Nanotube-based high energy material and method

A technology of carbon-based materials and carbon nanotubes, applied in the direction of single-walled carbon nanotubes, nanostructure manufacturing, nanotechnology, etc., can solve problems such as unsatisfied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Detailed description of preferred embodiments

[0026] Through many techniques such as laser melting of carbon targets, decomposition of hydrocarbons, and arc formation between two graphite electrodes, a carbon-based material containing single-walled nanotubes (SWNT) can be formed.

[0027] For example, in C. Bower et al., Synthesis and Structure of Pristine and Cesium Intercalated Single-Walled Carbon Nanotubes, Applied Physics: A67, pp. 47-52, spring 1998. The literature describes a suitable technique for producing SWNT bundles. , The entire content of its disclosure is incorporated herein by reference.

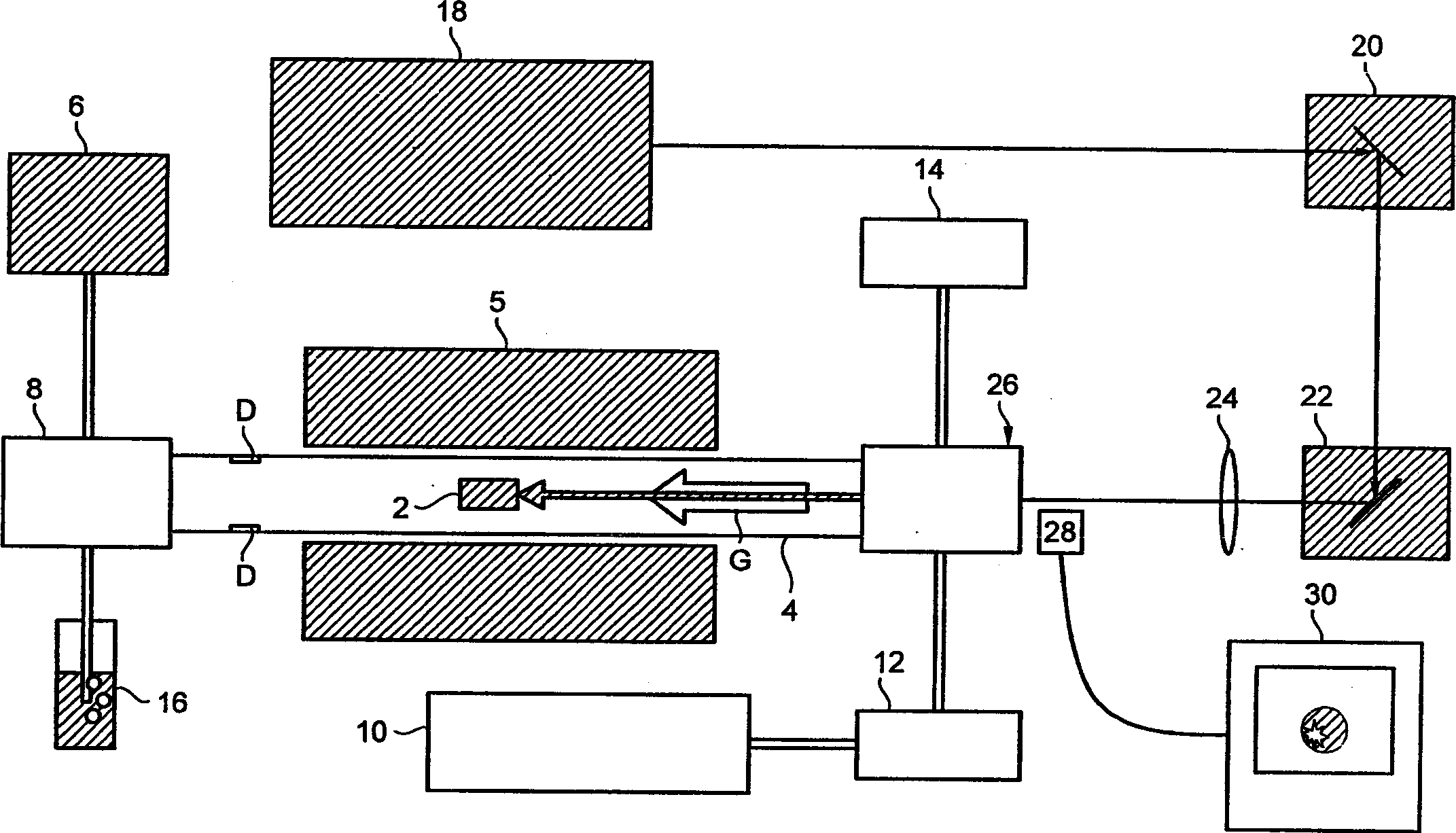

[0028] Such as figure 1 As shown, a suitable target 2 is placed in the quartz tube 4 according to this technique. Preferably, the target 2 is made of graphite and contains a Ni / Co catalyst. In a preferred embodiment, the target is formed of graphite powder mixed with 0.6 atomic% Ni and 0.6 atomic% Co and a graphite binder.

[0029] A vacuum pump 6 connected to one end o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com