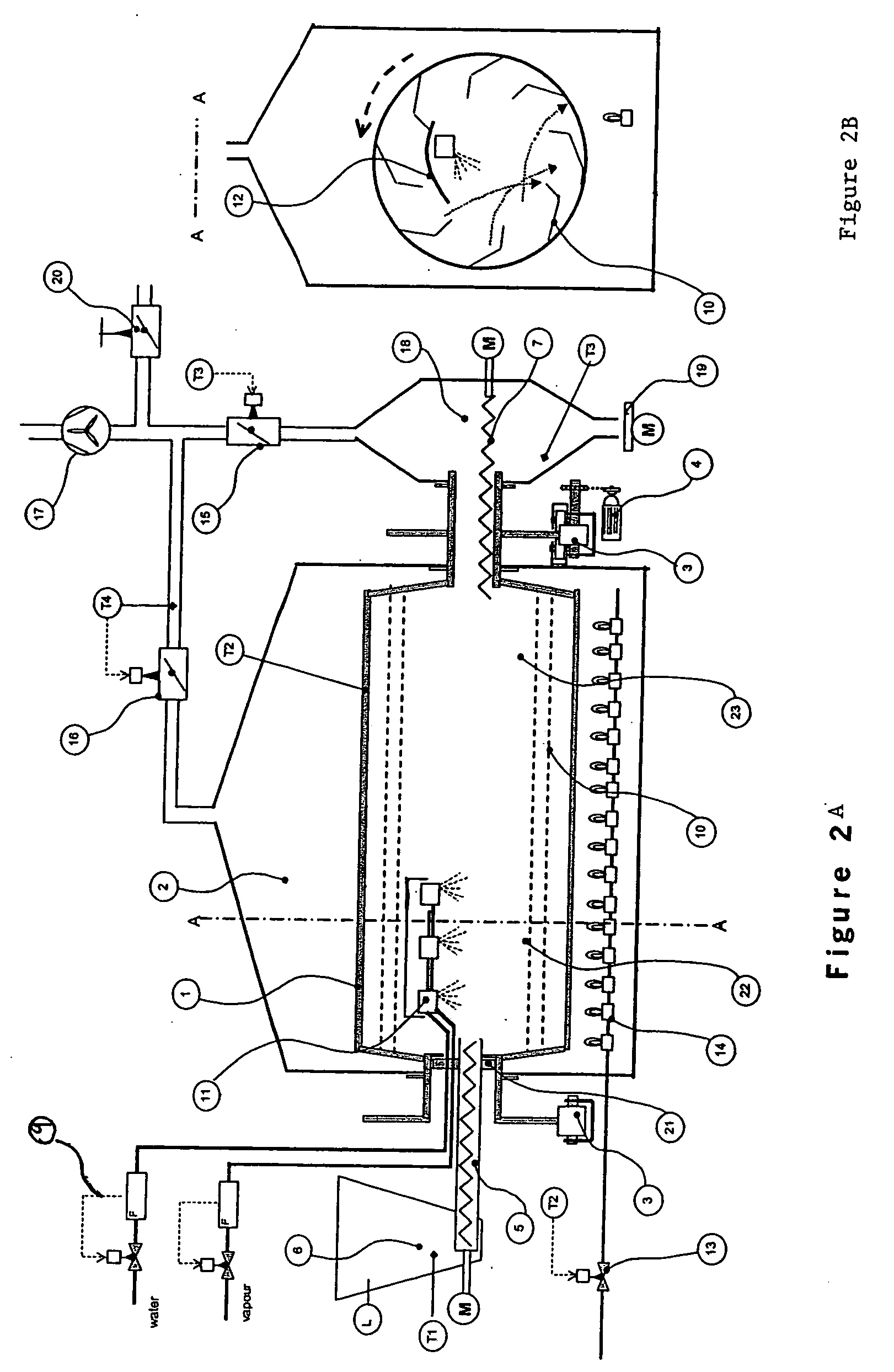

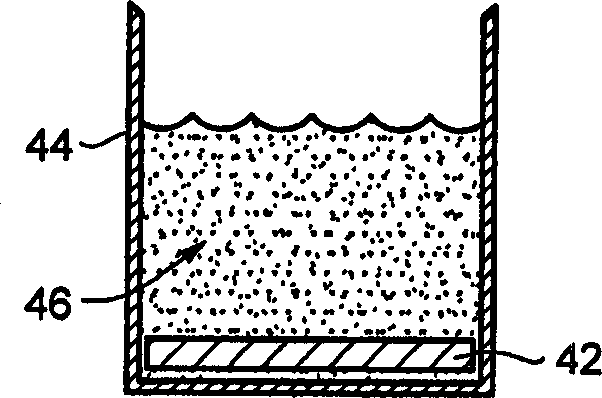

Method and apparatus for stabilizing plaster

ActiveUS20050152827A1Avoid accumulationRotating receptacle mixersTransportation and packagingRotating drumAtmosphere

The invention provides a process for stabilizing plaster and an apparatus for implementing the moistening part of the process. The process comprises the following steps: a) providing a heated HH-plaster preferably at temperatures over 100° C.; b) feeding the hot plaster in a moistening device having walls heated to at least 100° C.; c) injecting water and / or steam into the moistening device in conditions that such not yet moistened surfaces of the plaster are exposed to the injected water and / or steam; d) maintaining an atmosphere in the moistening device at a level of the dew point in the range of 75 to 99° C.; e) feeding the moistened blend into a curing device; f) maintaining an atmosphere in the curing device above 75° C. for at least 3 minutes; g) feeding the moistened and cured blend into a drying device; and h) drying said moistened and cured blend. The invention also provides an apparatus for moistening β-hemihydrate plaster comprising a rotating drum with lifting blades inside where all walls in contact with the product are externally heated at a temperature above 100 ° C . The invention finally provides specific uses for plasters obtainable by the process of the invention.

Owner:CONTINENTAL BUILDING PROD OPERATING COMPANY

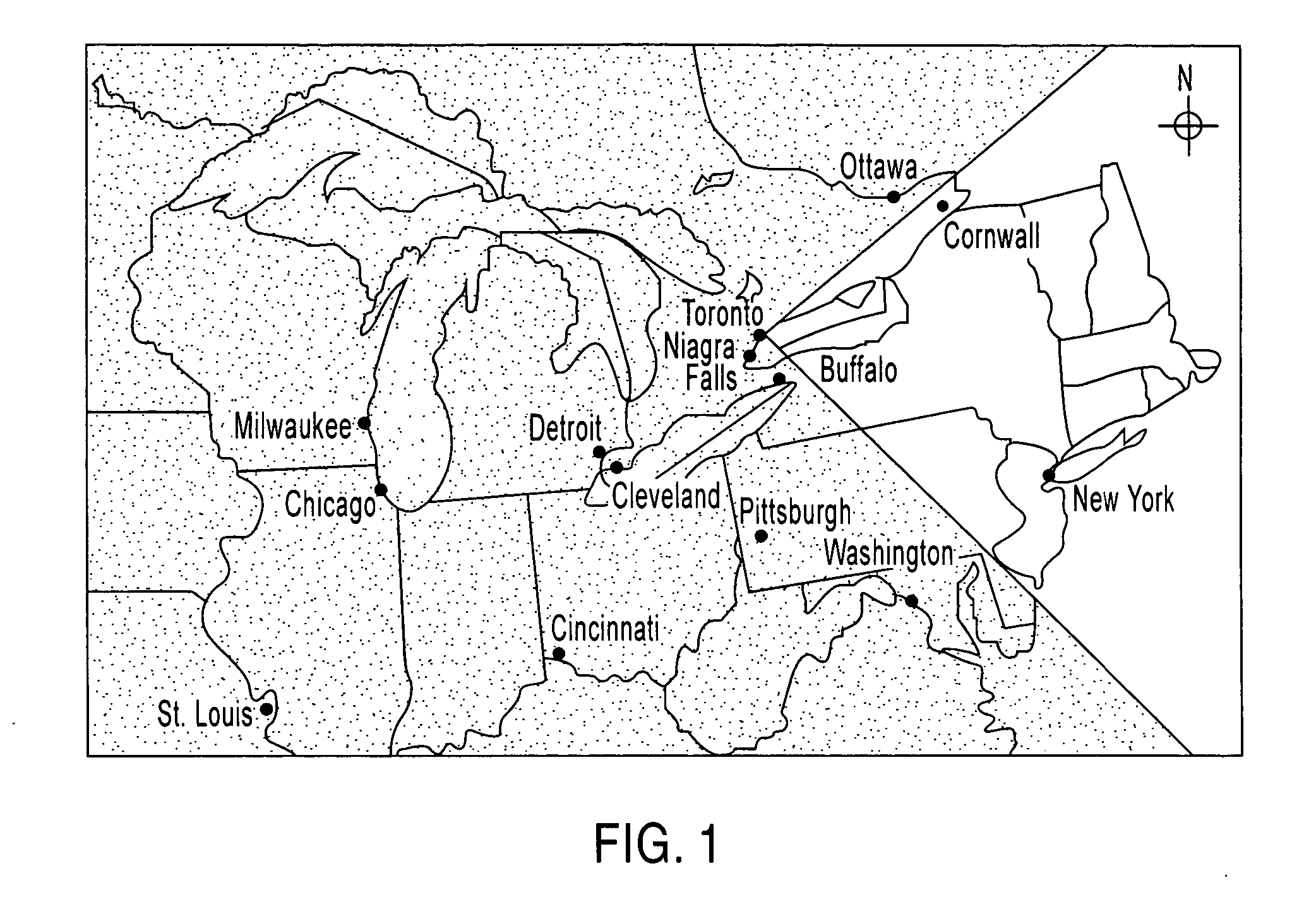

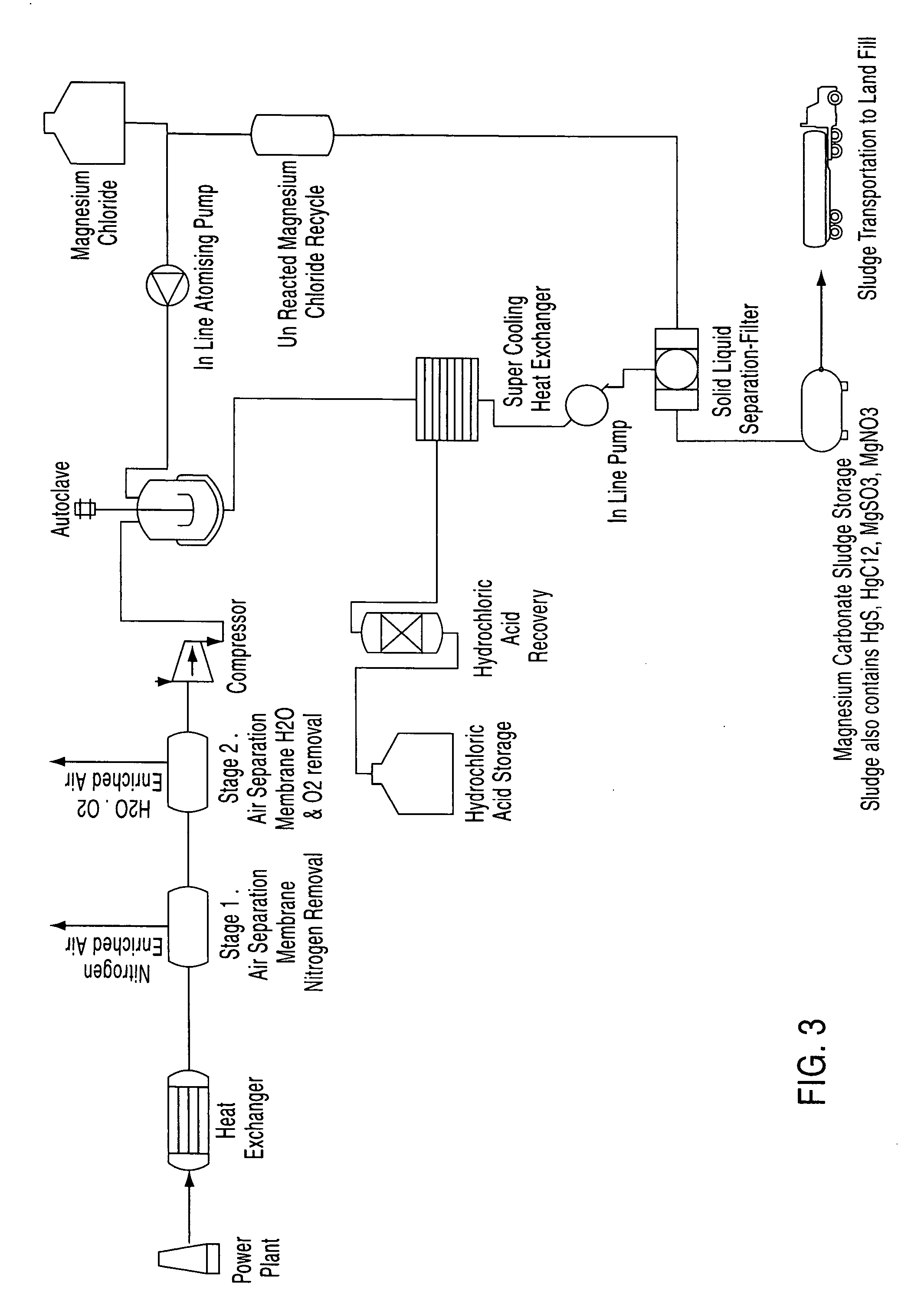

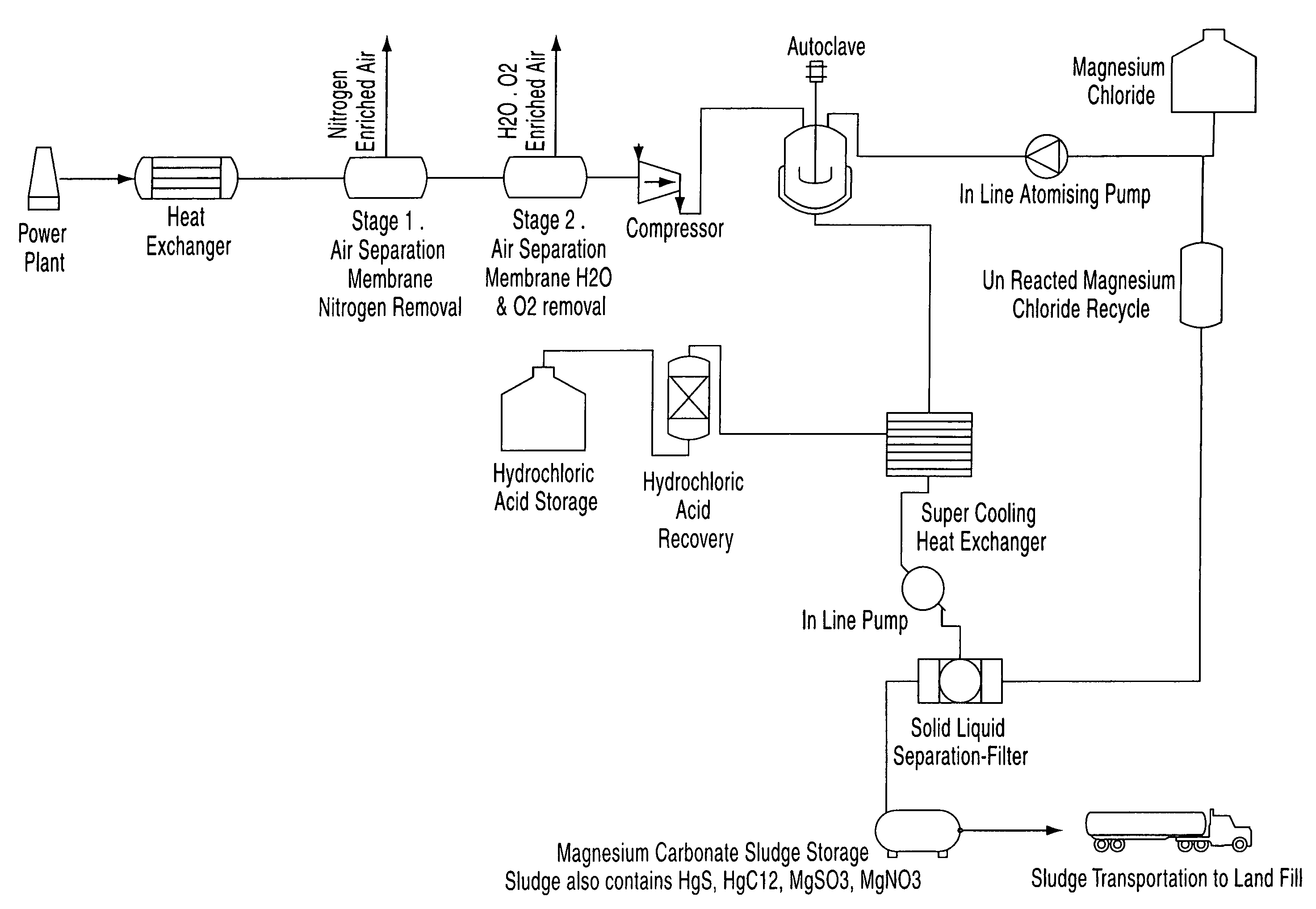

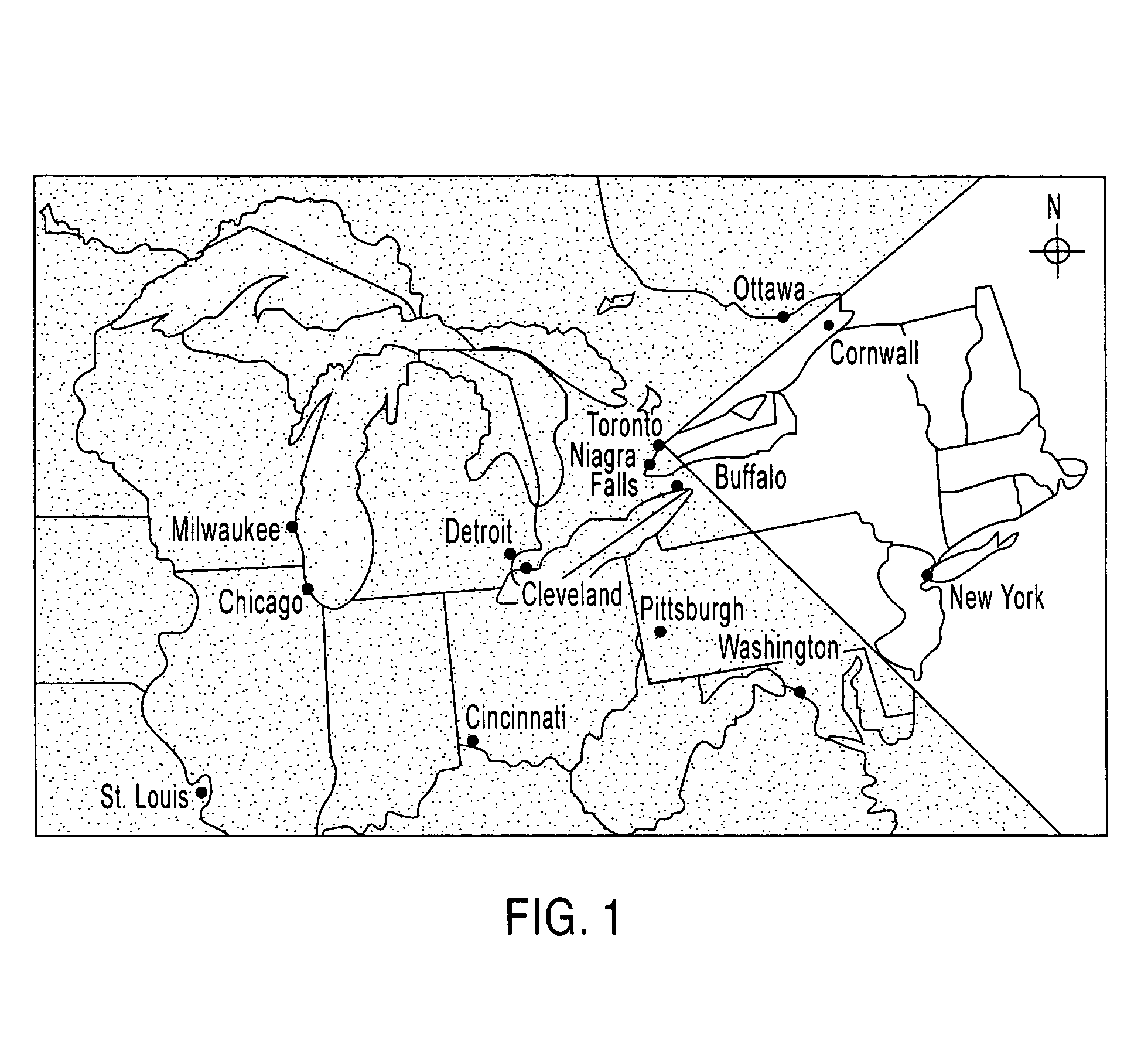

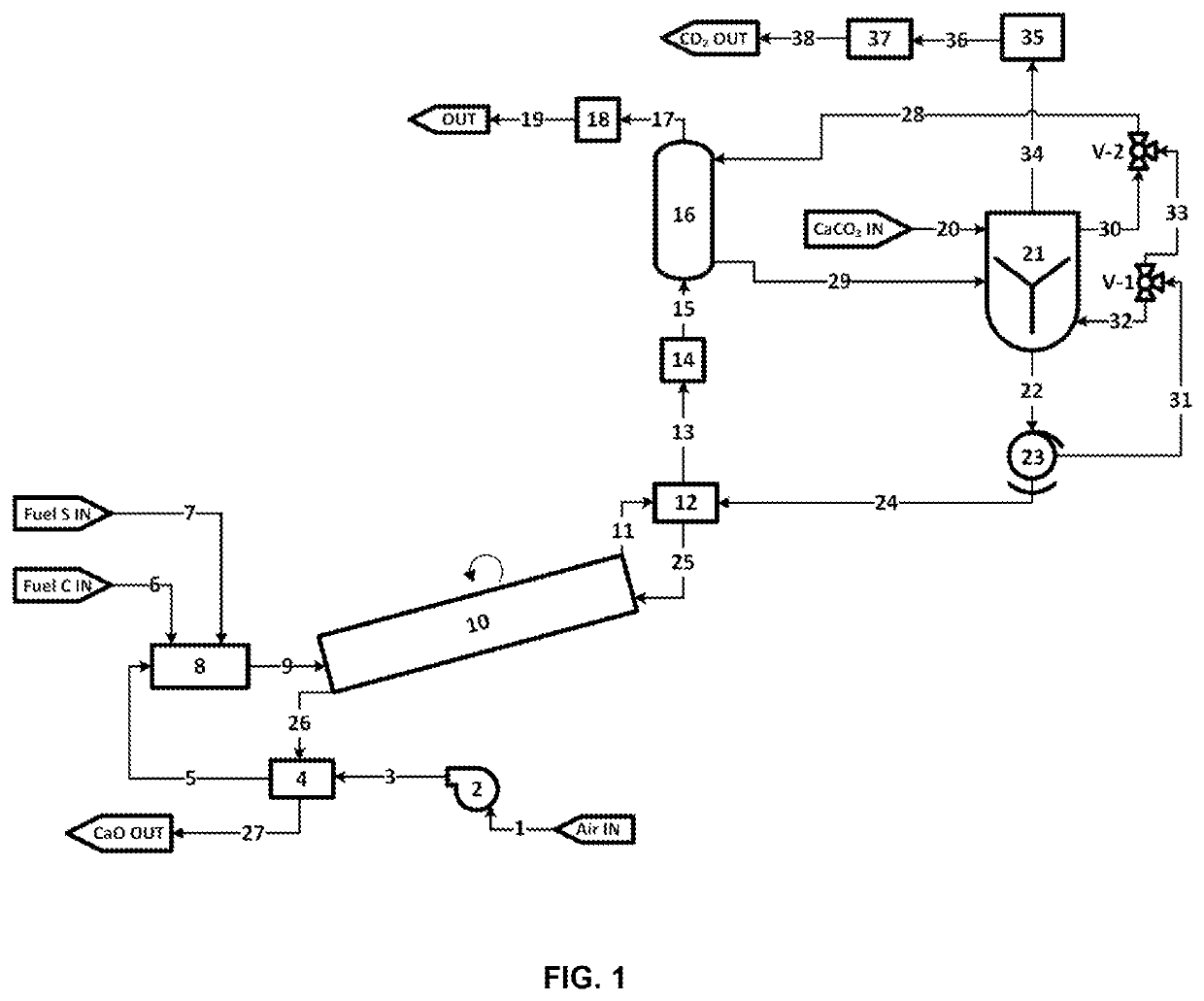

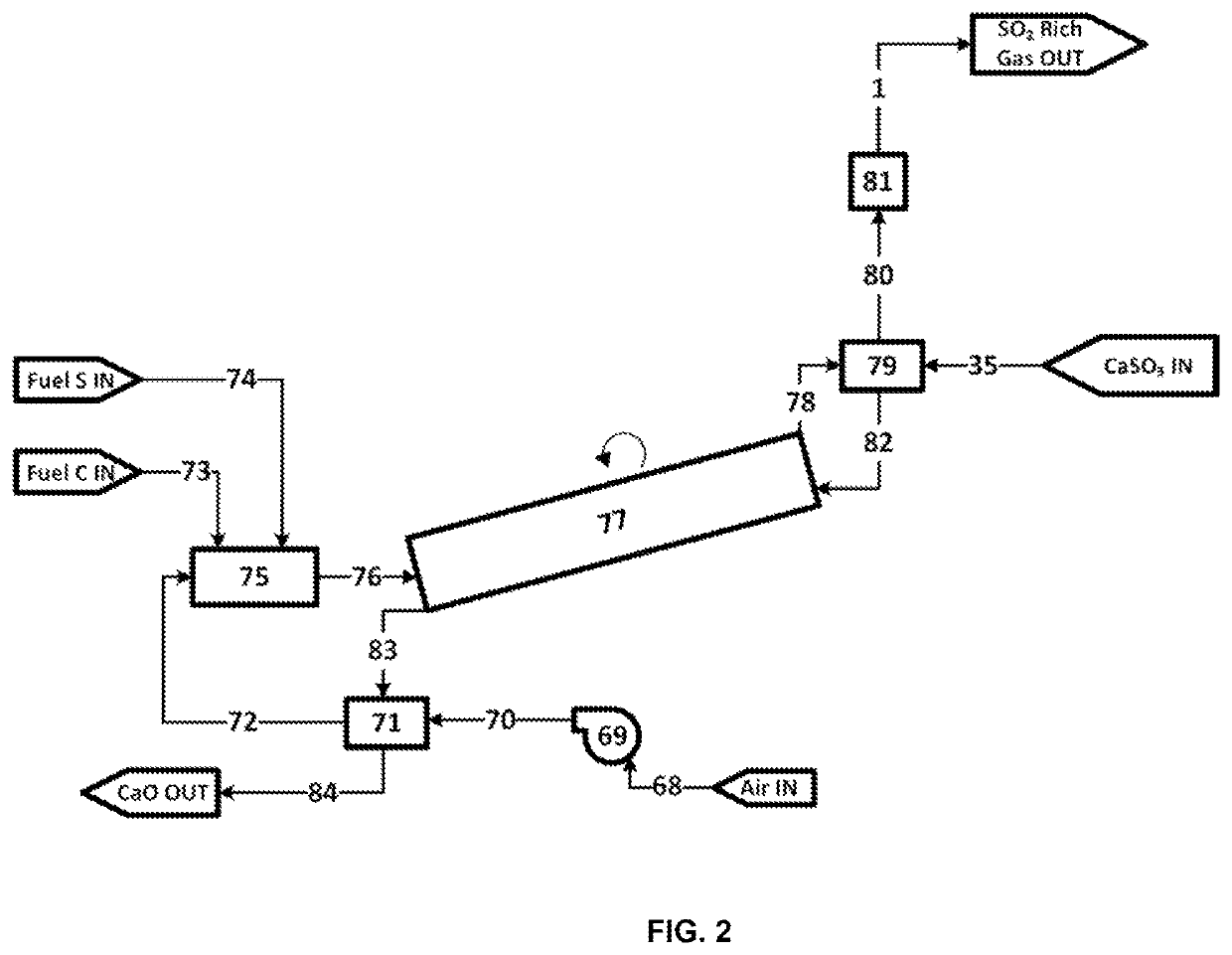

Process for removal of pollutants

A process for the removal of pollutants from a combustion process and, more particularly, a process for removing pollutants such as carbon dioxide, mercury, sulphur dioxide, nitrogen compounds and oxygen compounds from a combustion process. The process includes the removal of pollutants from a combustion process that produces an emission comprising: cooling the emission to a temperature of about 200° C.; removing nitrogen, water and oxygen from the emission to produce a gas containing a concentration of pollutants; contacting the gas with an aqueous magnesium chloride solution, wherein a slurry mixture is formed; and cooling the gas and the slurry mixture, wherein hydrochloric acid vapour and a sludge are formed.

Owner:CLEAN WORLD STRATEGIES CORP

Acidic viscoelastic surfactant based cleaning compositions

ActiveUS20140148372A1Better clingReduce foggingInorganic/elemental detergent compounding agentsCationic surface-active compoundsViscoelasticitySURFACTANT BLEND

Owner:ECOLAB USA INC

Method of making pure salt from frac-water/wastewater

ActiveUS20110104038A1Easy to produceQuality improvementCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesParticulatesWater use

The present invention relates to a method for making pure salt comprises recapturing post-drilling flowback water from hydro-fracturing; removing oil from the flowback water; filtering the flowback water using an ultra filter with a pore size of about 0.1 microns or less to remove solid particulates and large organic molecules, such as benzene, ethylbenzene, toluene, and xylene, from the water; concentrating the flowback water to produce a brine that contains from about 15 wt % to about 40 wt % of salt relative to the total weight of the flowback brine; performing one or more chemical precipitation process using an effective amount of reagents to precipitate out the desired high quality commercial products, such as, barium sulfate, strontium carbonate, calcium carbonate; and crystallizing the chemically treated and concentrated flowback brine to produce greater than 99.5% pure salt products, such as sodium and calcium chloride.

Owner:FRACPURE HLDG

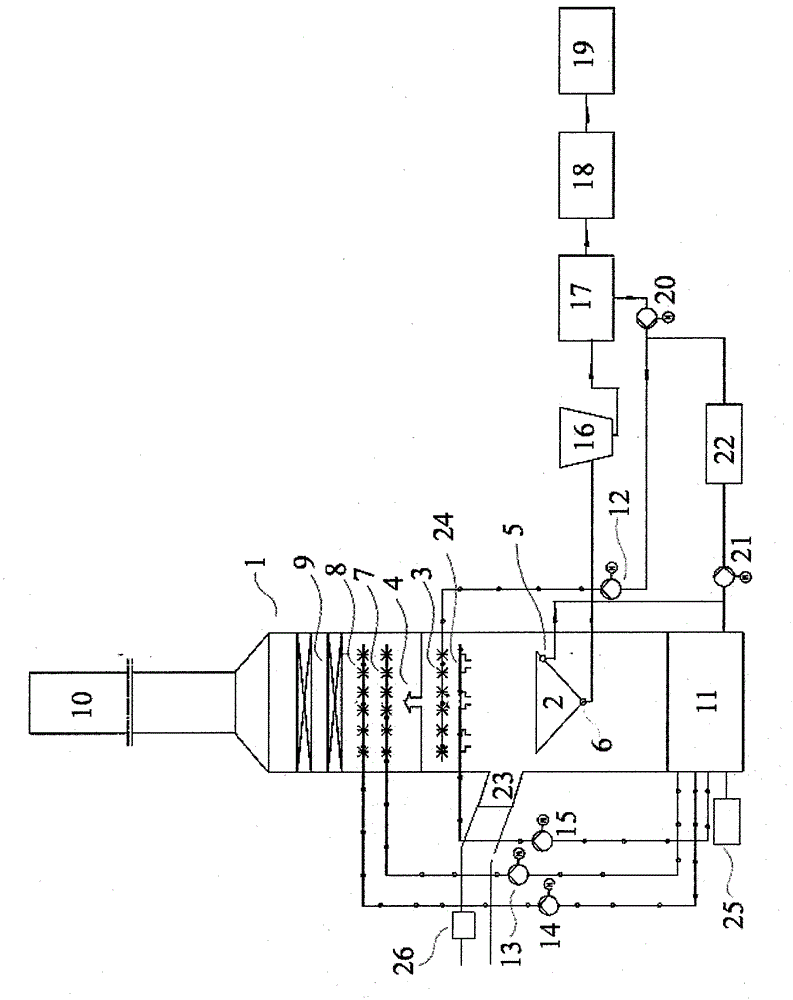

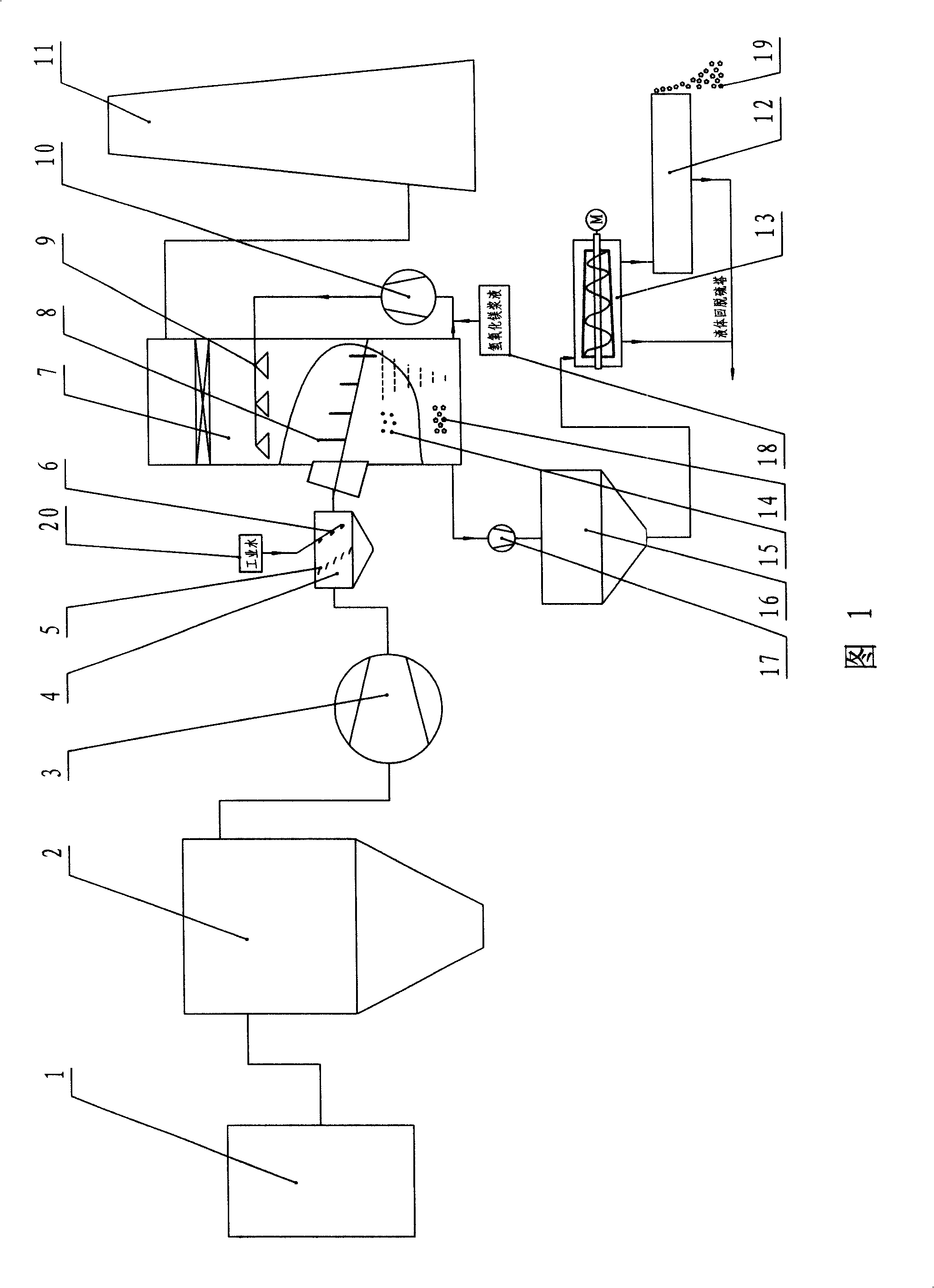

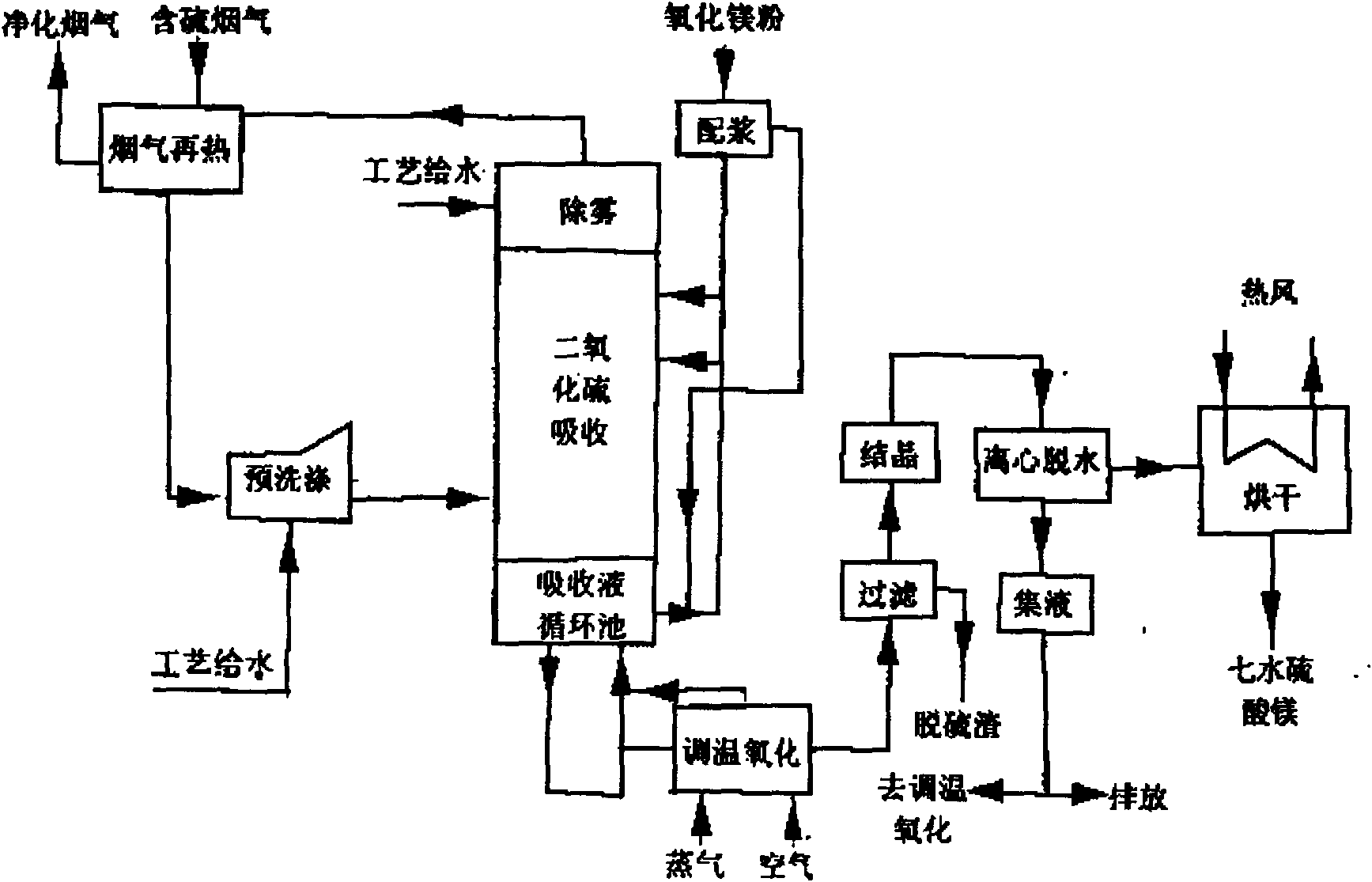

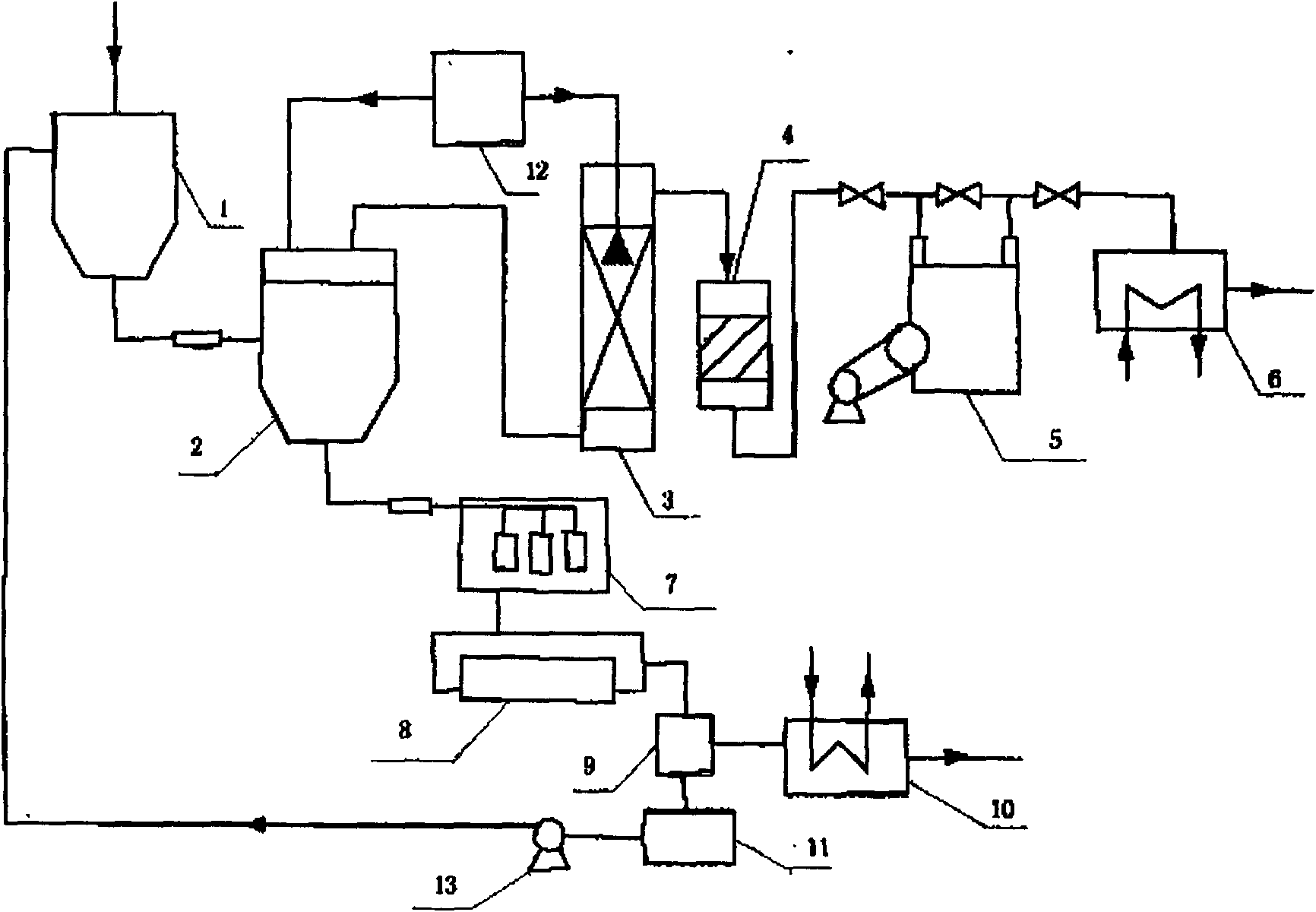

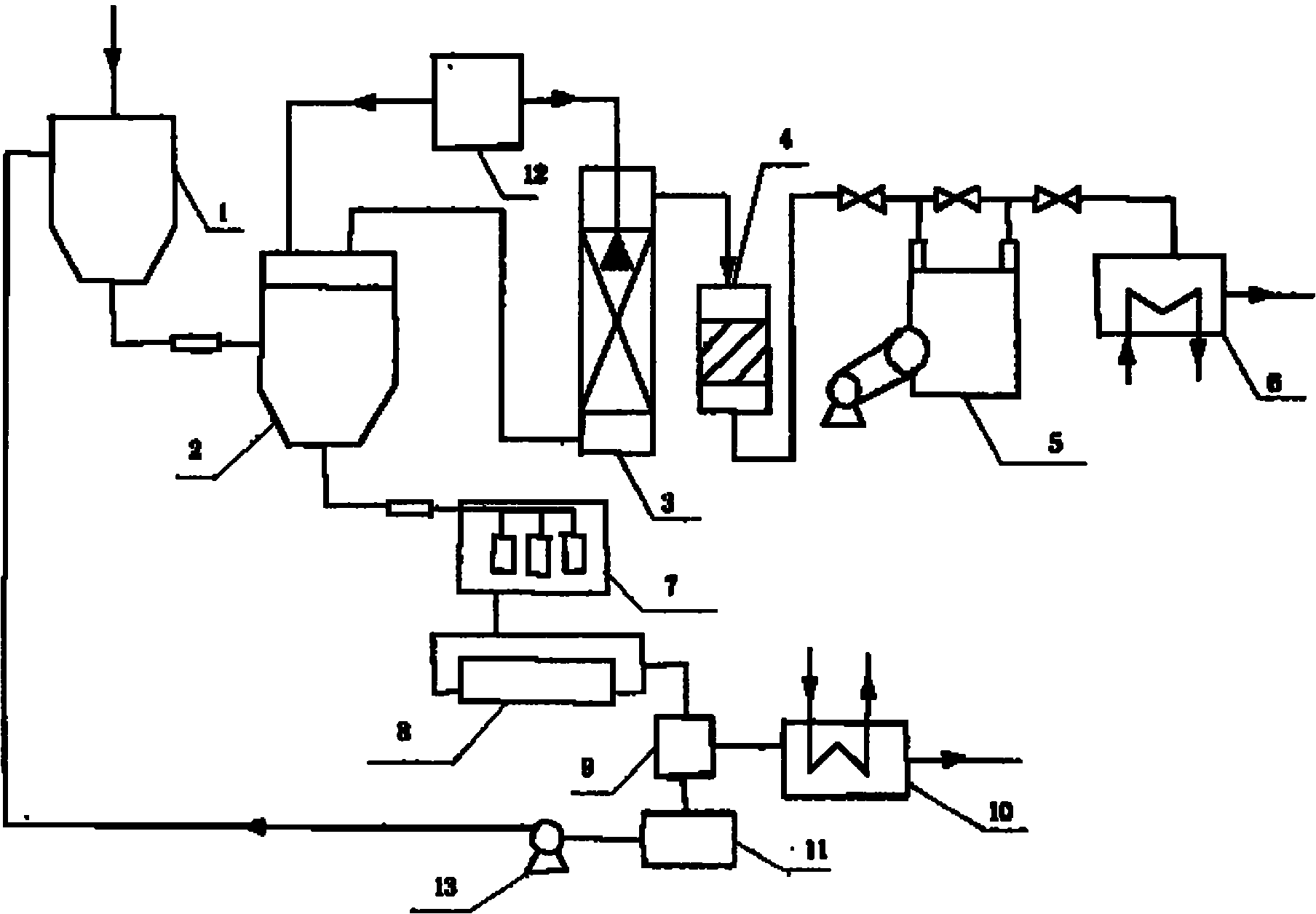

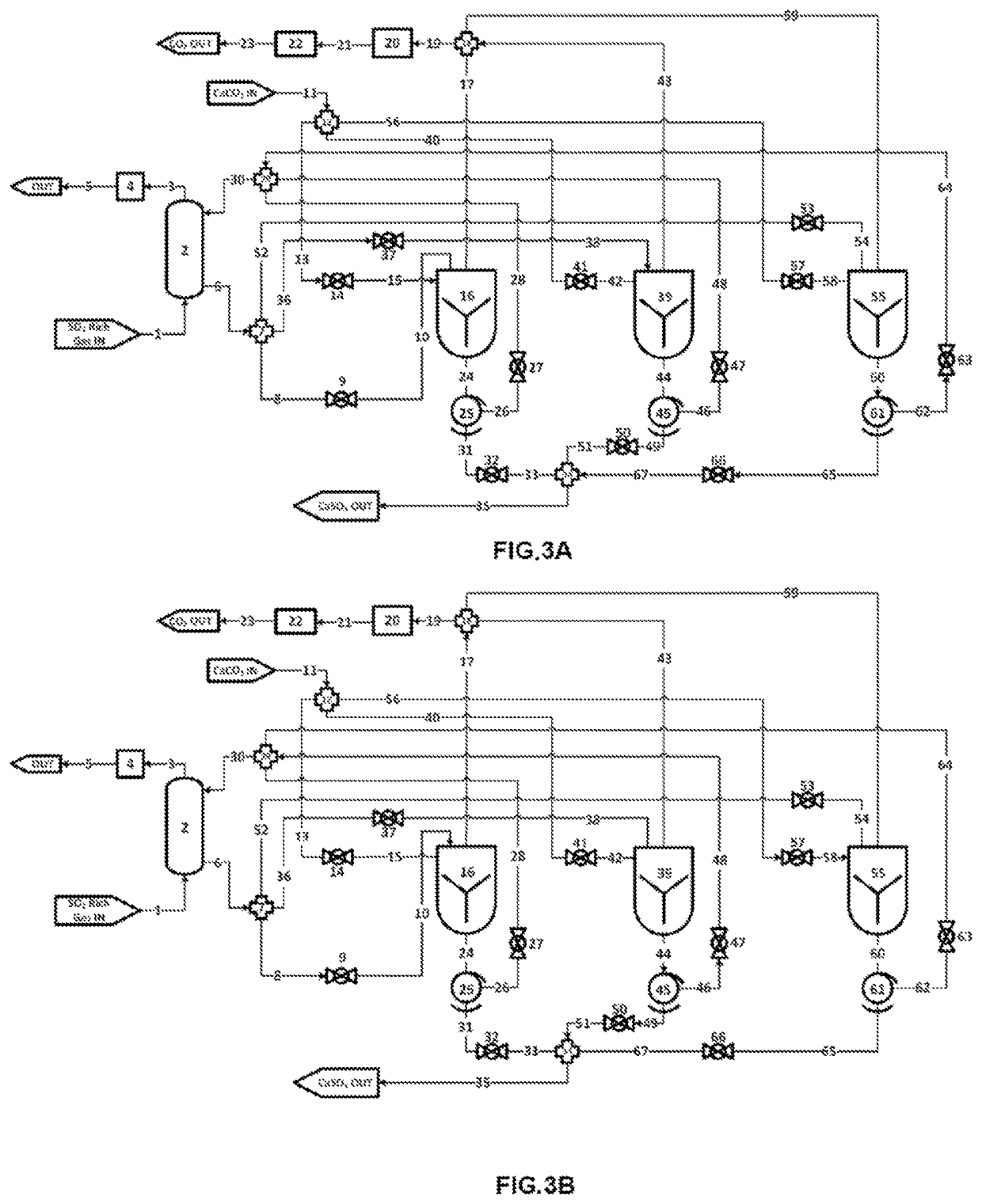

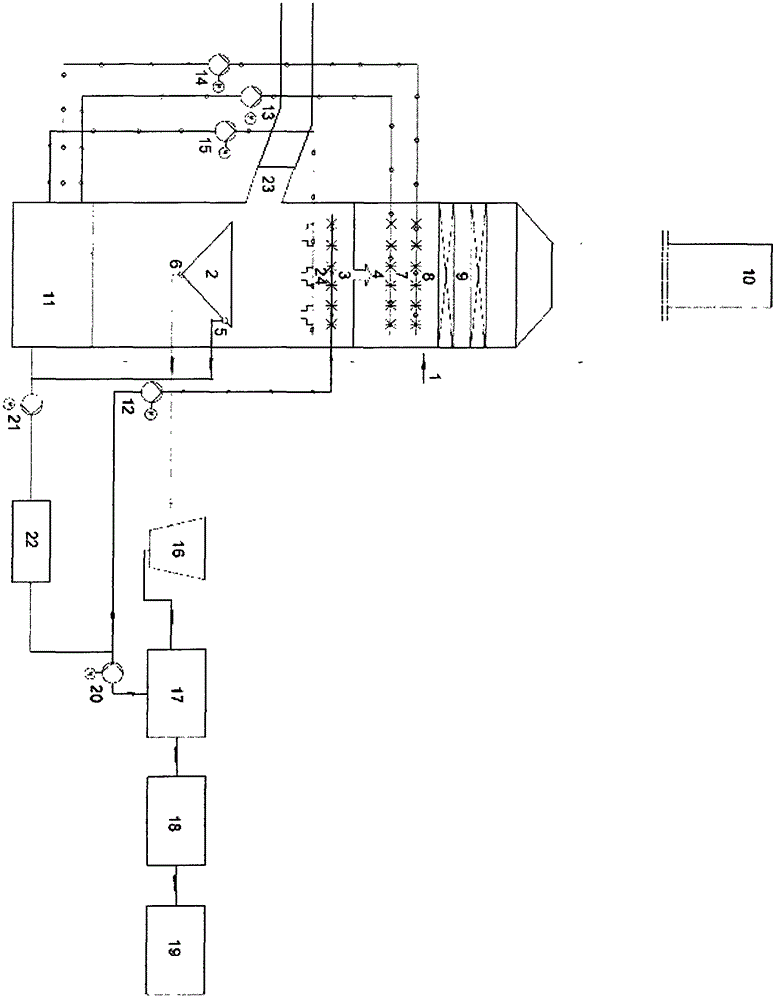

Device and method for producing magnesium sulfate by using flue gas of coal-fired boiler

ActiveCN104477952AReduce power consumptionReduce consumptionGas treatmentMagnesium sulfitesEvaporationSlurry

The invention provides a device and a method for producing magnesium sulfate by using flue gas of a coal-fired boiler, and particularly provides a device and a method for producing the magnesium sulfate by direct crystallization in a magnesium oxide-process waste desulfurization liquid tower by using the flue gas, low in oxygen content, of the coal-fired boiler. The device comprises oxygenation equipment, flue gas desulfurization equipment, slurry circulating equipment, evaporation and concentration equipment, cyclic sedimentation equipment, oxidization equipment, crystallization equipment, centrifugation equipment, drying equipment and the like. By adopting the device and the method disclosed by the invention, the desulfurization efficiency and the quality of a side product magnesium sulfate can be guaranteed under a condition that the wind power consumption and steam consumption of an oxidization fan are greatly reduced, the operating cost of a magnesium sulfate production system is greatly lowered, and the desulfurization operation cost is lowered.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

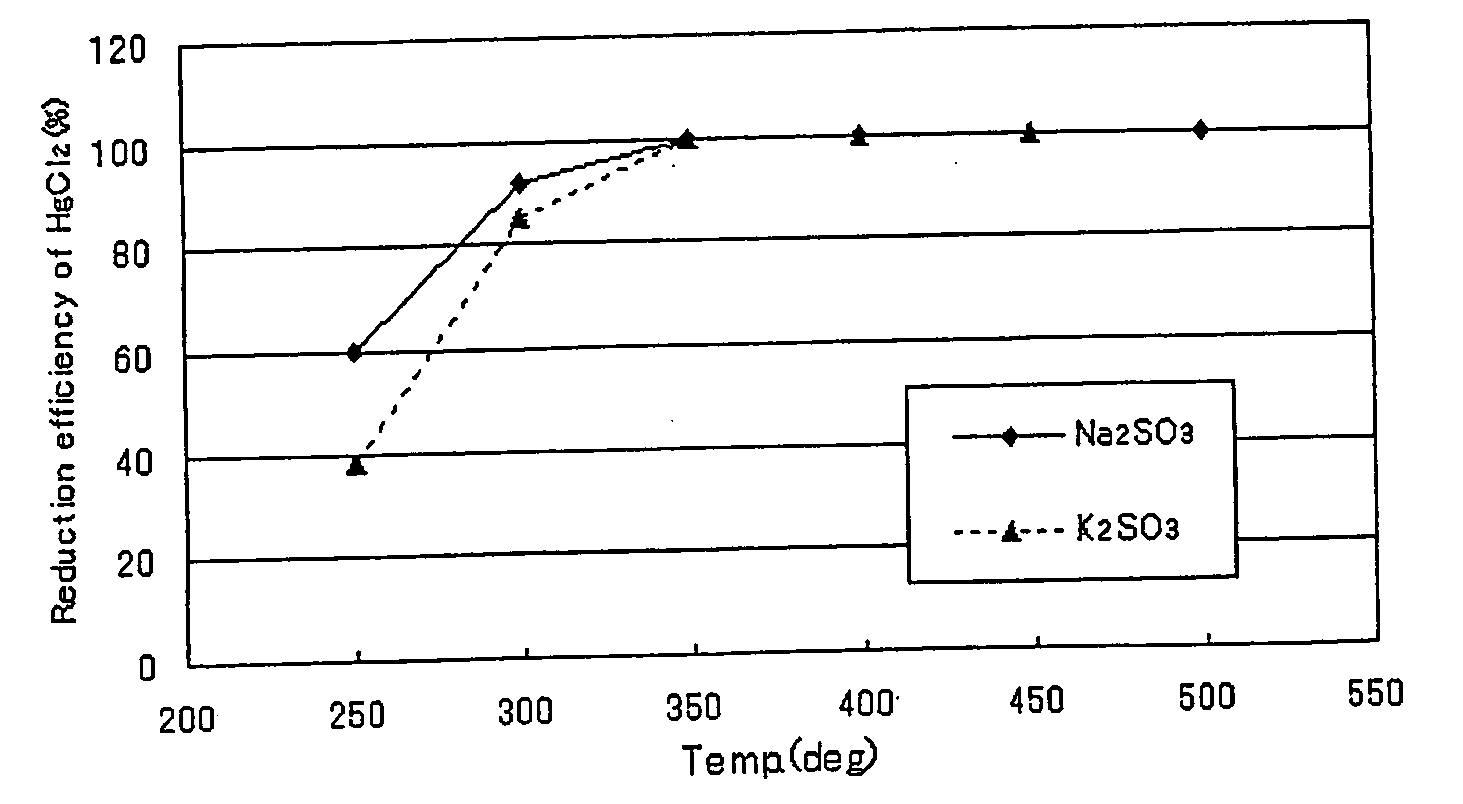

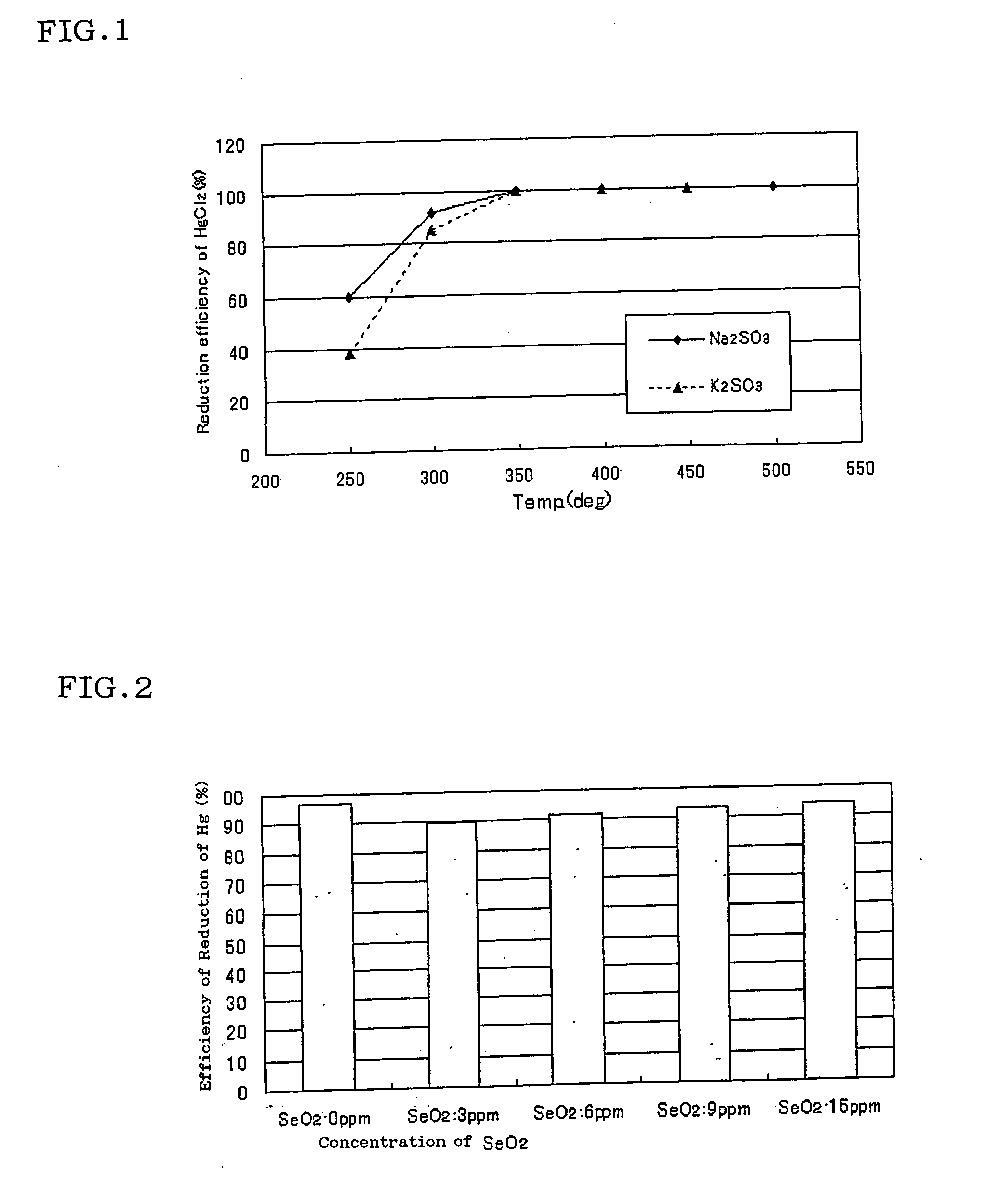

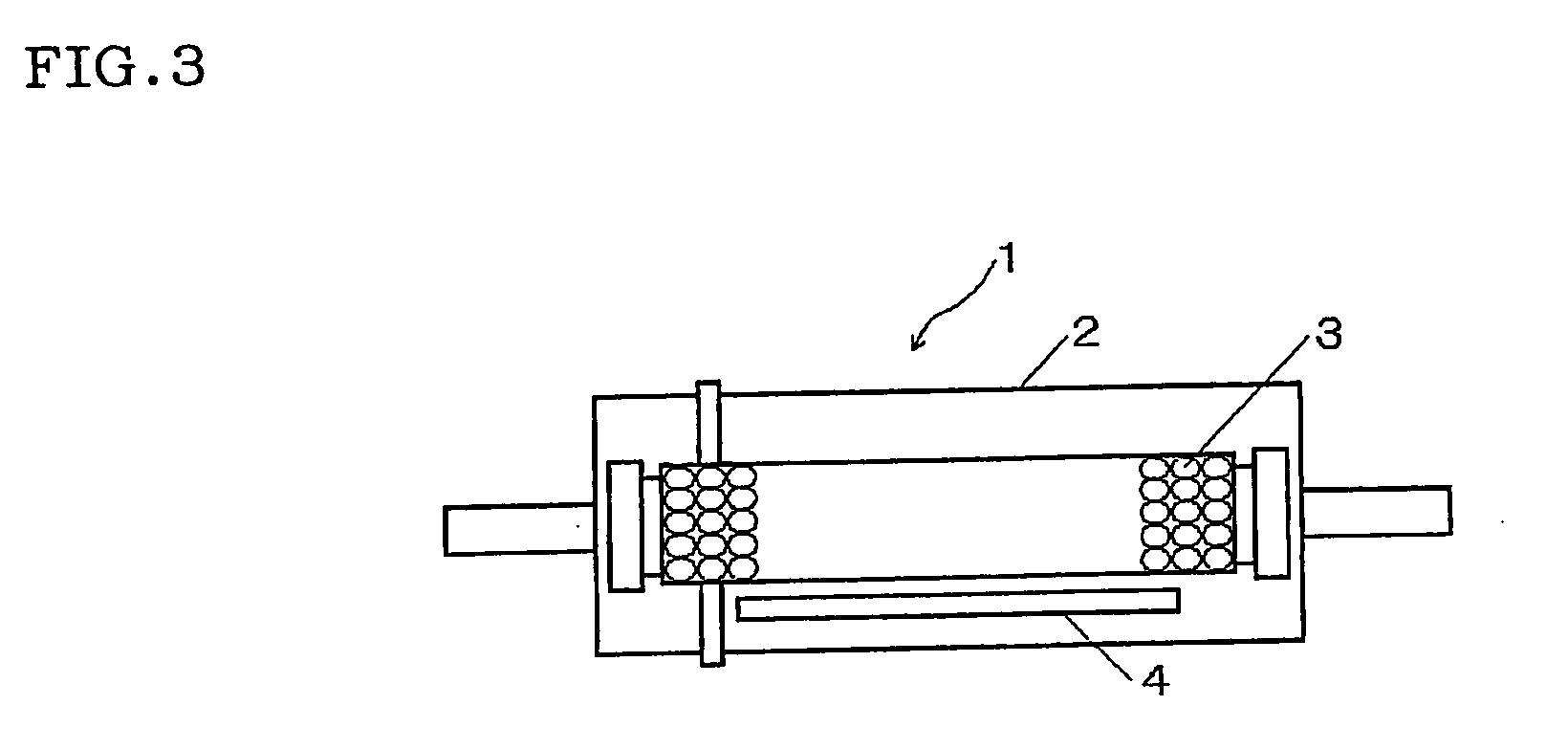

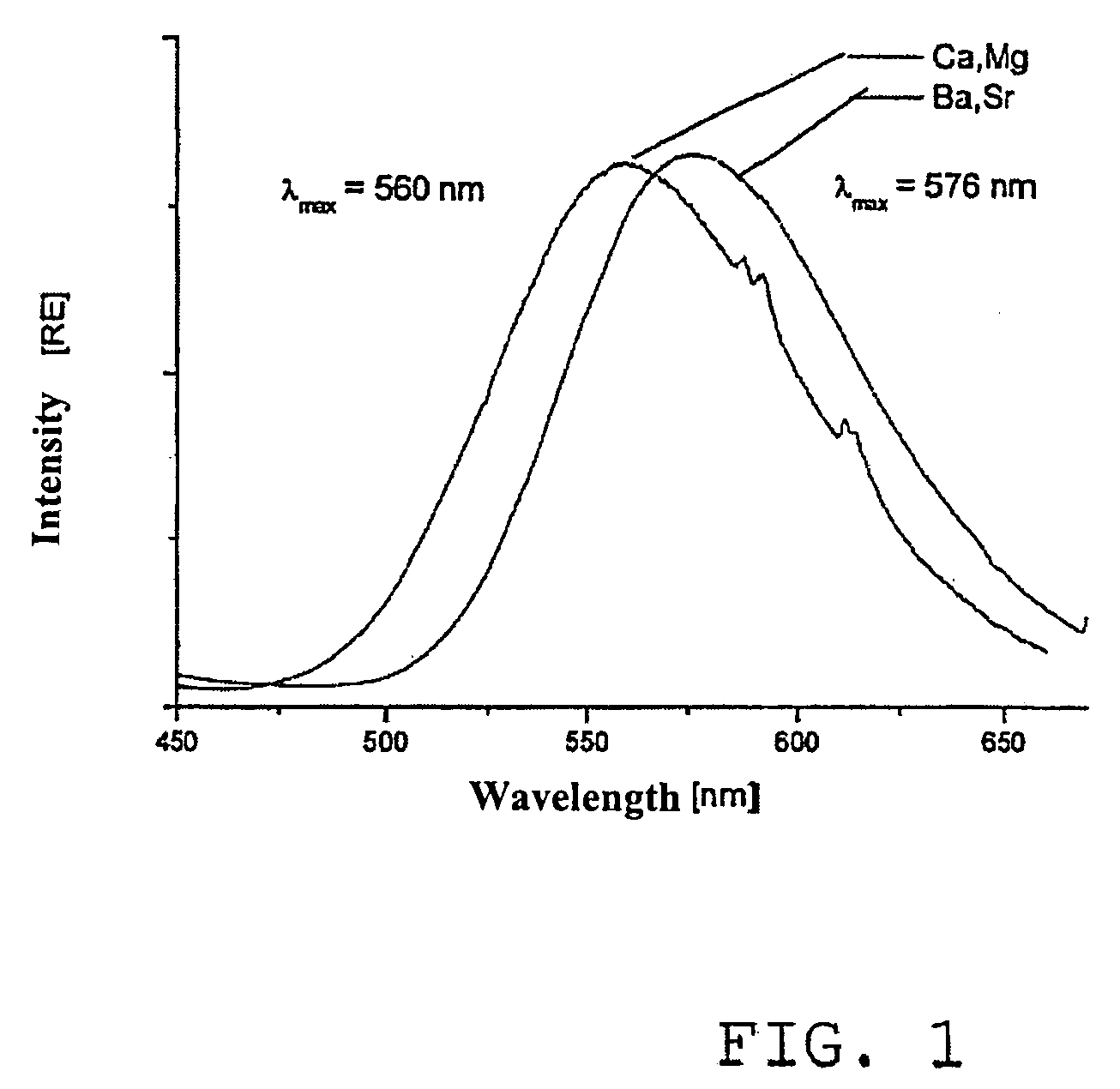

Catalyst for reducing mercury, a mercury conversion unit, and an apparatus for measuring total mercury in combustion exhaust gas by using the same

InactiveUS20070232488A1Reduce functionImprove accuracyCalcium/strontium/barium carbonatesUsing liquid separation agentCombustionPhosphate

The present invention relates to a catalyst for reducing mercury, which comprises a reagent comprising any of the sulfites of potassium, sodium, calcium and magnesium, or any of the phosphates thereof, or a combination of them, as a main reagent of a catalyst component. And the present invention relates to the catalyst for reducing mercury, wherein the catalyst component is mixed with a different salt as an agent for inhibiting crystallization of the catalyst component.

Owner:HORIBA LTD

Technique for preparing magnesium sulfite during magnesium method desulfurization process

InactiveCN101254932AImprove solubilityReduce solubilityDispersed particle separationMagnesium sulfitesMagnesium sulfiteImpurity

The invention discloses a preparation method of magnesium sulfite during the desulphurization with magnesium oxide, which is capable of reducing the system water consumption and improving the yield of the magnesium sulfite. The preparation method includes: (1) removing impurities: guiding fume containing sulfur dioxide into a pretreatment device, removing partial fine powder dust, the hydrogen chloride and the hydrogen fluoride from the fume in the pretreatment device with atomized water sprayed from a spraying device, and loading the fume to a desulfurizing tower; (2) desulfurizing: allowing thje sulfur dioxide in the fume and the magnesium hydroxide slurry to react in the desulfurizing tower so as to remove the sulfur dioxide from the fume and further arranging the oxidation inhibitor simple substance or the sodium thiosulfate in order to prevent oxidation of the generated magnesium sulfite by the oxygen in the fume to obtain magnesium sulfate; and (3) separating: flocculating and settling the desulfurized slurry to obtain sediment, and performing the solid-liquid separation to obtain dried magnesium sulfite byproducts.

Owner:JIANGSU NEW ENVIRONMENTAL CORP

Sorbents for removal of mercury from flue gas cross reference to related applications

InactiveUS7771700B2Solid waste managementUsing liquid separation agentParticulatesAlkaline earth metal

Owner:CHEM PROD CORP

Reduction in mineral salt deposition

InactiveUS6881231B2Energy was cheapEffective controlCalcium/strontium/barium carbonatesMagnesium chloridesAqueous solutionSolid surface

A composition for reducing deposition of a mineral salt from an aqueous supersaturated solution onto a solid surface in contact with the aqueous supersaturated solution which composition comprises a dispersion of either (i) seed crystals of the mineral salt in an aqueous solution of the mineral salt or (ii) seed crystals of a salt isomorphous with the mineral salt in an aqueous solution of the isomorphous salt wherein the dispersed seed crystals are of Mean particle size of less than 2.5 microns.

Owner:ASYMPTOTE

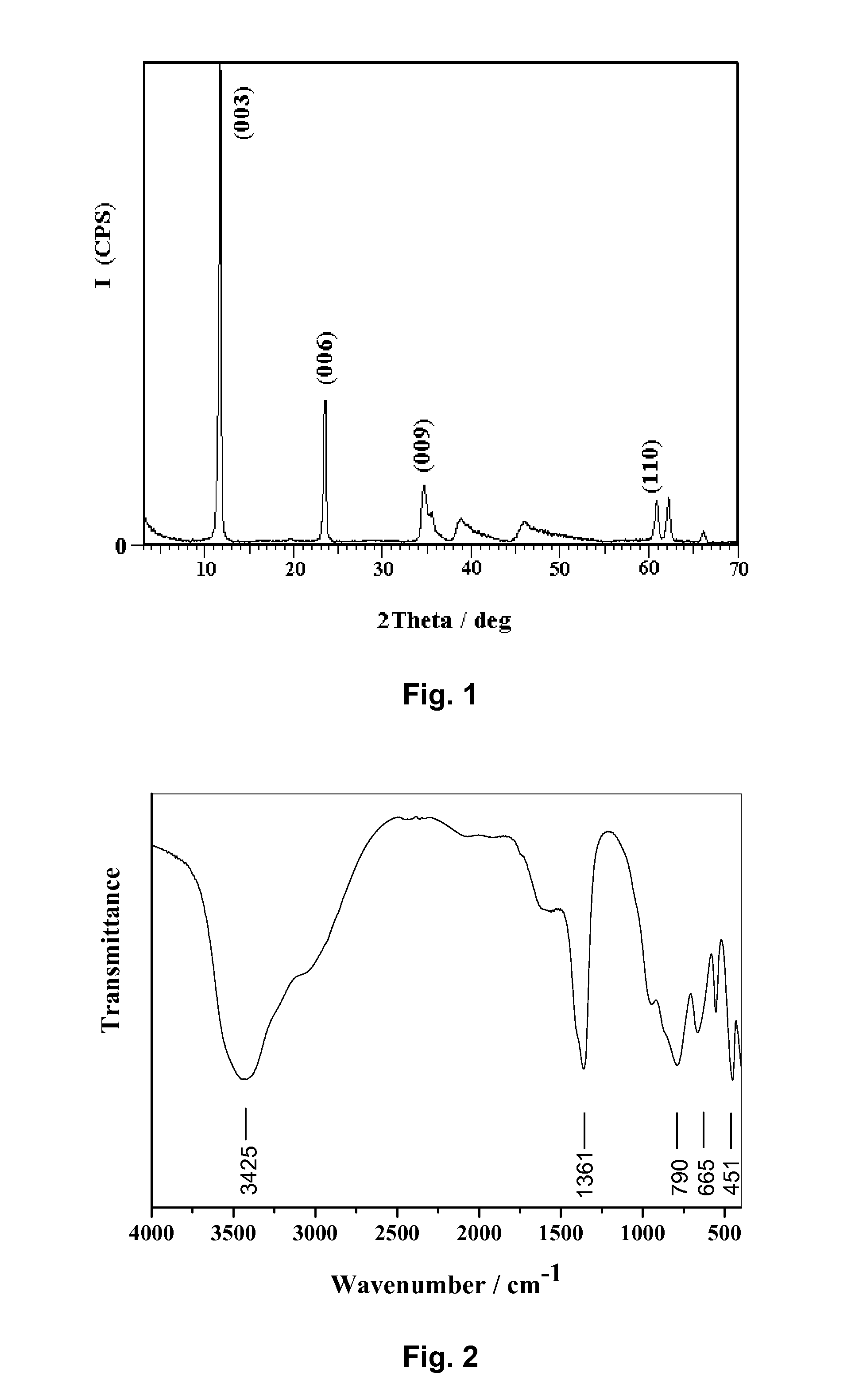

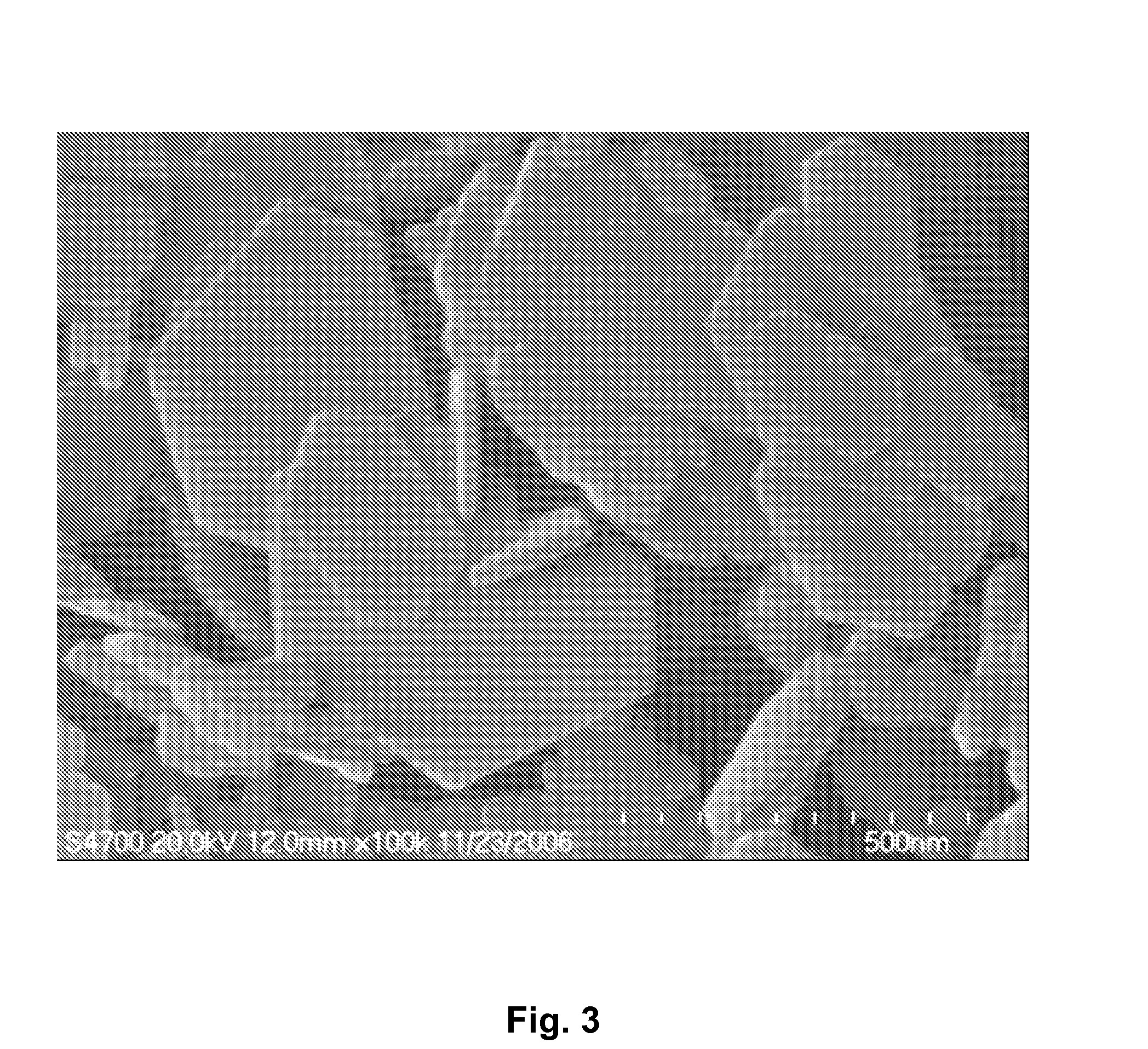

Clean method for preparing layered double hydroxides

ActiveUS8088349B2Prevent materialAvoid prolonged useLithium compoundsManganese oxides/hydroxidesCleaning methodsLayered double hydroxides

Disclosed is a clean method for preparing layered double hydroxides (LDHs), in which hydroxides of different metals are used as starting materials for production of LDHs by atom-economical reactions. The atom efficiency of the reaction is 100% in each case because all the atoms of the reactants are converted into the target product since only M2+(OH)2, M3+(OH)3, and CO2 or HnAn− are used, without any NaOH or other materials. Since there is no by-product, filtration or washing process is unnecessary. The consequent reduction in water consumption is also beneficial to the environment.

Owner:BEIJING UNIV OF CHEM TECH

Recovery method of magnesium oxide flue gas desulfurization product

InactiveCN102078750ASmall processing rateReduce circulationDispersed particle separationMagnesium sulfitesRecovery methodResource utilization

The invention discloses a recovery method of a magnesium oxide flue gas desulfurization product, belonging to the technical field of resource utilization of flue gas desulfurization products and comprising the following steps of: inhibiting the oxidation of an absorption liquid during circulation desulfurization, facilitating the crystallization and the precipitation of MgSO3 (magnesium sulfite), pumping out concentrated slurry from the bottom of a circulation pool by using a centrifugal pump when the concentrated slurry is reached, filter-pressing the concentrated slurry into a solid through a plate frame, transporting the solid to a professional desulfurization product recovery plant, and reacting concentrated sulfuric acid with the MgSO3 to generate an MgSO4 (magnesium sulfate) serous liquid and an SO2 (sulfur dioxide) gas; and collecting the SO2 through a tiny negative pressure, drying, cooling, liquefying and canning the SO2, filtering, crystallizing and centrifugally dewatering the serous liquid so that the separation of solid-phase and liquid phase impurities is realized, and stoving to form an industrial product. By virtue of the method, the industrial production of MgSO4.7H2O and liquid-state SO2 is realized, a set of green chemical process is created with the flue gas desulfurization, the desulfurization, the recovery efficiency and the economic benefit are improved, and the technical and economical properties of the magnesium oxide flue gas desulfurization are comprehensively enhanced.

Owner:TSINGHUA UNIV

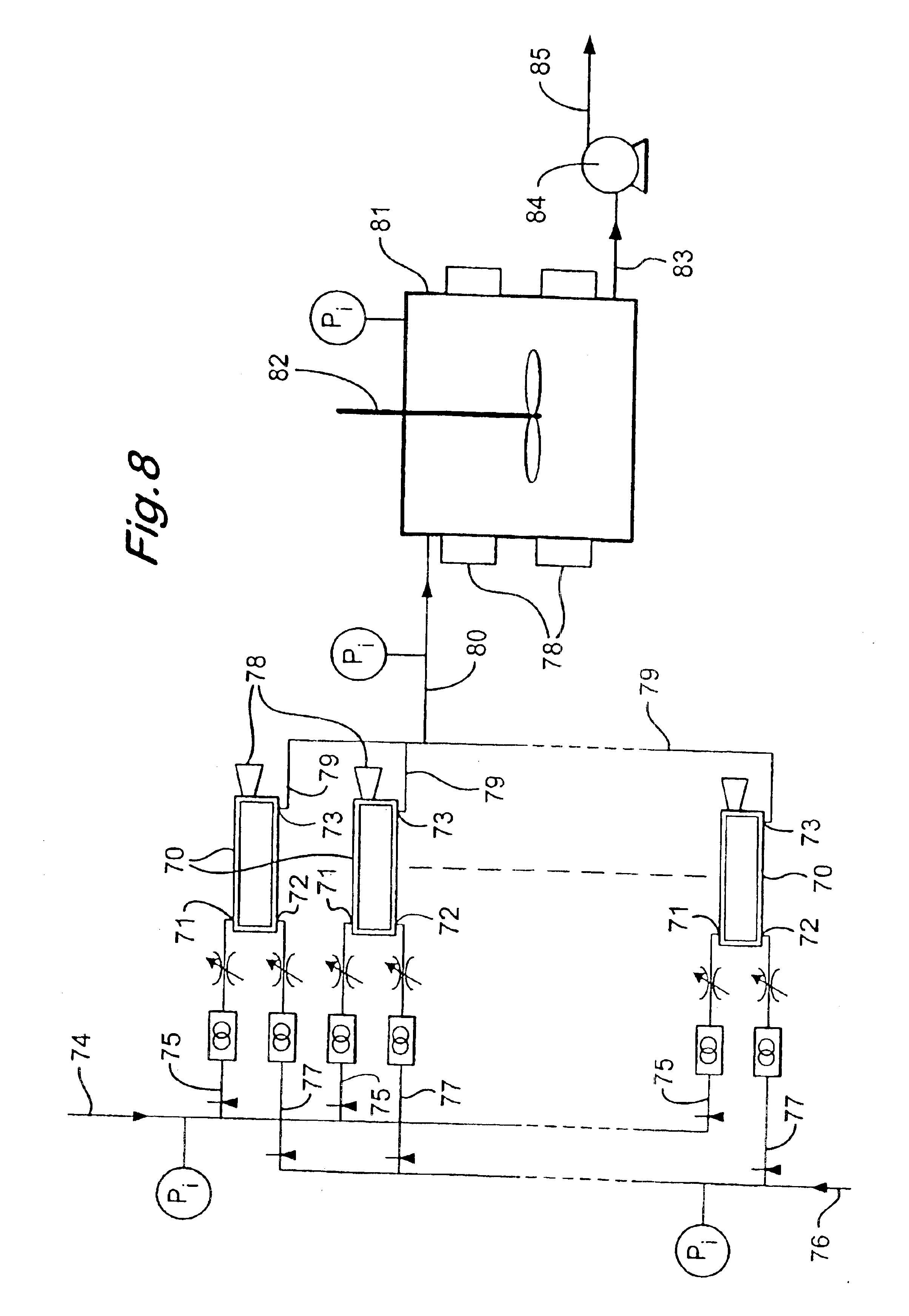

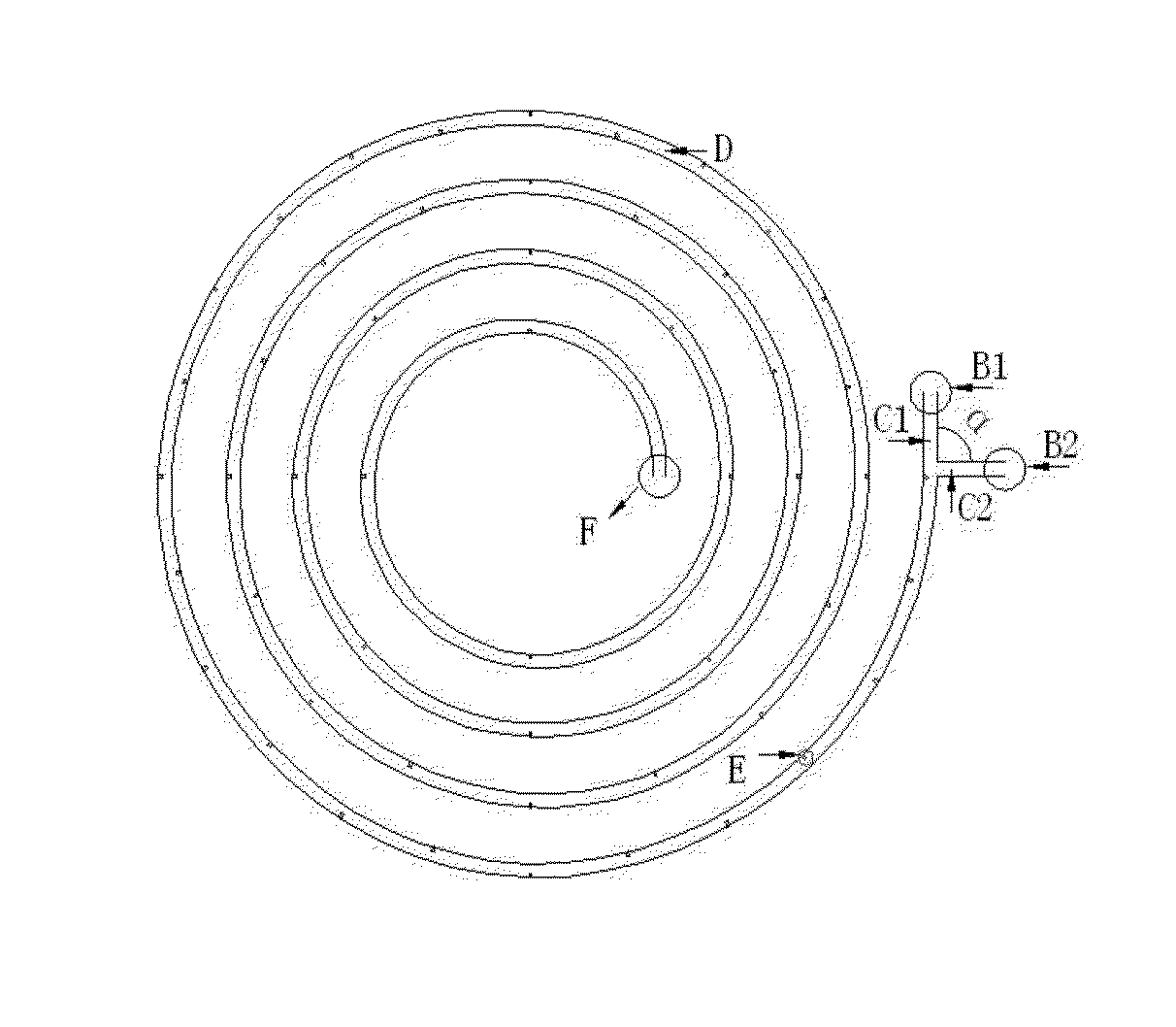

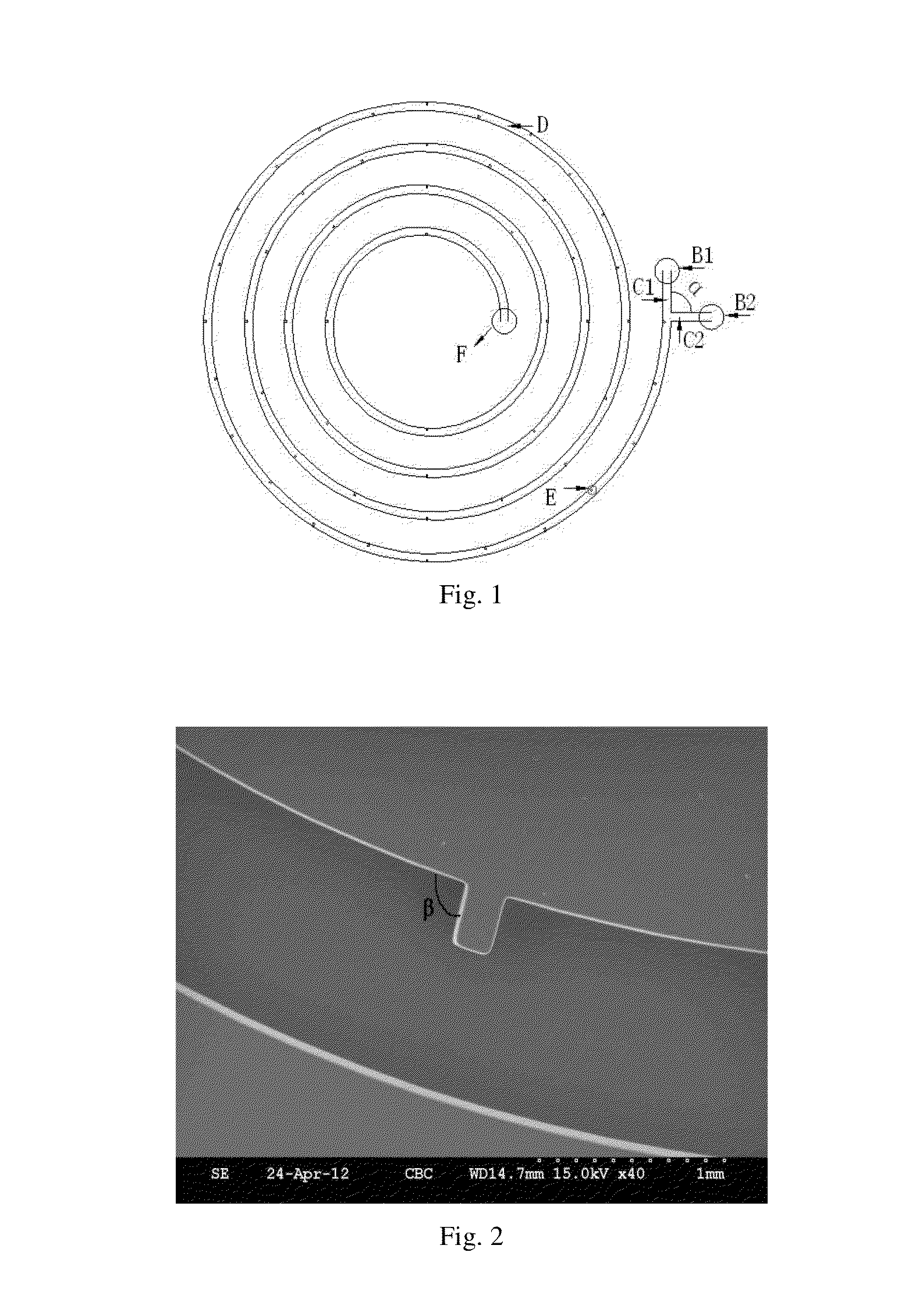

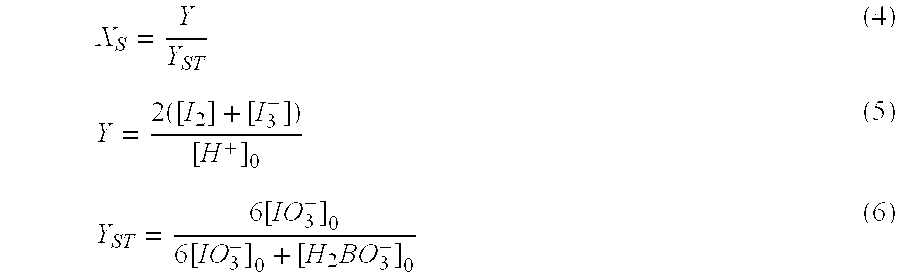

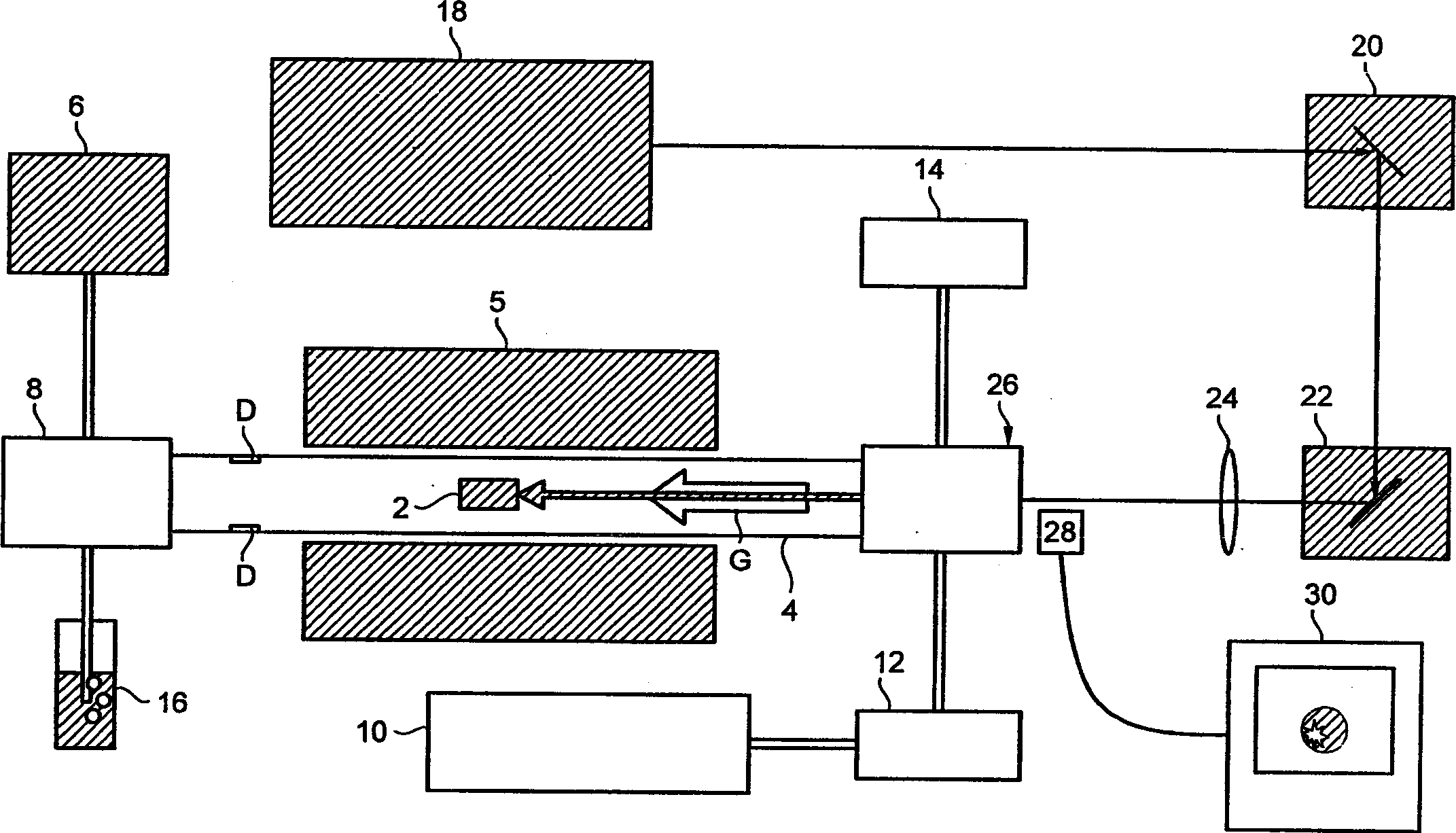

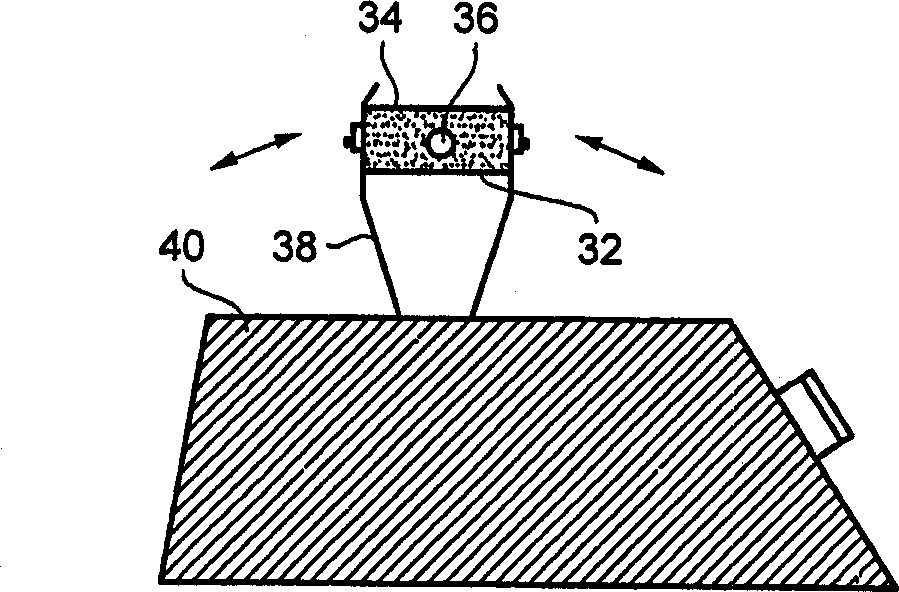

Passive spiral micromixer and its applications

A micro-mixer and use thereof for synthesis of barium sulfate particles is disclosed. The micro-mixer includes feeding tubes, reservoirs, a mixing channel, a buffer reservoir and a sampling tube. The mixing channel is made of hydrophobic materials and processed into a spiral structure, in which baffles are set in interval arrangement at both sides of the channel wall. The types of the baffles include leaning-forward baffles, vertical baffles and leaning-backward baffles. Setting the baffles helps produce local secondary flow in the mixer, which enhances fluids mixing process. The micro-mixer is suitable to rapid reactions or precipitation processes, whose reaction time is much less than mixing time, and has broad application prospects in many fields involving mixing reaction such as pharmaceutical and chemistry industry.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Nanotube-based high energy material and method

InactiveCN1347389AImprove adhesionMaterial nanotechnologyElectrode manufacturing processesLithiumHigh energy

A carbon-based material containing an allotrope of carbon, such as single-walled carbon nanotubes, is capable of accepting and intercalated alkali metal. The material exhibits a reversible capacity ranging from approximately 650 mAh / g-1,000 mAh / g. The high capacity of the material makes it attractive for a number of applications, such as a battery electrode material. A method of producing a single-walled carbon nanotube material includes purifying an as-recovered nanotube material, and depositing the purified material onto a conductive substrate. The coated substrate is incorporated into an electrochemical cell, an its ability to accept intercalated materials, such as an alkali metal (e.g.-lithium) is measured.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

Flaky particle and cosmetic

InactiveUS20100098780A1Improve smoothnessHigh ability to give skin natural toneCosmetic preparationsBiocideTransmittanceSericite

The present invention has an object to provide a flaky particulate material giving skin an excellent smoothness, which is free from whitening problem upon use thereof owing to its high transparency. The present invention also has another object to provide a cosmetic composition containing the flaky particulate material. The present invention relates to flaky particulate material, which has an average coefficient of friction is not more than 0.50, and a total light transmittance is not less than 85%. A particle in the flaky particulate material comprises a substrate particle made of one material selected from the group consisting of mica, a synthetic mica, sericite, talc, barium sulfate and aluminum oxide. The present invention provides a flaky particulate material that gives skin excellent smoothness, a natural tone, and a matt appearance. The flaky particulate material of the present invention gives a cosmetic composition which provides great comfort of use, and an excellent appearance.

Owner:SAKAI CHEM IND CO LTD

Process for removal of pollutants

A process for the removal of pollutants from a combustion process and, more particularly, a process for removing pollutants such as carbon dioxide, mercury, sulphur dioxide, nitrogen compounds and oxygen compounds from a combustion process. The process includes the removal of pollutants from a combustion process that produces an emission comprising: cooling the emission to a temperature of about 200° C.; removing nitrogen, water and oxygen from the emission to produce a gas containing a concentration of pollutants; contacting the gas with an aqueous magnesium chloride solution, wherein a slurry mixture is formed; and cooling the gas and the slurry mixture, wherein hydrochloric acid vapour and a sludge are formed.

Owner:CLEAN WORLD STRATEGIES CORP

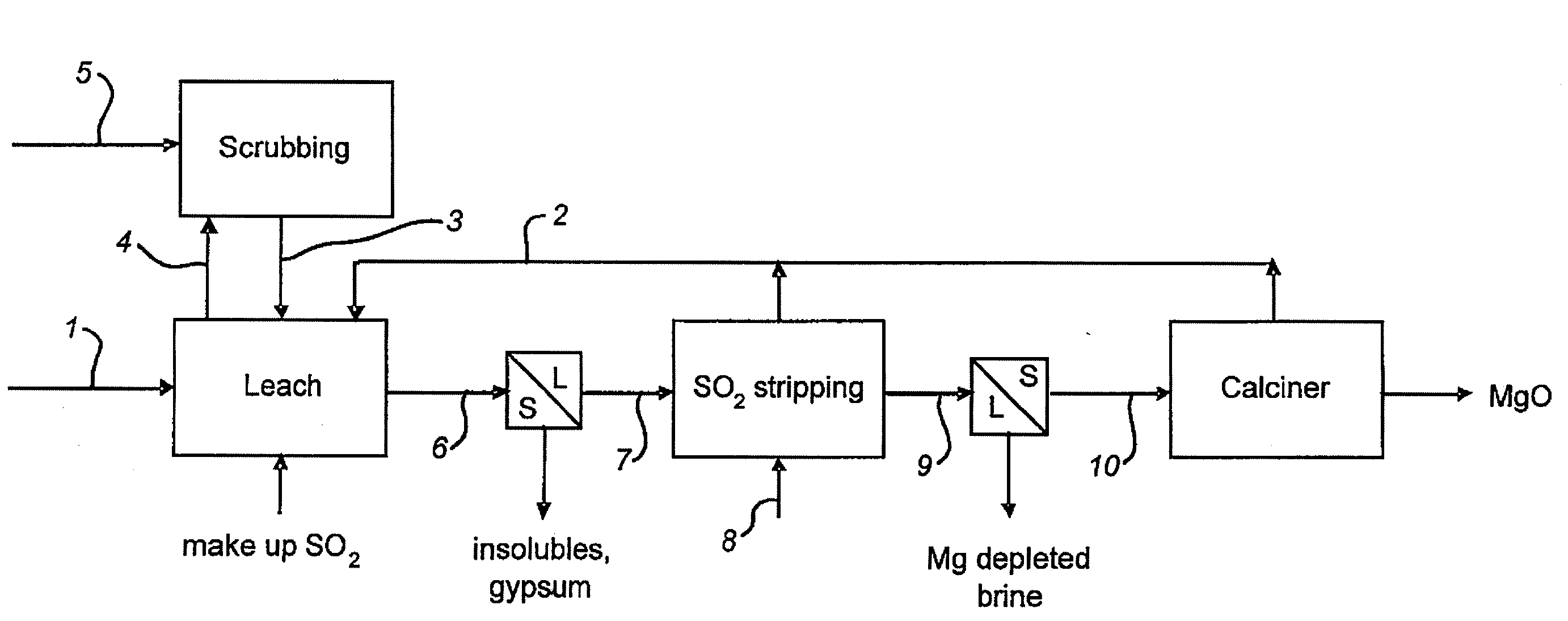

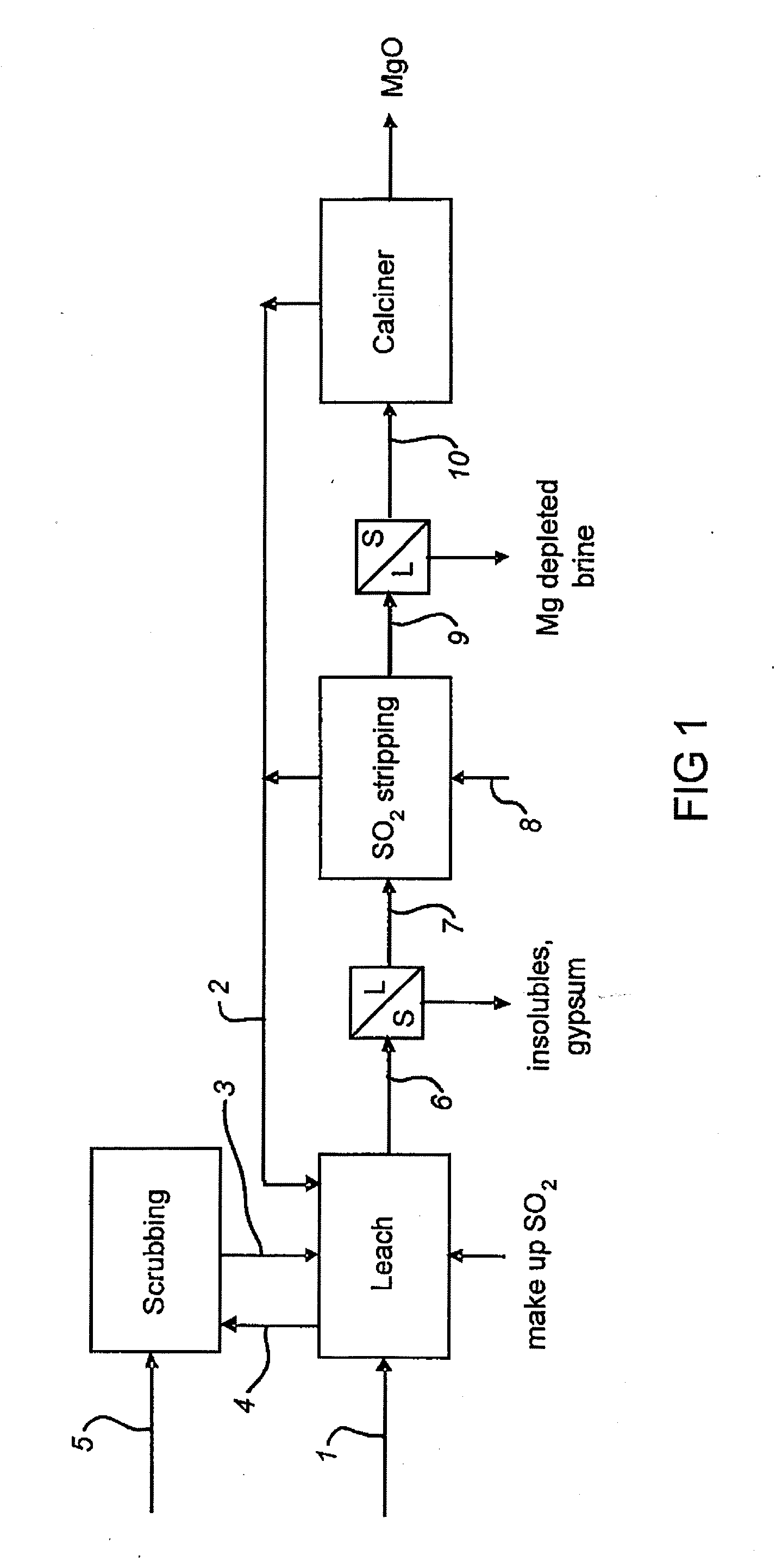

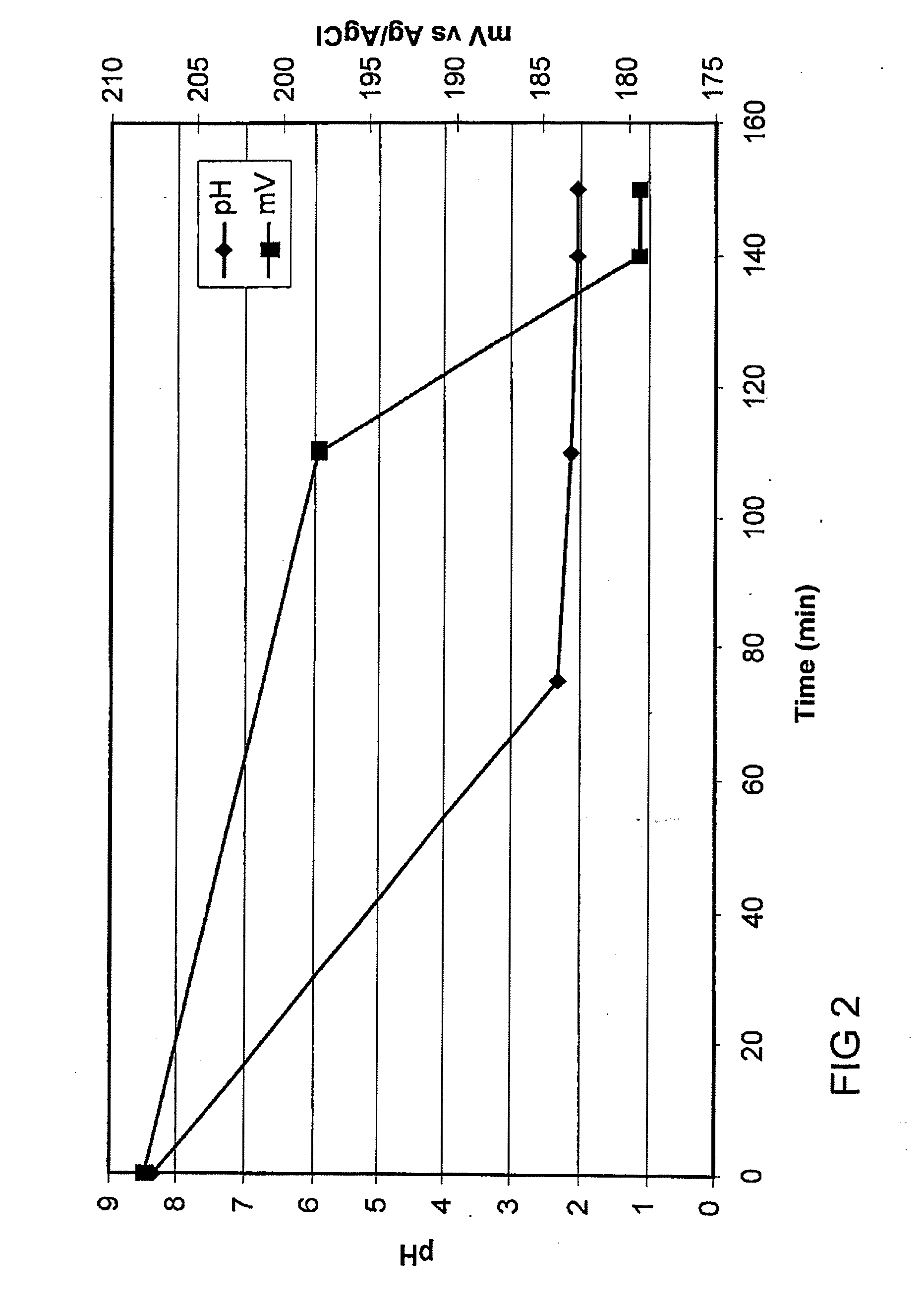

Process for the Production of Magnesium Oxide

InactiveUS20080025892A1Low costEasy to recycleCalcium/strontium/barium compoundsMagnesium sulfitesMagnesium saltPhysical chemistry

A process for the recovery of magnesium oxide from a source containing magnesium salts, said process including the steps of: (a) adding an alkali and sulfur dioxide to the source containing magnesium salts, in a leach step to form a magnesium bi-sulfite containing leachate;(b) separating the insoluble materials from the leachate; (c) stripping excess sulfur dioxide from the leachate and precipitating the magnesium as solid magnesium sulfite hydrate; (d) separating the solid magnesium sulfite hydrate from the magnesium depleted leachate; and (e) calcining the solid magnesium sulfite hydrate and recovering the magnesium as magnesium oxide.

Owner:BHP BILLITON SSM TECH PTY LTD

Metal oxide and metal fluoride nanostructures and methods of making same

InactiveUS7575735B2Easy to controlOvercomes shortcomingMercury oxidesAlkali metal oxides/hydroxidesSingle crystalFluoride

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Process for the preparation of micron/nano sized inorganic material

InactiveUS20080260615A1Economic and efficientMaterial nanotechnologyStrontium carbonatesSuper structureSulfide

The invention discloses methods for making micron / nano meter sized particles of various inorganic materials such as minerals / oxides / sulphides / metals / ceramics at a steadily expanding liquid-liquid interface populated by suitable surfactant molecules that spontaneously organize themselves into superstructures varying over large length-scales. This experiment is realized in a radial Hele-Shaw cell where the liquid-liquid interfacial growth rate and consequently time scales such as arrival of surfactant molecules to the interface, the hydrodynamic flow effect to modulate the material organization into super structures at the dynamic charged interface.

Owner:COUNCIL OF SCI & IND RES

Processes for the production of citric acid

ActiveUS11236033B2High operating temperaturePrevent oxidationPreparation from carboxylic acid saltsCarbon compoundsAlkaline earth metalCarboxylic acid anion

Owner:INNOVATOR ENERGY LLC

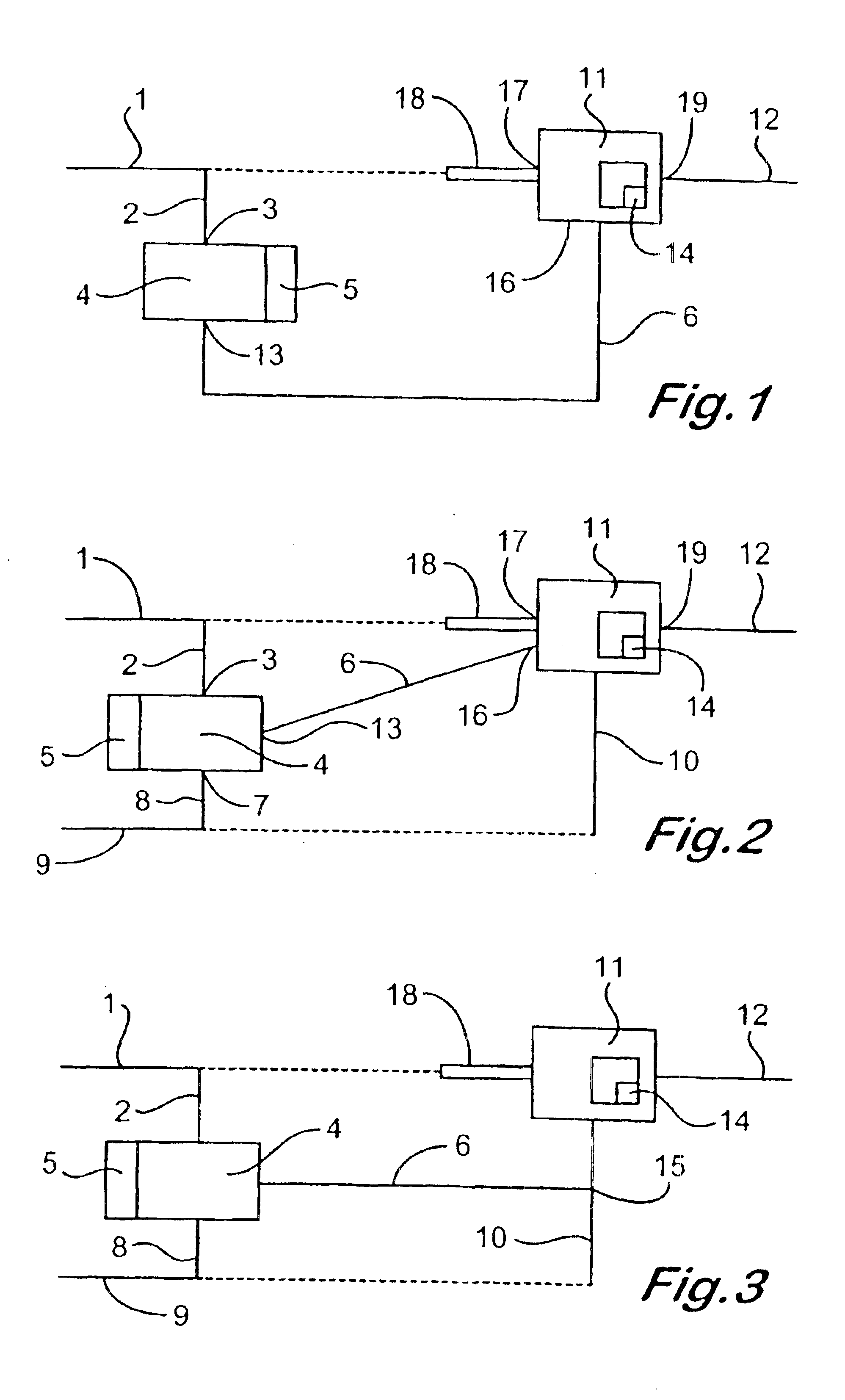

Device and method for producing magnesium sulfite by flue gas desulfurization

ActiveCN104556159ALow running costGuaranteed desulfurization efficiencyMagnesium sulfitesFlue gasMagnesium sulfite

The invention discloses a device and method for producing magnesium sulfite by flue gas desulfurization. The device comprises a flue gas desulfurization device, a slurry circulating pool, a circulating settling tank and the like. The device and method are especially suitable for removing sulfur dioxide in coal burning boiler flue gas and other types of flue gas with low oxygen content, and can generate magnesium sulfite. By adopting the combination mode of multistage absorption, circulating settling and settling tank cooling crystallization, the device and method ensure the desulfurization efficiency and byproduct quality on the premise of thoroughly eliminating the electric power consumption and steam consumption of the oxidation blower, greatly lower the operating cost of the coproduct production system, and reduce the desulfurization operating cost.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

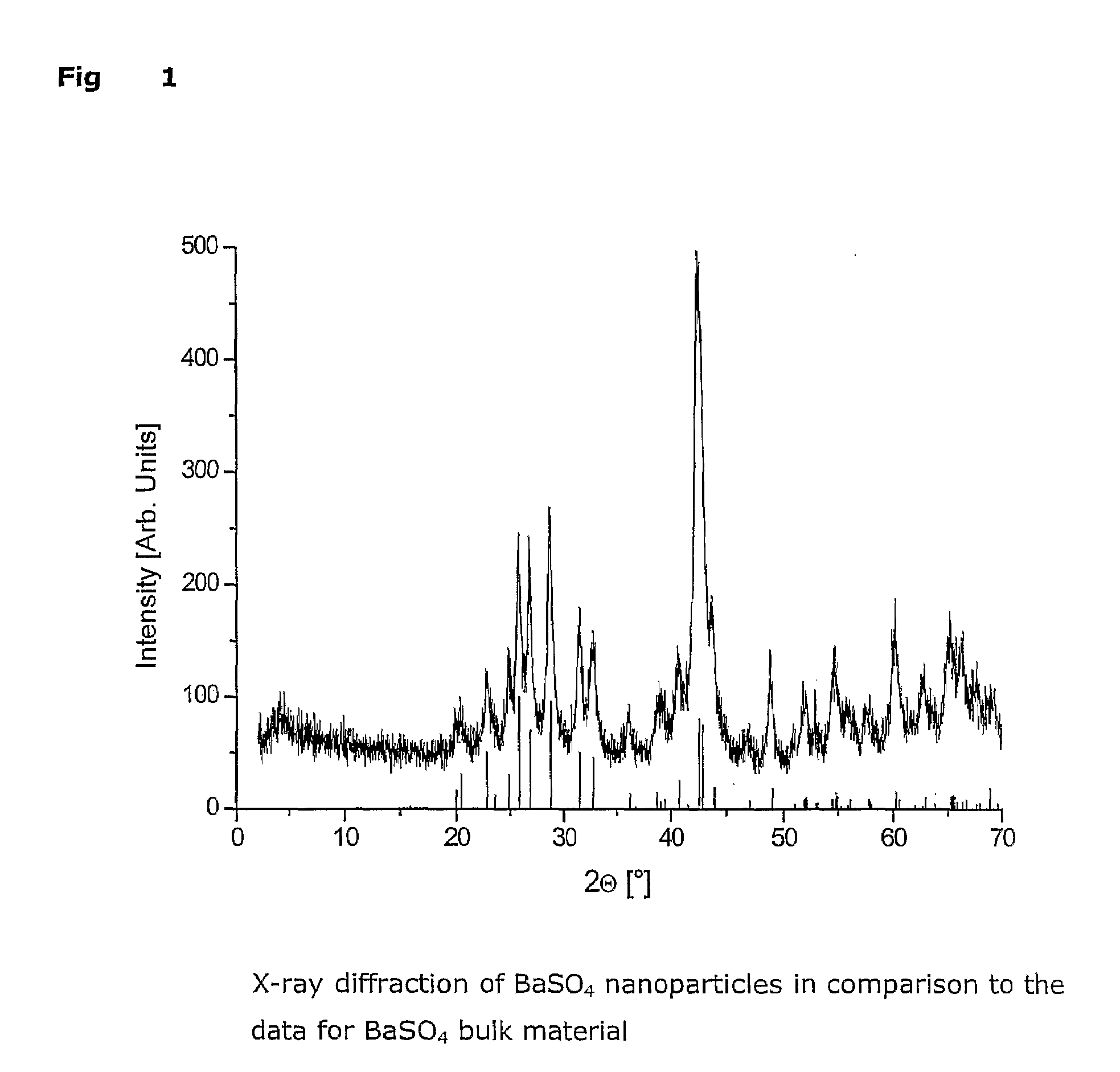

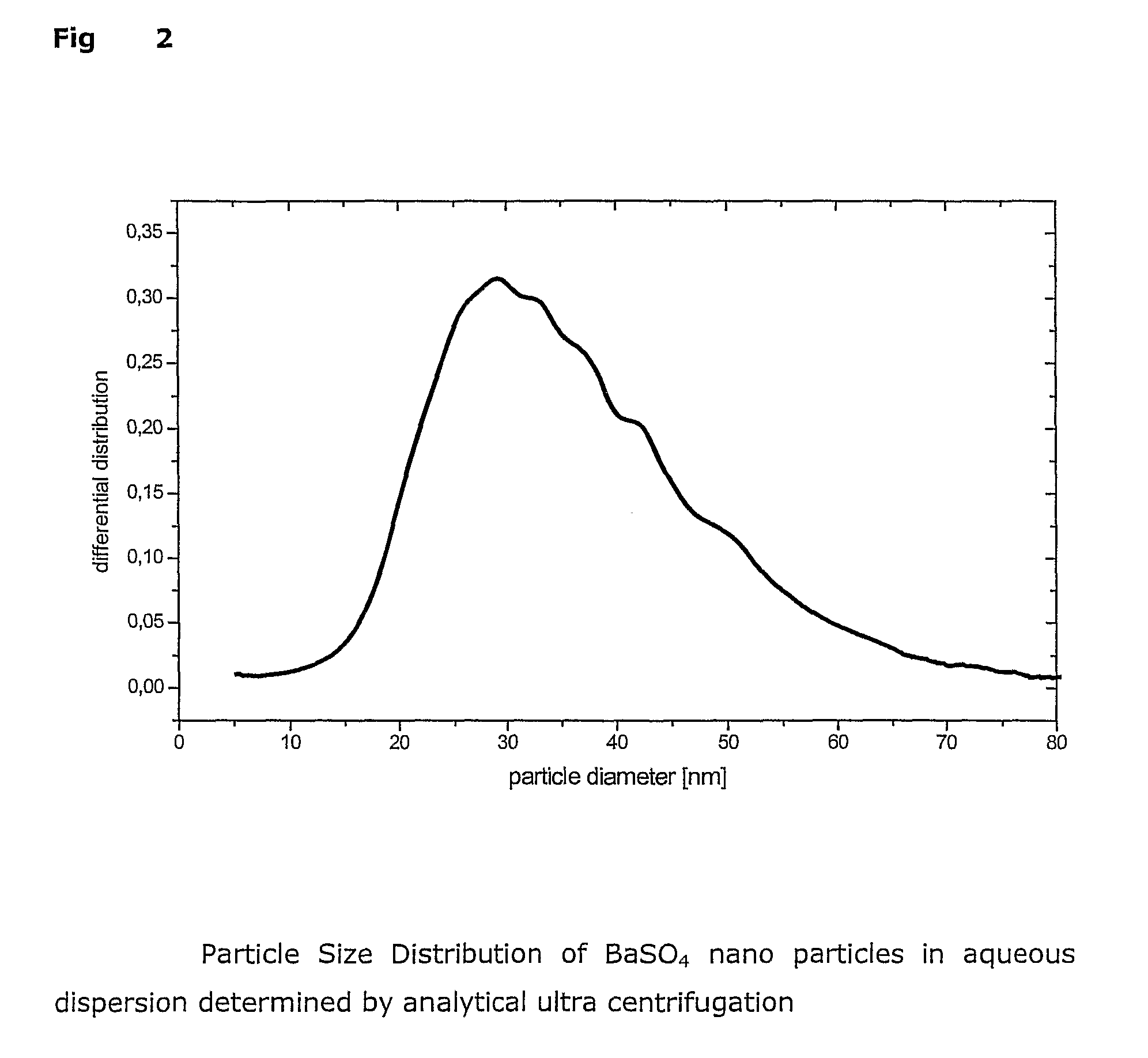

Method for producing alkaline earth sulphate nanoparticles

InactiveUS7288239B2Little has been producedSmall sizePowder deliveryPigmenting treatmentPolyethylene glycolSolvent

The invention relates to synthesis of nanoparticles, in particular to methods for producing nanoparticles with networks consisting of Z sulphate (Z=magnesium (Mg), calcium (Ca), strontium (Sr), barium (Ba) or the binary mixtures thereof). The inventive method consists in synthesising the nanoparticles by crystal growth from an ion Z source and a sulphate ion source in a liquid phase mixture. The invention produces Z sulphate nanoparticles having a small diameter and uniformly dispersible in water or other solvents in a simple way. Co-ordinating solvents like glycerine, glycol ethylene and other polyethylene glycols, polyalcohols or dimethylsulphoxide (DMSO) are used for the synthesis mixture.

Owner:CENT FUR ANGEWANDTE NANOTECH

Viscoelastic surfactant based cleaning compositions

ActiveUS20150218488A1Improve performanceInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSURFACTANT BLENDViscoelasticity

Alkaline or neutral viscoelastic cleaning compositions are disclosed which use non polymer thickening agents. According to the invention, cleaning compositions have been developed using viscoelastic surfactants in a neutral, acidic or alkaline cleaning formulations. These provide the dual benefit of thickening as well as an additional cleaning, thereby improving performance. Applicants have also identified several pseudo linking agents which when, used with viscoelastic surfactants provide viscoelasticity in alkaline cleaning compositions.

Owner:ECOLAB USA INC

Process for preparing dispersible sulfate, preferably barium sulfate nanoparticles

Owner:CENT FUR ANGEWANDTE NANOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com