Technique for preparing magnesium sulfite during magnesium method desulfurization process

A magnesium sulfite and magnesium desulfurization technology, applied in the direction of magnesium sulfite, separation methods, chemical instruments and methods, etc., can solve the problems of reducing the output of by-products, waste of resources, high solubility, etc., and achieve complete solid-liquid separation, easy adsorption, Effect of Yield Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

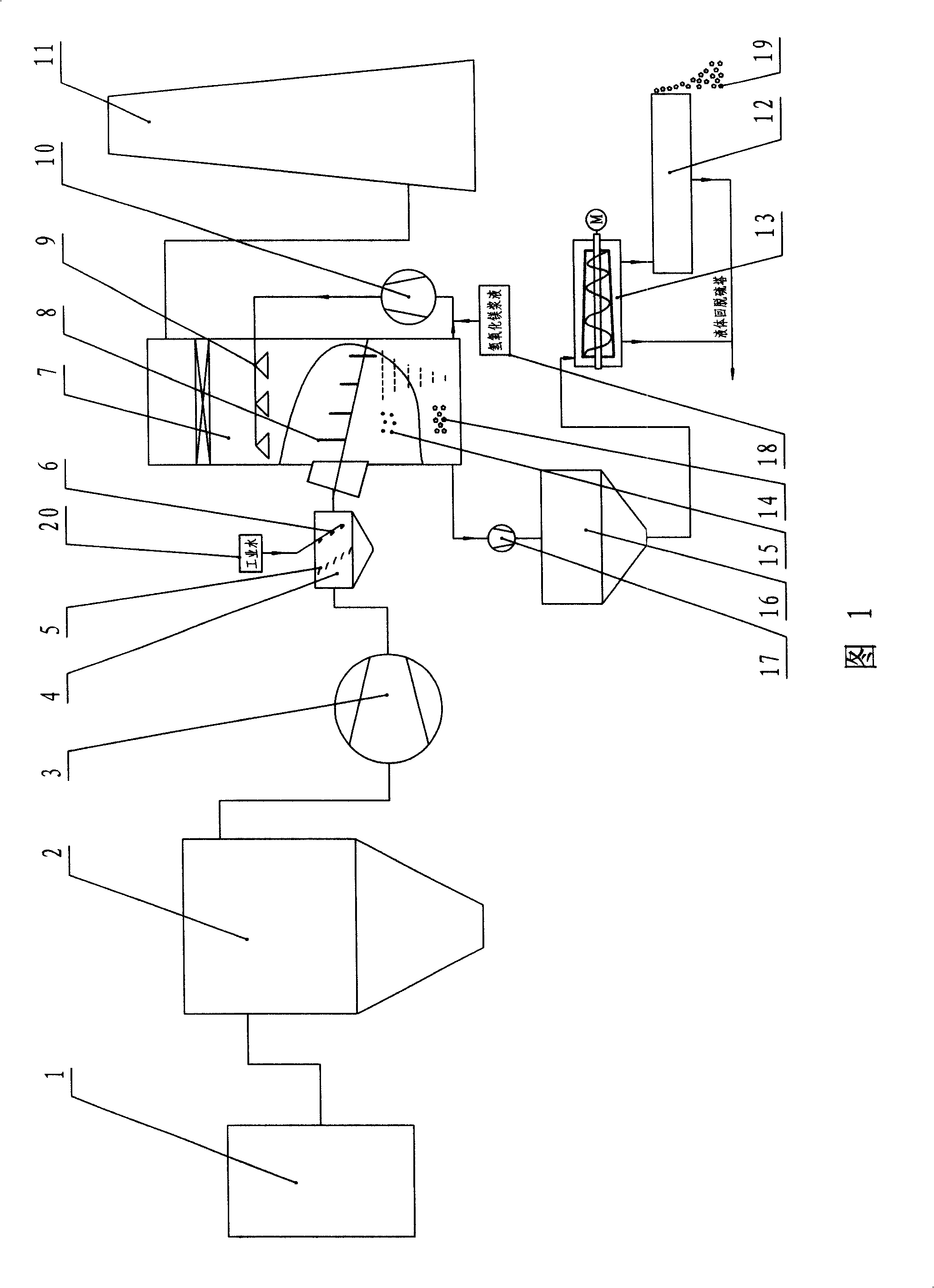

[0022] The preparation technology of magnesium sulfite in the magnesium method desulfurization process of the present invention, its step comprises:

[0023] ① Removal of impurities: introduce the flue gas containing sulfur dioxide into the pretreatment device, so that part of the fine dust, hydrogen chloride and hydrogen fluoride in the flue gas will be removed by the atomized water sprayed by the spraying device when the flue gas passes through the pretreatment device, and then the flue gas sent to the desulfurization tower;

[0024] ② Desulfurization: The sulfur dioxide in the flue gas reacts with the magnesium hydroxide slurry in the desulfurization tower, thereby removing the sulfur dioxide in the flue gas;

[0025] ③Separation: The slurry formed by desulfurization is flocculated and precipitated, and then the precipitate is subjected to solid-liquid separation;

[0026] In the desulfurization process described in step ②, the oxidation inhibitor elemental sulfur or sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com